Hebei Hankai 5 inch hydraulic cylinder seal kit

22x35x7 oil seal. Its lip design provides a dynamic sealing solution that adapts to shaft movement, reducing wear and tear over time. Some variants might include a reinforcing spring to provide additional resilience against heavy vibration and mechanical shocks, making them suitable for use in vehicles and industrial equipment subjected to harsh operating conditions.

22x35x7 oil seal. Its lip design provides a dynamic sealing solution that adapts to shaft movement, reducing wear and tear over time. Some variants might include a reinforcing spring to provide additional resilience against heavy vibration and mechanical shocks, making them suitable for use in vehicles and industrial equipment subjected to harsh operating conditions.

rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation.

rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation. Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.Rolled steel bars are used in conjunction with concrete blocks to provide additional strength and support. These bars are commonly integrated into concrete block walls to reinforce their structural capacity and resist bending or deformation. When selecting rolled steel bars, it is important to choose the appropriate size and grade based on the load-bearing requirements of your project. Proper placement and secure anchoring of these bars are crucial for achieving the desired stability and durability of the concrete blocks.

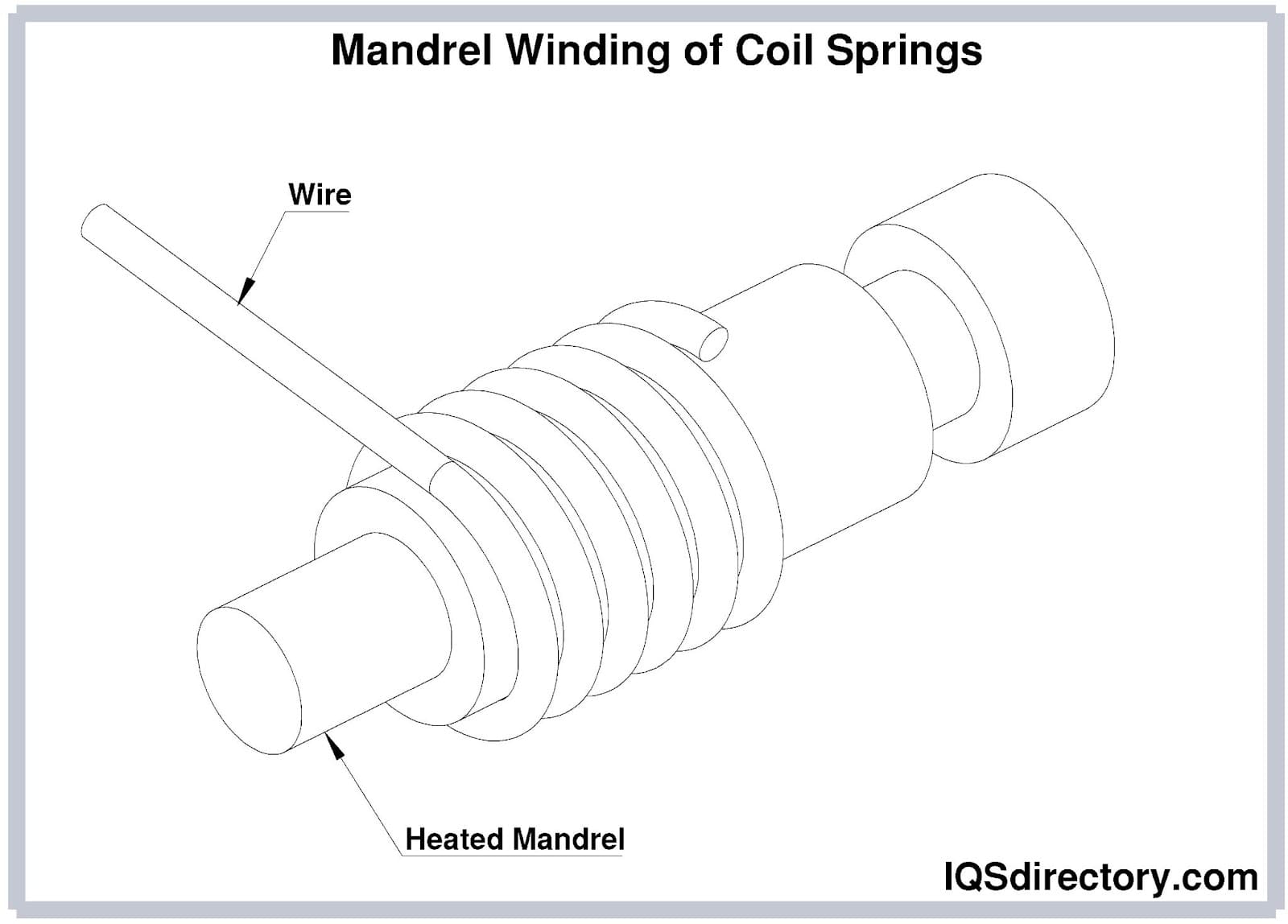

Mandrel –A mandrel is one of the two primary methods for manufacturing coil springs. This process can be carried out using a lathe, winding machine, or hand crank machine. During production, a guide mechanism ensures that the wire is aligned correctly to achieve the desired pitch, which is the spacing between the coils as they are wrapped.