Current location:Home > oil seal factory >

oil seal factory

2025-08-14 07:16

2025-08-14 06:52

Replacing hydraulic seals is a meticulous task that requires precision and expertise. The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation

The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation hydraulic seal replacement. Once identified, the system should be drained and isolated to prevent fluid spills and ensure safe working conditions. The old seal is then carefully removed without damaging surrounding parts.

hydraulic seal replacement. Once identified, the system should be drained and isolated to prevent fluid spills and ensure safe working conditions. The old seal is then carefully removed without damaging surrounding parts.

The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation

The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation The first step involves identifying the worn or damaged seal, which might show signs like visible wear, cracking, or deformation hydraulic seal replacement. Once identified, the system should be drained and isolated to prevent fluid spills and ensure safe working conditions. The old seal is then carefully removed without damaging surrounding parts.

hydraulic seal replacement. Once identified, the system should be drained and isolated to prevent fluid spills and ensure safe working conditions. The old seal is then carefully removed without damaging surrounding parts.

...

2025-08-14 06:27

2025-08-14 06:21

Furthermore, dust lip seals also contribute to the overall efficiency and reliability of machinery

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

...

2025-08-14 06:06

2025-08-14 05:52

2025-08-14 05:47

2025-08-14 05:38

2025-08-14 05:05

Latest articles

One common type of oil seal is the 25% 47% 7% oil seal, which is specifically designed to withstand high temperatures and pressures. This makes it suitable for use in heavy-duty applications such as automotive engines, industrial pumps, and hydraulic systems. The 25% 47% 7% oil seal is known for its durability, reliability, and resistance to wear and tear, making it a popular choice among engineers and manufacturers.

In addition to improving strength, brick reinforcement mesh also enhances the impact resistance of a brick wall. By reinforcing the mortar joints between bricks, the mesh helps to absorb and disperse the force of impact, reducing the likelihood of damage from accidental bumps or collisions. This can be particularly important in high-traffic areas or in buildings where impact resistance is a primary concern.

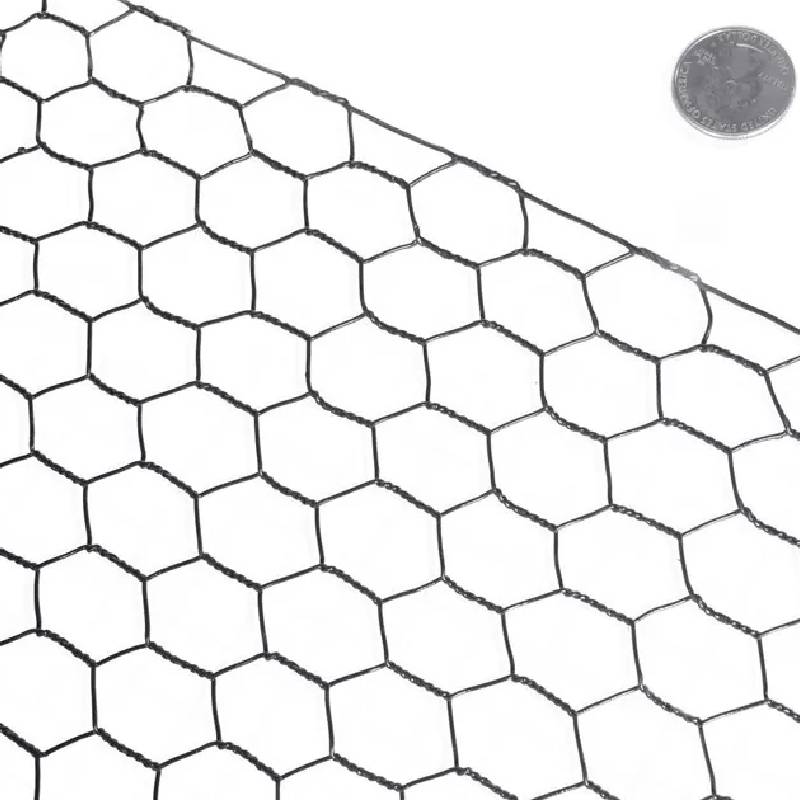

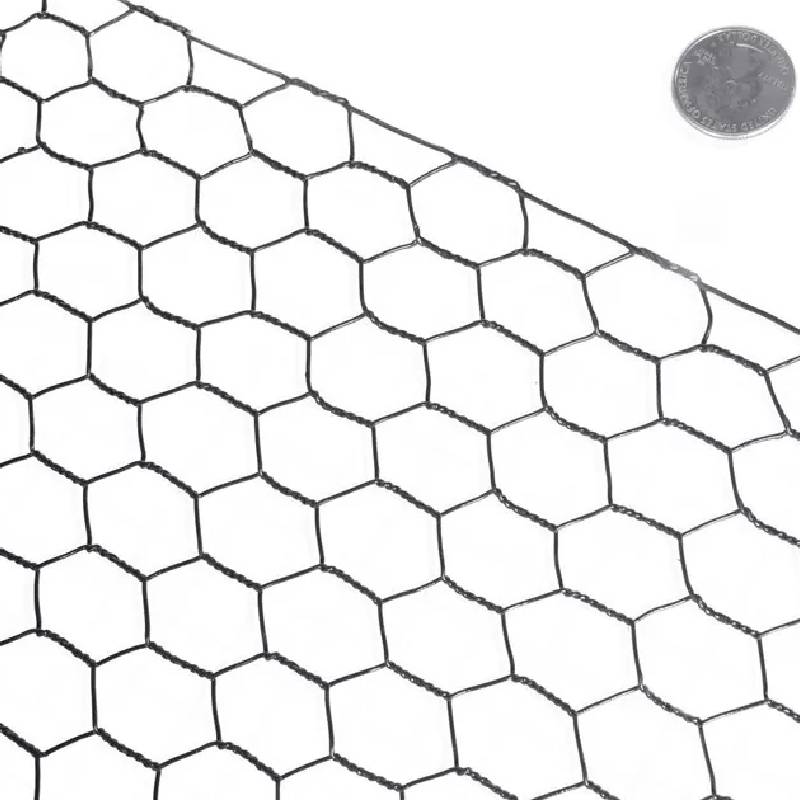

Despite its affordability, wholesale chicken wire fencing is still highly effective at keeping animals contained. The small mesh size prevents animals from squeezing through or getting caught in the fence, while the galvanized steel construction resists rust and corrosion, ensuring the longevity of the fencing even in harsh weather conditions

wholesale chicken wire fencing.

wholesale chicken wire fencing.