Current location:Home > Hebei Hankai hydraulic lip seal >

Hebei Hankai hydraulic lip seal

2025-08-14 04:13

2025-08-14 04:04

2025-08-14 04:03

2025-08-14 03:32

2025-08-14 03:27

2025-08-14 03:11

2025-08-14 03:08

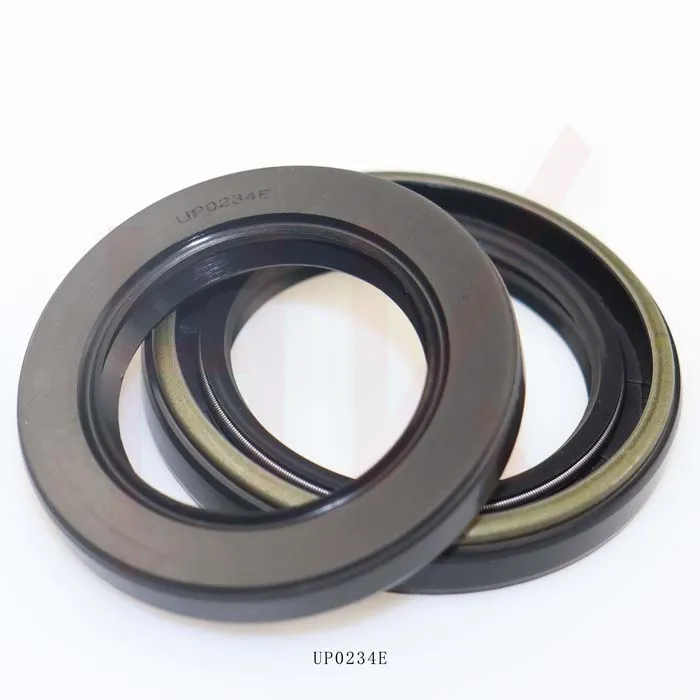

The material selection for oil seals is crucial as it determines their performance, durability, and compatibility with various fluids. Common materials used in oil seals include nitrile rubber, fluoroelastomers, silicone rubber, and polytetrafluoroethylene (PTFE). Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range

Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range oil seal tcn. Fluoroelastomers, such as Viton, offer excellent chemical and heat resistance but are more expensive. Silicone rubber is known for its flexibility and resistance to extreme temperatures, while PTFE is highly resistant to chemicals and has low friction coefficients.

oil seal tcn. Fluoroelastomers, such as Viton, offer excellent chemical and heat resistance but are more expensive. Silicone rubber is known for its flexibility and resistance to extreme temperatures, while PTFE is highly resistant to chemicals and has low friction coefficients.

Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range

Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range Nitrile rubber is widely used due to its good chemical resistance, oil resistance, and moderate temperature range oil seal tcn. Fluoroelastomers, such as Viton, offer excellent chemical and heat resistance but are more expensive. Silicone rubber is known for its flexibility and resistance to extreme temperatures, while PTFE is highly resistant to chemicals and has low friction coefficients.

oil seal tcn. Fluoroelastomers, such as Viton, offer excellent chemical and heat resistance but are more expensive. Silicone rubber is known for its flexibility and resistance to extreme temperatures, while PTFE is highly resistant to chemicals and has low friction coefficients.

...

2025-08-14 02:39

2025-08-14 02:13

In the automotive industry, TCV seals are an essential component in modern fuel-injected engines. They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance

They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance tcv seal. In industrial applications, such as pumps, compressors, and hydraulic systems, TCV seals are equally vital, preventing fluid loss and maintaining system stability.

tcv seal. In industrial applications, such as pumps, compressors, and hydraulic systems, TCV seals are equally vital, preventing fluid loss and maintaining system stability.

They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance

They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance tcv seal. In industrial applications, such as pumps, compressors, and hydraulic systems, TCV seals are equally vital, preventing fluid loss and maintaining system stability.

tcv seal. In industrial applications, such as pumps, compressors, and hydraulic systems, TCV seals are equally vital, preventing fluid loss and maintaining system stability.

...

2025-08-14 02:05

Latest articles

Button bits are available in a variety of shapes and sizes to suit different drilling applications and rock types. The selection of the right type of button bit is crucial in ensuring the success of the drilling operation

button bit for rock drilling. Factors such as rock hardness, abrasiveness, and the desired drilling speed all play a role in determining the most suitable button bit for the job.

button bit for rock drilling. Factors such as rock hardness, abrasiveness, and the desired drilling speed all play a role in determining the most suitable button bit for the job.