Current location:Home > Hebei Hankai hydraulic cylinder dust seal >

Hebei Hankai hydraulic cylinder dust seal

...

2025-08-16 17:53

1. Automotive Industry In vehicles, oil seals are crucial for various components, including the engine, transmission, and differential. The 20x35x7 oil seal can effectively prevent engine oil from leaking out, which is essential for maintaining lubrication and preventing damage to engine parts.

20x35x7 oil seal

...

2025-08-16 17:38

2025-08-16 17:23

2. Contaminant Protection Grease seals act as a first line of defense against contaminants. Dust, water, and debris can enter the bearing assembly and potentially lead to corrosion, pitting, and other forms of wear. By keeping these contaminants out, grease seals help maintain the integrity of the bearings.

wheel bearing grease seal

...

2025-08-16 17:03

2025-08-16 16:12

2025-08-16 16:08

2025-08-16 16:01

2025-08-16 15:36

Regular maintenance and replacement of seals in hydraulic cylinders are essential to prevent leaks and ensure the longevity of the equipment

2 inch hydraulic cylinder seal kit. By investing in a high-quality 2-inch hydraulic cylinder seal kit, operators can minimize downtime, reduce repair costs, and extend the lifespan of their hydraulic systems.

2 inch hydraulic cylinder seal kit. By investing in a high-quality 2-inch hydraulic cylinder seal kit, operators can minimize downtime, reduce repair costs, and extend the lifespan of their hydraulic systems.

...

2025-08-16 15:33

2025-08-16 15:29

Latest articles

After the damaged seal has been removed, it is important to clean the area thoroughly to ensure that the new seal will seal properly

hydraulic cylinder seal repair. Any debris or contaminants should be removed from the cylinder to prevent future leaks.

hydraulic cylinder seal repair. Any debris or contaminants should be removed from the cylinder to prevent future leaks.

The benefits of using the 35x52x7 oil seal are numerous 35x52x7 oil seal. Firstly, it provides reliable and long-lasting protection against leakage and contamination, reducing maintenance costs and downtime. Secondly, its compact size makes it easy to install and replace, saving time and effort for technicians. Thirdly, it offers excellent compatibility with various types of oils and lubricants, ensuring optimal performance across different applications.

35x52x7 oil seal. Firstly, it provides reliable and long-lasting protection against leakage and contamination, reducing maintenance costs and downtime. Secondly, its compact size makes it easy to install and replace, saving time and effort for technicians. Thirdly, it offers excellent compatibility with various types of oils and lubricants, ensuring optimal performance across different applications.

35x52x7 oil seal. Firstly, it provides reliable and long-lasting protection against leakage and contamination, reducing maintenance costs and downtime. Secondly, its compact size makes it easy to install and replace, saving time and effort for technicians. Thirdly, it offers excellent compatibility with various types of oils and lubricants, ensuring optimal performance across different applications.

35x52x7 oil seal. Firstly, it provides reliable and long-lasting protection against leakage and contamination, reducing maintenance costs and downtime. Secondly, its compact size makes it easy to install and replace, saving time and effort for technicians. Thirdly, it offers excellent compatibility with various types of oils and lubricants, ensuring optimal performance across different applications.Navigating the world of automatic paint spraying equipment unveils a delicate balance between technology

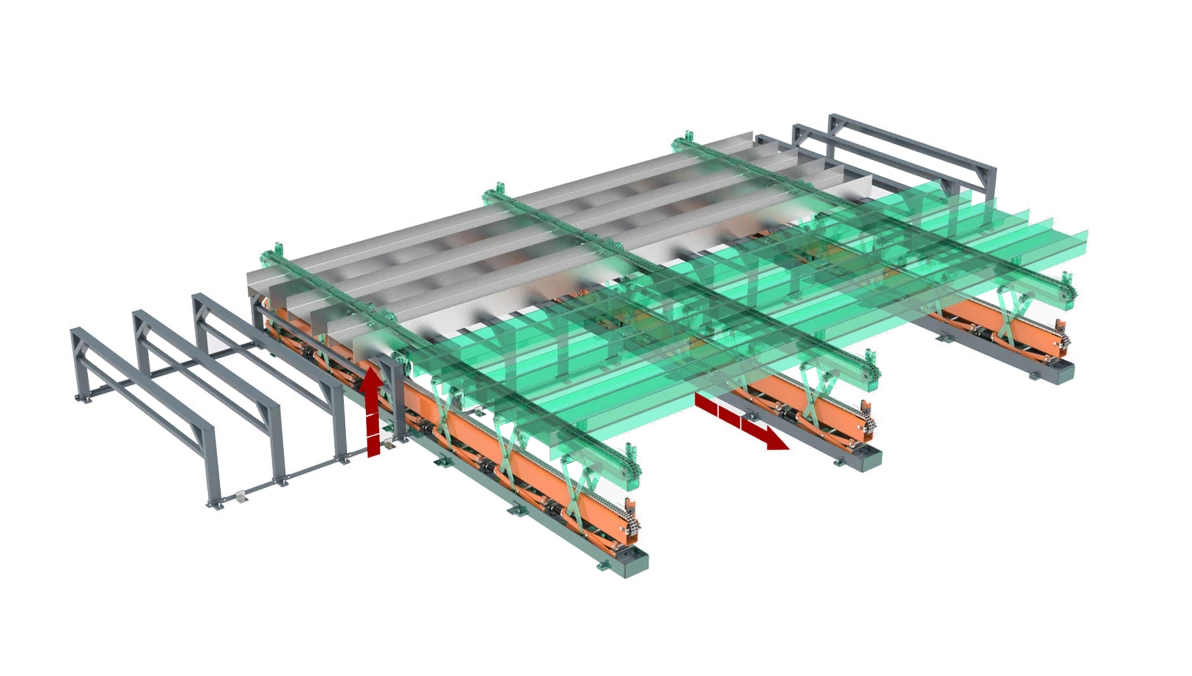

, precision, and artistry. In today's rapidly evolving manufacturing landscape, the demand for higher efficiency, consistent quality, and enhanced scalability has exponentially increased the reliance on this equipment. As industries across the globe increasingly seek automation, understanding the nuances of automatic paint systems has become imperative for anyone looking to optimize production lines and maintain a competitive edge.