Current location:Home > gear box seal kit >

gear box seal kit

2025-08-14 21:53

2025-08-14 21:53

2025-08-14 21:27

There are various types of hydraulic shaft seals available, each designed to suit different applications and operating conditions. Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings

Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings hydraulic shaft seal. Lip seals are simple in design and are suitable for low-pressure applications, while mechanical face seals are more complex and are capable of handling high-pressure and high-speed conditions. O-rings are another popular option for hydraulic sealing, providing a cost-effective solution for many applications.

hydraulic shaft seal. Lip seals are simple in design and are suitable for low-pressure applications, while mechanical face seals are more complex and are capable of handling high-pressure and high-speed conditions. O-rings are another popular option for hydraulic sealing, providing a cost-effective solution for many applications.

Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings

Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings Common types of hydraulic seals include lip seals, mechanical face seals, and o-rings hydraulic shaft seal. Lip seals are simple in design and are suitable for low-pressure applications, while mechanical face seals are more complex and are capable of handling high-pressure and high-speed conditions. O-rings are another popular option for hydraulic sealing, providing a cost-effective solution for many applications.

hydraulic shaft seal. Lip seals are simple in design and are suitable for low-pressure applications, while mechanical face seals are more complex and are capable of handling high-pressure and high-speed conditions. O-rings are another popular option for hydraulic sealing, providing a cost-effective solution for many applications.

...

2025-08-14 21:11

2025-08-14 21:03

2025-08-14 20:53

2025-08-14 20:45

2025-08-14 20:38

One of the key benefits of high pressure rotary shaft seals is their ability to operate in extreme conditions without compromising performance. They can withstand pressures of up to several thousand psi, making them ideal for applications such as hydraulic systems, compressors, pumps, and motors. In addition, these seals are resistant to wear and tear, ensuring long-lasting performance even in demanding environments.

...

2025-08-14 20:20

The manufacturing process of oil seals involves several steps, starting with the selection of the raw materials. Synthetic rubber is the most commonly used material for oil seals, as it offers excellent sealing properties and flexibility

25 47 7 oil seal. Metal oil seals, on the other hand, are preferred for high-temperature applications where resistance to heat is crucial.

25 47 7 oil seal. Metal oil seals, on the other hand, are preferred for high-temperature applications where resistance to heat is crucial.

...

2025-08-14 19:45

Latest articles

2. Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants

Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants oil seal for rotating shaft. They are ideal for high-speed applications or where increased contamination resistance is required.

oil seal for rotating shaft. They are ideal for high-speed applications or where increased contamination resistance is required.

Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants

Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants Double Lip Seals These seals have two sealing lips, offering enhanced protection against both lubricant leakage and ingress of contaminants oil seal for rotating shaft. They are ideal for high-speed applications or where increased contamination resistance is required.

oil seal for rotating shaft. They are ideal for high-speed applications or where increased contamination resistance is required.The importance of cylinder oil seals becomes most evident when they fail. Symptoms of a worn or damaged seal include oil stains on the garage floor, blue smoke emanating from the exhaust during acceleration, and a noticeable drop in oil level over time. These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure

These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure cylinder oil seal.

cylinder oil seal.

These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure

These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure These signs should prompt immediate action, as neglecting this issue can lead to more severe problems like scoring of cylinder walls or even catastrophic engine failure cylinder oil seal.

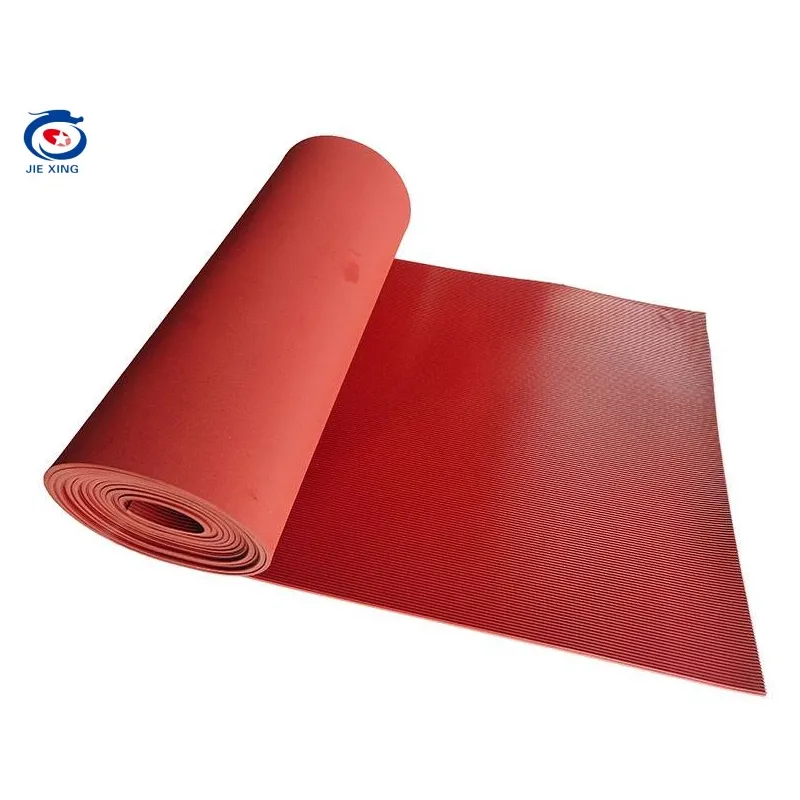

cylinder oil seal.In the hospitality sector, slipping mats are equally vital. Restaurants, hotels, and bars often deal with spills and wet surfaces, creating an environment ripe for accidents. Slipping mats placed strategically in kitchens, at bars, and near entrances can provide a barrier against slipping hazards. Moreover, these mats are available in various styles and designs, allowing businesses to maintain aesthetic appeal without sacrificing safety. This dual focus on safety and aesthetics is critical in attracting and retaining customers.

slipping mat