Demand dynamics also play a significant role in the pricing of oil seals. As global industries recover from economic downturns, the demand for machinery and vehicles tends to rise. This increased demand for oil seals can lead to higher prices if supply cannot keep pace. For example, during the economic recovery following the COVID-19 pandemic, many industries saw a surge in demand for automotive parts, including oil seals, straining the supply chains and driving prices upward. Moreover, the increasing trend toward electric vehicles, while potentially reducing some demand for traditional oil seals, has sparked interest in specialized seals for new technologies, which can also influence market prices.

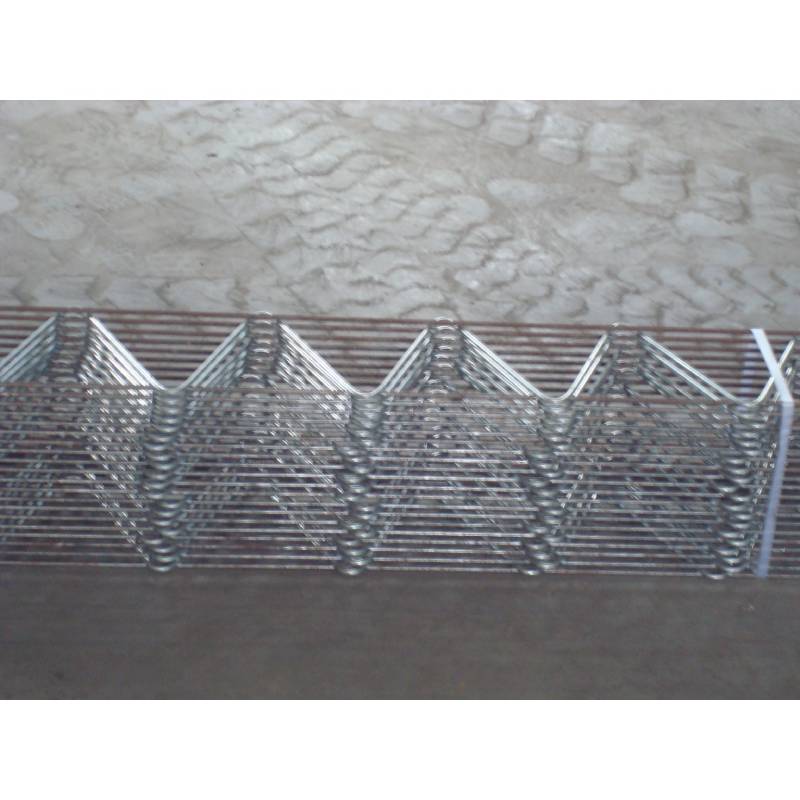

High-quality seals act as a barrier, keeping contaminants out and ensuring that the system operates smoothly without interruption High-quality seals act as a barrier, keeping contaminants out and ensuring that the system operates smoothly without interruption

High-quality seals act as a barrier, keeping contaminants out and ensuring that the system operates smoothly without interruption High-quality seals act as a barrier, keeping contaminants out and ensuring that the system operates smoothly without interruption hydraulic seal kits.

hydraulic seal kits.