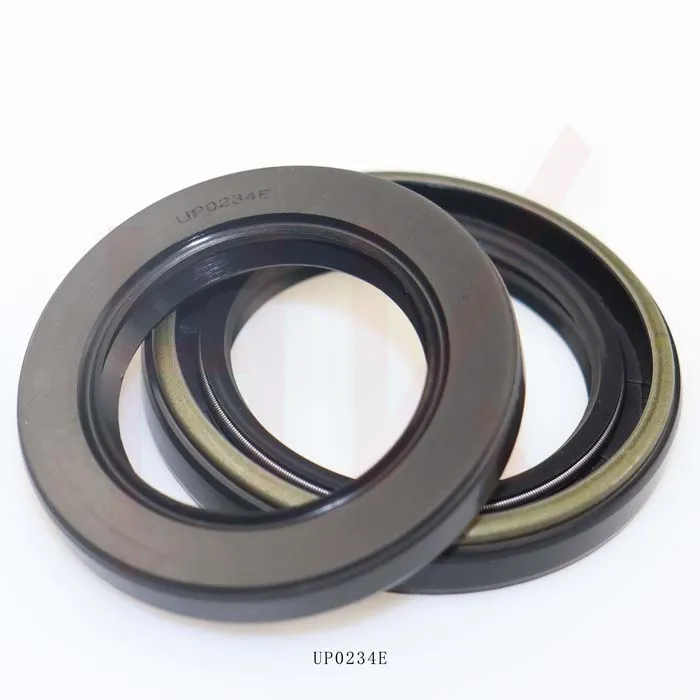

Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel

Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel front hub oil seal. If detected early, these issues can be addressed before they escalate into more significant problems.

front hub oil seal. If detected early, these issues can be addressed before they escalate into more significant problems.