Current location:Home > oil seal factory >

oil seal factory

2025-08-15 17:24

2025-08-15 17:13

...

2025-08-15 17:03

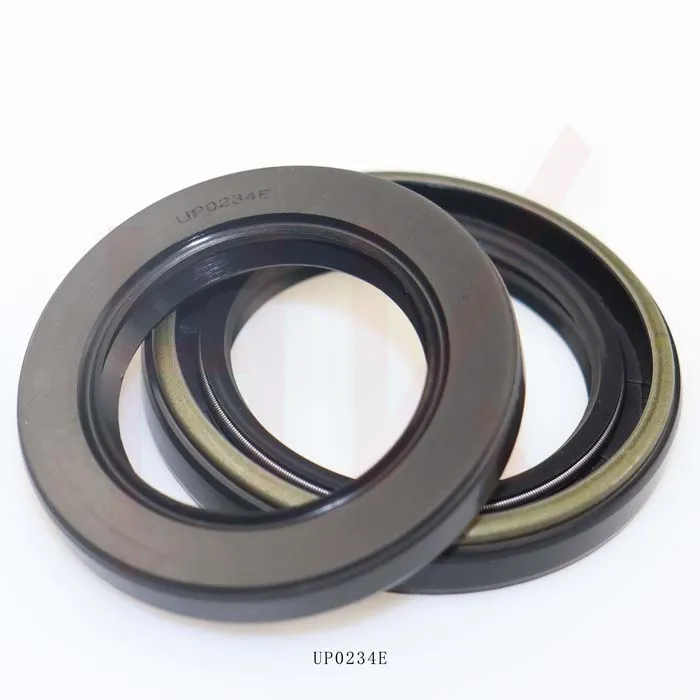

High pressure shaft seals are typically made from high-quality materials such as rubber, silicone, or metal, depending on the specific requirements of the application. These materials are carefully selected to ensure maximum durability and resistance to wear and tear, even in the harshest operating conditions

high pressure shaft seals.

high pressure shaft seals.

...

2025-08-15 16:57

2025-08-15 16:41

...

2025-08-15 16:14

2025-08-15 15:55

2025-08-15 15:37

2025-08-15 15:19

2025-08-15 15:08

Latest articles

To ensure that wheel bearing grease seals are functioning properly, it is important to inspect them regularly for any signs of wear or damage. The seals should be free of cracks, tears, or deformities that could allow grease to leak out or contaminants to enter the bearings

wheel bearing grease seal. If any issues are detected, the seals should be replaced promptly to prevent further damage to the bearings.

wheel bearing grease seal. If any issues are detected, the seals should be replaced promptly to prevent further damage to the bearings.

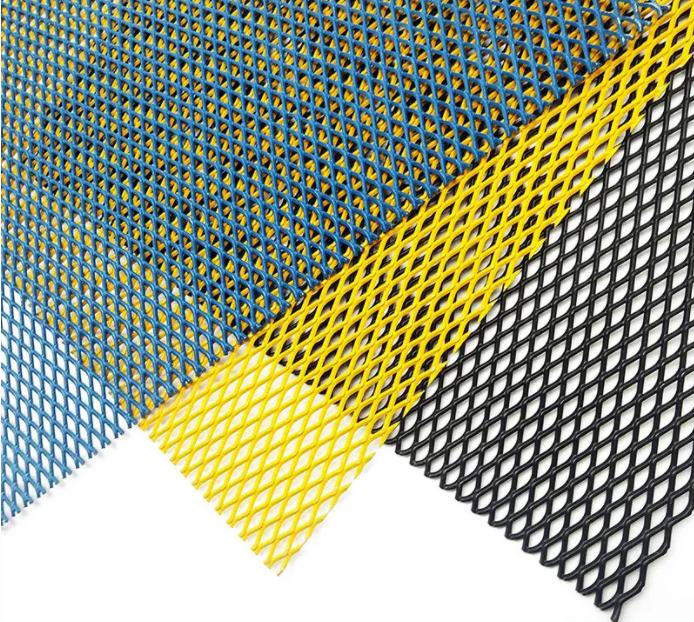

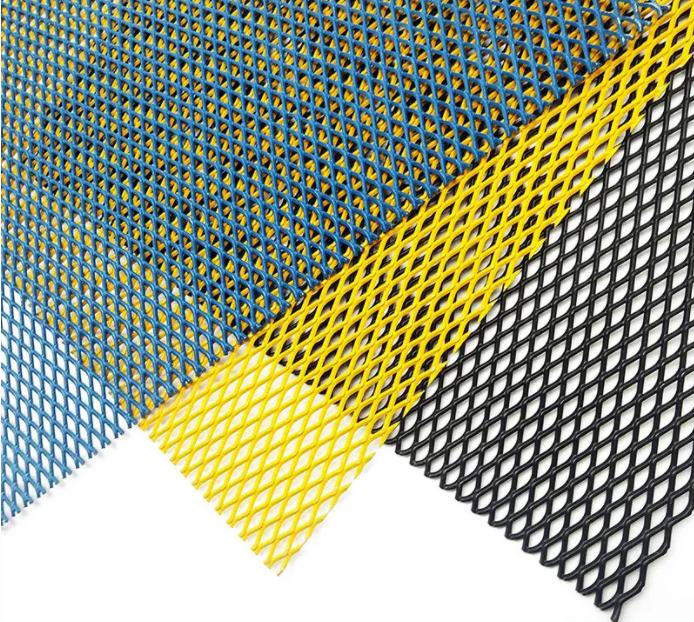

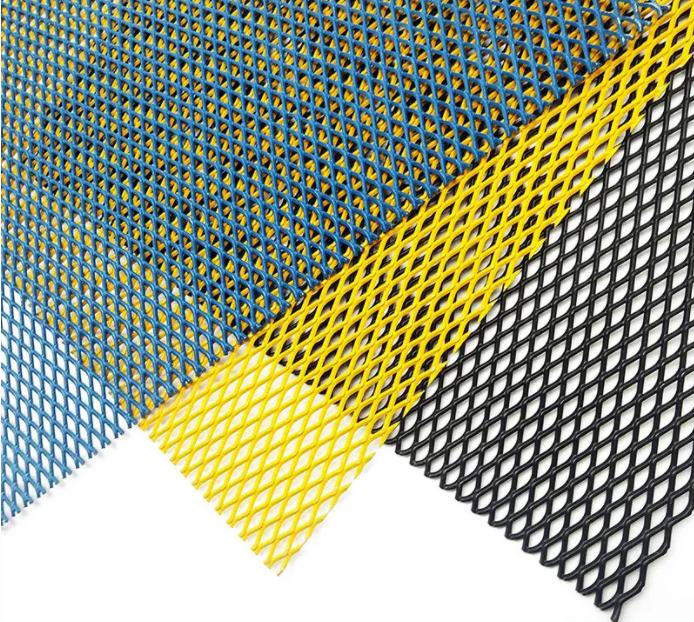

Installation costs should also be factored in. Professional installation can add a considerable amount to the total cost, but it ensures a properly installed and secure fence. DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools

DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools black cyclone fence cost. Moreover, complex installations, like those with slopes or obstacles, may incur additional labor charges.

black cyclone fence cost. Moreover, complex installations, like those with slopes or obstacles, may incur additional labor charges.

DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools

DIY installation can save money, but it requires time, effort, and the right tools DIY installation can save money, but it requires time, effort, and the right tools black cyclone fence cost. Moreover, complex installations, like those with slopes or obstacles, may incur additional labor charges.

black cyclone fence cost. Moreover, complex installations, like those with slopes or obstacles, may incur additional labor charges.Fatigue resistance is another critical aspect of the 1x19 wire rope. The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading

The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading 1x19 wire rope. This makes it ideal for dynamic applications where the rope undergoes repeated loading and unloading.

1x19 wire rope. This makes it ideal for dynamic applications where the rope undergoes repeated loading and unloading.

The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading

The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading The closely packed 19 wires distribute stress evenly, reducing the risk of premature failure due to cyclic loading 1x19 wire rope. This makes it ideal for dynamic applications where the rope undergoes repeated loading and unloading.

1x19 wire rope. This makes it ideal for dynamic applications where the rope undergoes repeated loading and unloading.