Current location:Home > excavator seal kit >

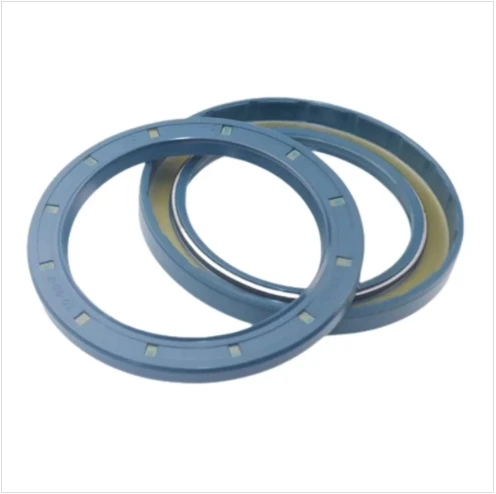

excavator seal kit

2025-08-15 18:20

2025-08-15 17:49

2025-08-15 16:56

2025-08-15 16:53

2025-08-15 16:38

2025-08-15 16:17

2025-08-15 16:17

2025-08-15 16:09

2025-08-15 16:02

2025-08-15 16:02

Latest articles

The primary function of these seal kits is to maintain system cleanliness and ensure leak-free operation. A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.Once the graphics are finalized, manufacturers move to the creation of the tin boxes themselves. The process involves cutting and shaping sheets of steel, which are coated with a layer of tin to prevent rusting and ensure durability. The pieces are then pressed into shape and assembled—usually featuring a hinged lid and a sturdy handle, reminiscent of the lunch boxes popularized in the mid-20th century.

star wars tin lunch box manufacturer