Current location:Home > Hebei Hankai hydraulic piston oil seals >

Hebei Hankai hydraulic piston oil seals

2025-08-16 02:25

2025-08-16 02:25

2025-08-16 02:03

2025-08-16 01:58

2025-08-16 01:54

2025-08-16 01:18

2025-08-16 00:47

2025-08-16 00:37

Once the type of seal has been identified, the next step is to remove the old seal from the system. This can be a delicate process, as care must be taken not to damage any other components of the hydraulic system. In some cases, specialized tools may be required to safely and effectively remove the seal.

...

2025-08-16 00:18

2025-08-16 00:14

Latest articles

The importance of a well-functioning hub grease seal cannot be overstated. In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication

In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.

hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.

In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication

In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.

hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.For example, polyurethane is known for its excellent abrasion resistance and ability to maintain its seal under varying temperatures. Nitrile rubber, on the other hand, provides a good balance of chemical resistance and cost-effectiveness. Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance hydraulic seal kits.

hydraulic seal kits.

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance hydraulic seal kits.

hydraulic seal kits.Furthermore, the installation process of metal stakes is straightforward and hassle-free. They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort

They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary.

metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary.

They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort

They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary.

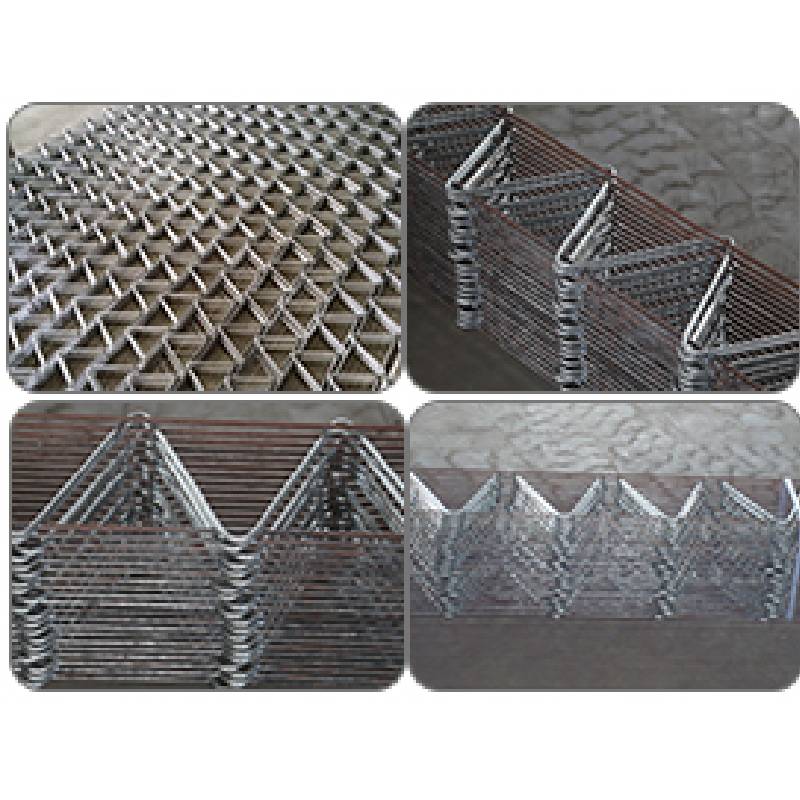

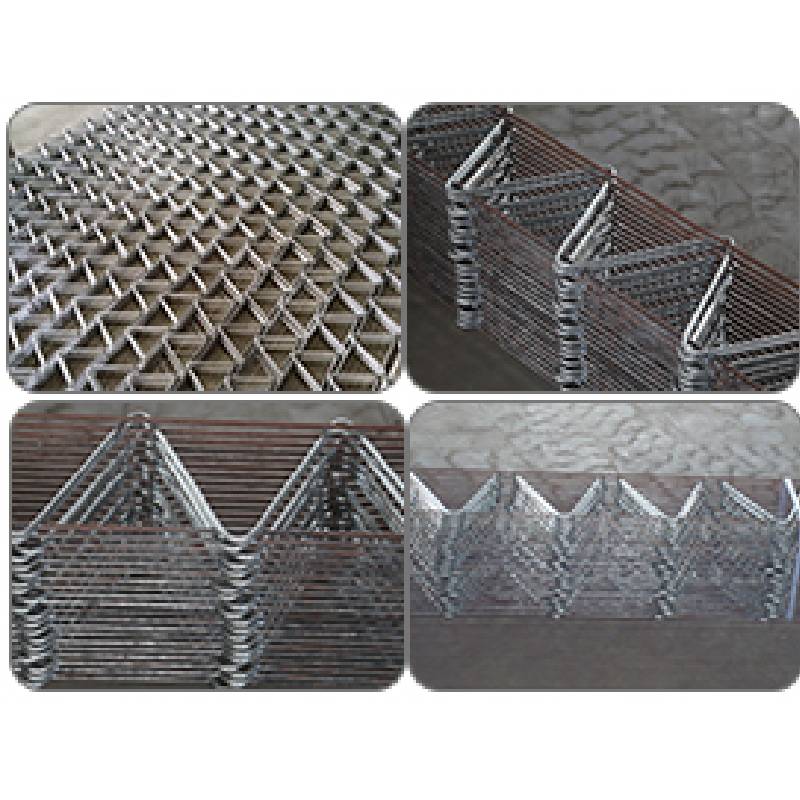

metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary.Ties, in this analogy, are the unsung heroes that bind everything together tiger cavity wall ties. In construction, they are the steel rods that fortify the wall, allowing it to withstand pressure and shift without crumbling. In ecology, they represent the invisible connections—predator-prey relationships, symbiotic interactions, and nutrient cycles—that tie all life forms together in a complex web of interdependence.

tiger cavity wall ties. In construction, they are the steel rods that fortify the wall, allowing it to withstand pressure and shift without crumbling. In ecology, they represent the invisible connections—predator-prey relationships, symbiotic interactions, and nutrient cycles—that tie all life forms together in a complex web of interdependence.

tiger cavity wall ties. In construction, they are the steel rods that fortify the wall, allowing it to withstand pressure and shift without crumbling. In ecology, they represent the invisible connections—predator-prey relationships, symbiotic interactions, and nutrient cycles—that tie all life forms together in a complex web of interdependence.

tiger cavity wall ties. In construction, they are the steel rods that fortify the wall, allowing it to withstand pressure and shift without crumbling. In ecology, they represent the invisible connections—predator-prey relationships, symbiotic interactions, and nutrient cycles—that tie all life forms together in a complex web of interdependence.In addition to stress and deflection calculations, engineers must also consider other factors that can affect the performance of the compression spring

compression spring design calculations pdf. These factors include the pitch of the coils, the end configurations of the spring, and any additional forces or moments that may be applied to the spring during operation. By accounting for these factors in the design calculations, engineers can optimize the performance of the spring and ensure that it will meet the requirements of the application.

compression spring design calculations pdf. These factors include the pitch of the coils, the end configurations of the spring, and any additional forces or moments that may be applied to the spring during operation. By accounting for these factors in the design calculations, engineers can optimize the performance of the spring and ensure that it will meet the requirements of the application.