Current location:Home > oil seal >

oil seal

2025-08-14 08:29

2025-08-14 08:11

2025-08-14 08:04

...

2025-08-14 07:52

Another factor that can contribute to oil seal failure is contamination. Around 47% of oil seals fail due to contamination by dirt, debris, or other particles. This can cause the seal to wear out quickly and lose its effectiveness. Regularly cleaning and inspecting the seals can help prevent contamination and prolong their lifespan

25 47 7 oil seal.

25 47 7 oil seal.

...

2025-08-14 07:36

2025-08-14 07:10

2025-08-14 07:09

3. Pressure Maintenance In many applications, oil seals are designed to maintain pressure within a system. By preventing the exit of oil and the entrance of contaminants, they help in sustaining the necessary pressure levels for optimal operation. This function is especially important in hydraulic systems, where pressure plays a critical role in performance.

what is the function of oil seal

...

2025-08-14 06:43

2025-08-14 06:14

2025-08-14 05:56

Latest articles

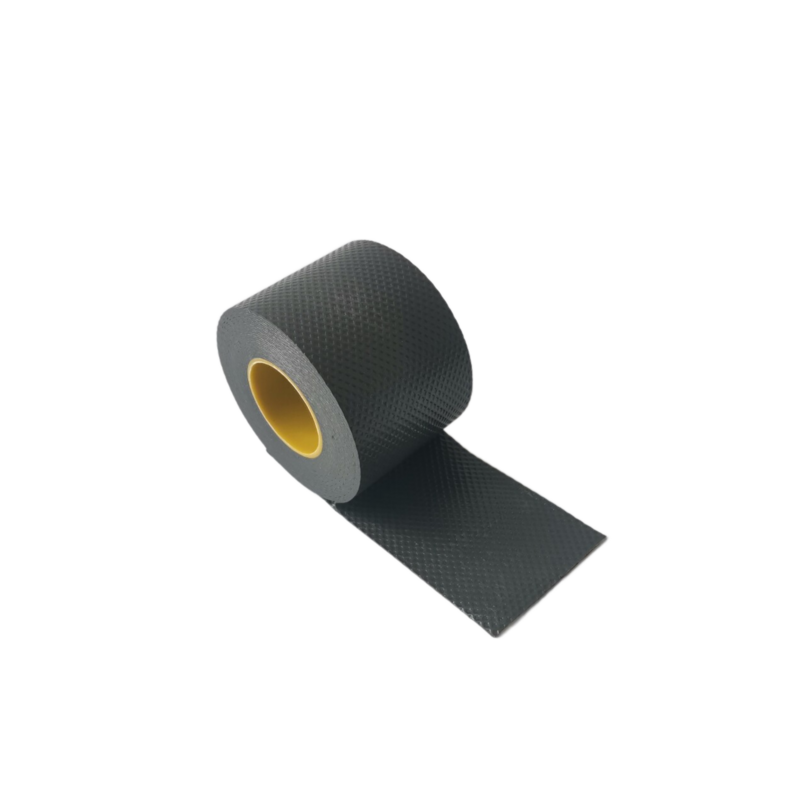

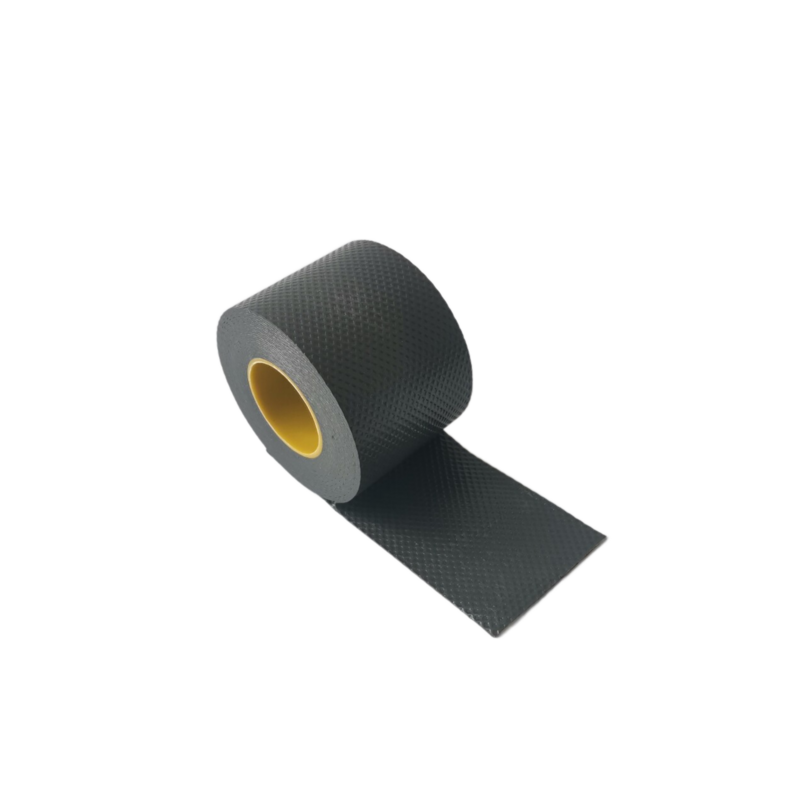

In addition to its use in construction and automotive applications, butyl tape rubber is also used in the manufacturing of various products, such as electronics, appliances, and consumer goods. The tape is often used for sealing and insulating electrical components and connections, as it can provide a reliable and long-lasting seal that protects against moisture and corrosion

butyl tape rubber.

butyl tape rubber.