Current location:Home > cfw oil seal >

cfw oil seal

2025-08-16 05:38

2025-08-16 05:35

2025-08-16 05:05

2025-08-16 04:51

2025-08-16 04:44

2025-08-16 04:38

2025-08-16 04:29

2025-08-16 04:28

2025-08-16 03:36

2025-08-16 03:19

Latest articles

Meanwhile, the smaller player with a 7% share adopts a niche strategy, concentrating on specialized areas like renewable energy equipment and eco-friendly vehicles 22 40 7 oil seal. Despite their smaller presence, they have gained a loyal customer base by offering bespoke oil seal solutions that cater to the green revolution's requirements.

22 40 7 oil seal. Despite their smaller presence, they have gained a loyal customer base by offering bespoke oil seal solutions that cater to the green revolution's requirements.

22 40 7 oil seal. Despite their smaller presence, they have gained a loyal customer base by offering bespoke oil seal solutions that cater to the green revolution's requirements.

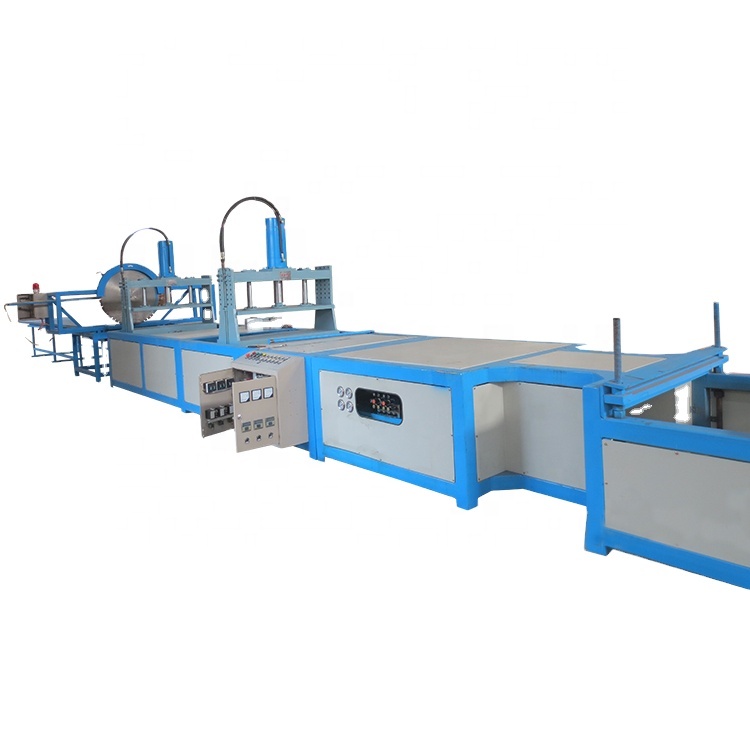

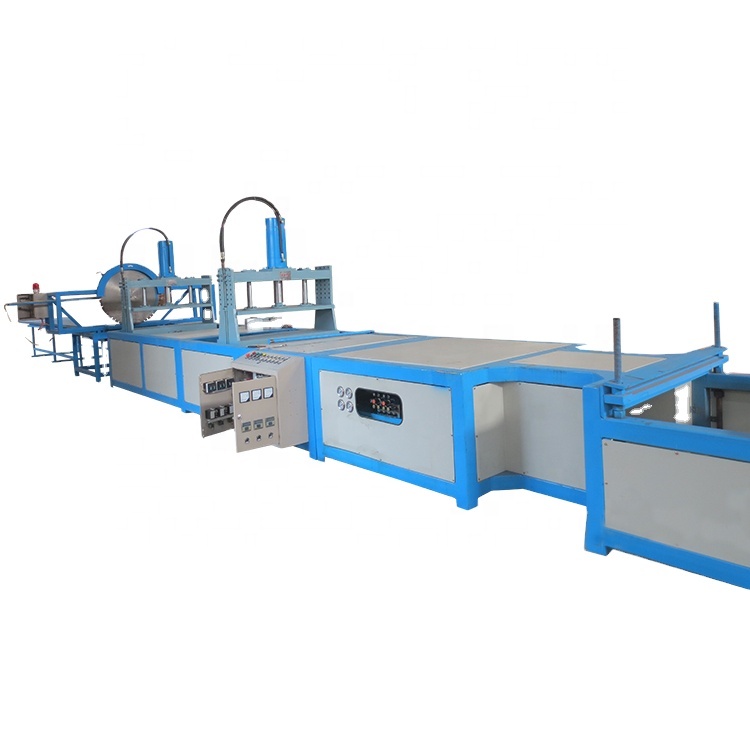

22 40 7 oil seal. Despite their smaller presence, they have gained a loyal customer base by offering bespoke oil seal solutions that cater to the green revolution's requirements.The die or mold is the centerpiece of the pultrusion equipment. It is designed according to the cross-sectional profile of the desired composite part. As the wet-out fibers pass through the heated die, the resin begins to cure, solidifying the composite into its final shape. The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product

The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product pultrusion equipment.

pultrusion equipment.

The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product

The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product The die's internal heating system ensures a consistent cure rate, preventing any inconsistencies in the final product pultrusion equipment.

pultrusion equipment.The steam that has given up its heat now condenses back into liquid form and is collected at the bottom of the tower grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.

grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.

grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.

grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.