Current location:Home > 22 40 7 oil seal >

22 40 7 oil seal

2025-08-15 03:02

Another benefit of PU oil seals is their resistance to a wide range of operating conditions. They can withstand high temperatures, high pressures, and harsh chemical environments without losing their sealing properties. This makes them ideal for use in demanding applications where other seals may fail.

...

2025-08-15 02:48

2025-08-15 02:47

2025-08-15 02:45

2. Nitrile (Buna-N) Known for its compatibility with a broad range of oils and hydrocarbons, nitrile is a popular choice for seals in hydraulic systems. It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications

It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications hydraulic cylinder seal kit material.

hydraulic cylinder seal kit material.

It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications

It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications It offers good abrasion resistance and performs well at moderate temperatures, making it ideal for many industrial applications hydraulic cylinder seal kit material.

hydraulic cylinder seal kit material.

...

2025-08-15 02:24

2025-08-15 02:18

2025-08-15 02:14

Moreover, custom made oil seals can be manufactured from a variety of materials to suit the specific needs of the application. Whether it is for high-temperature environments, high-pressure systems, or corrosive chemicals, custom-made seals can be designed with the appropriate material to withstand the demands of the operating conditions. This not only extends the durability of the seals but also enhances the overall efficiency and reliability of the equipment.

...

2025-08-15 01:42

In addition to protecting the machinery from external contaminants, shaft dust seals also help to retain lubricants and fluids within the system. This is crucial for ensuring smooth operation and reducing friction between moving parts

shaft dust seal. Without a proper seal in place, lubricants can leak out, leading to increased wear and potential breakdowns. By maintaining a tight seal around the shaft, dust seals help to preserve the integrity of the lubrication system and promote optimal performance.

shaft dust seal. Without a proper seal in place, lubricants can leak out, leading to increased wear and potential breakdowns. By maintaining a tight seal around the shaft, dust seals help to preserve the integrity of the lubrication system and promote optimal performance.

...

2025-08-15 01:28

One of the primary characteristics of high temperature oil seals is their ability to maintain flexibility and resilience at elevated temperatures. Traditional rubber seals may become brittle and lose their sealing capabilities when exposed to heat. In contrast, high temperature oil seals retain their mechanical properties, ensuring that they continue to perform their sealing function effectively even in harsh conditions. Typically, these seals can withstand temperatures ranging from 150°C to over 300°C, depending on the specific material used.

high temperature oil seal

...

2025-08-15 01:12

Latest articles

Regular monitoring and changing of pump seal oil is necessary to maintain its effectiveness pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.Oil seals come in various designs depending on the specific requirements of the machinery. The 20x30x7 oil seal, for example, is a standard radial shaft seal that is installed along the shaft to prevent oil from leaking out or contaminants from entering the machinery. This type of seal is commonly used in engines, gearboxes, and other rotating equipment where the sealing of fluids is essential.

In addition to its structural benefits, welded reinforcing mesh also provides environmental benefits

welded reinforcing mesh. By using recycled steel in the manufacturing process, this mesh helps reduce the demand for raw materials and energy. This not only conserves natural resources but also reduces carbon emissions and waste. As sustainability becomes a growing concern in the construction industry, welded reinforcing mesh offers a greener alternative for builders and developers.

welded reinforcing mesh. By using recycled steel in the manufacturing process, this mesh helps reduce the demand for raw materials and energy. This not only conserves natural resources but also reduces carbon emissions and waste. As sustainability becomes a growing concern in the construction industry, welded reinforcing mesh offers a greener alternative for builders and developers.

Another advantage of black welded wire fencing is its versatility

black welded wire fencing. This type of fencing can be used in a variety of settings, including residential yards, commercial properties, agricultural land, and more. The sleek black color of the fencing can complement a wide range of architectural styles and landscaping designs, making it a popular choice for property owners looking to enhance the aesthetic appeal of their property.

black welded wire fencing. This type of fencing can be used in a variety of settings, including residential yards, commercial properties, agricultural land, and more. The sleek black color of the fencing can complement a wide range of architectural styles and landscaping designs, making it a popular choice for property owners looking to enhance the aesthetic appeal of their property.

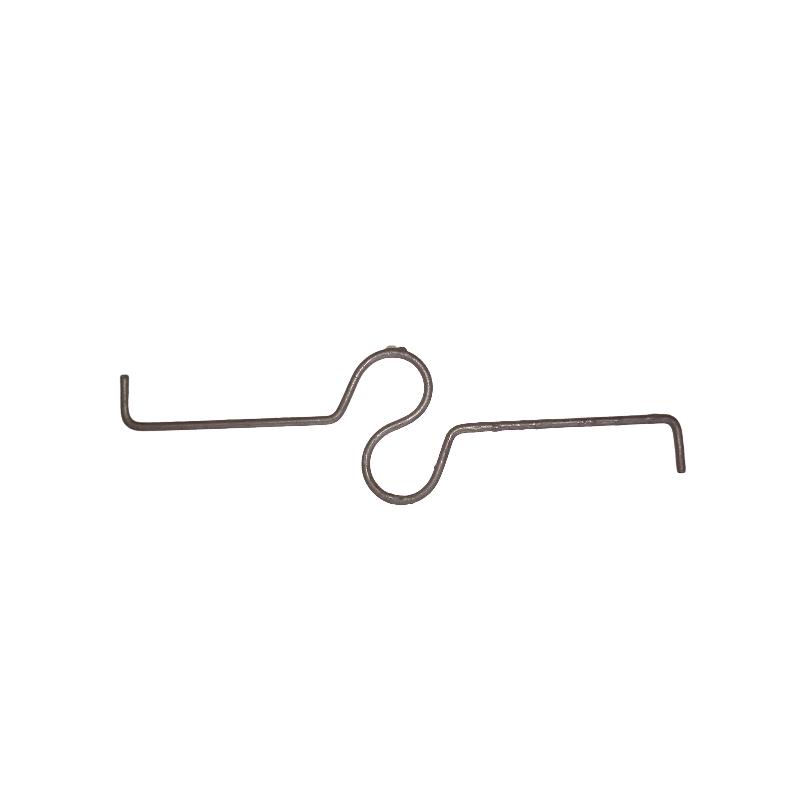

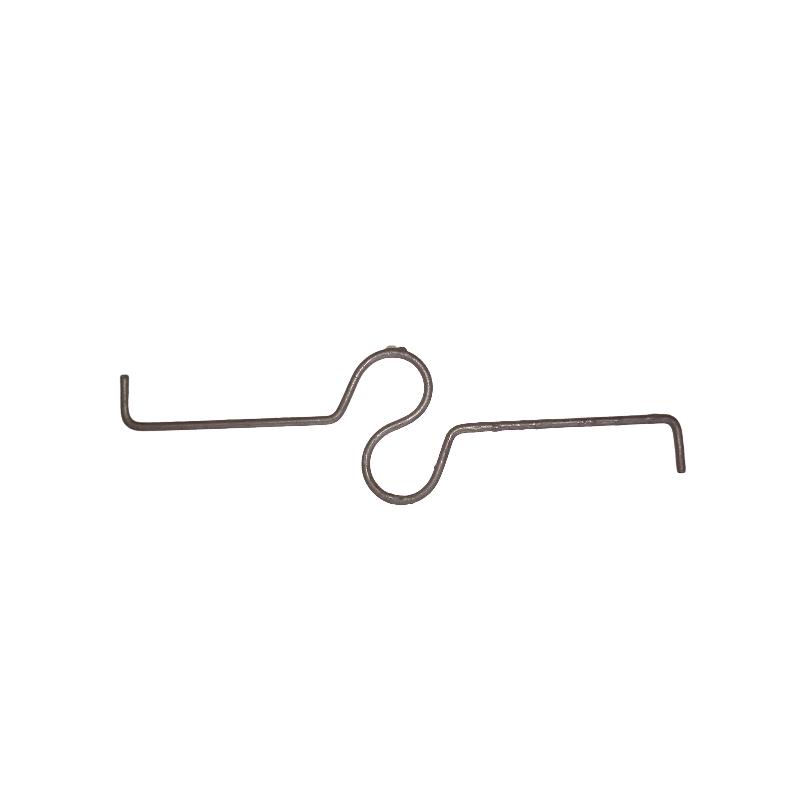

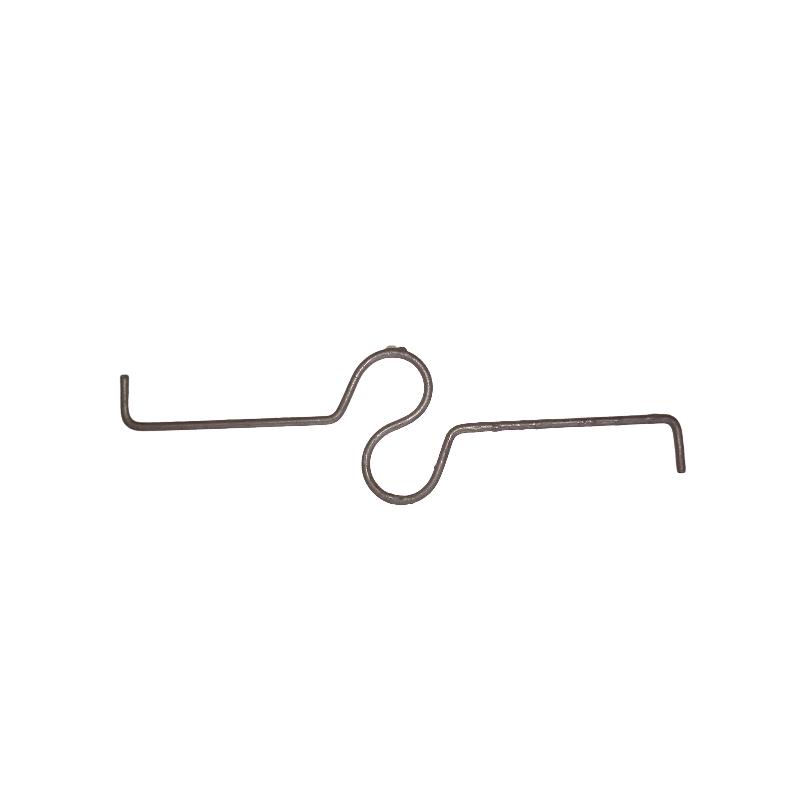

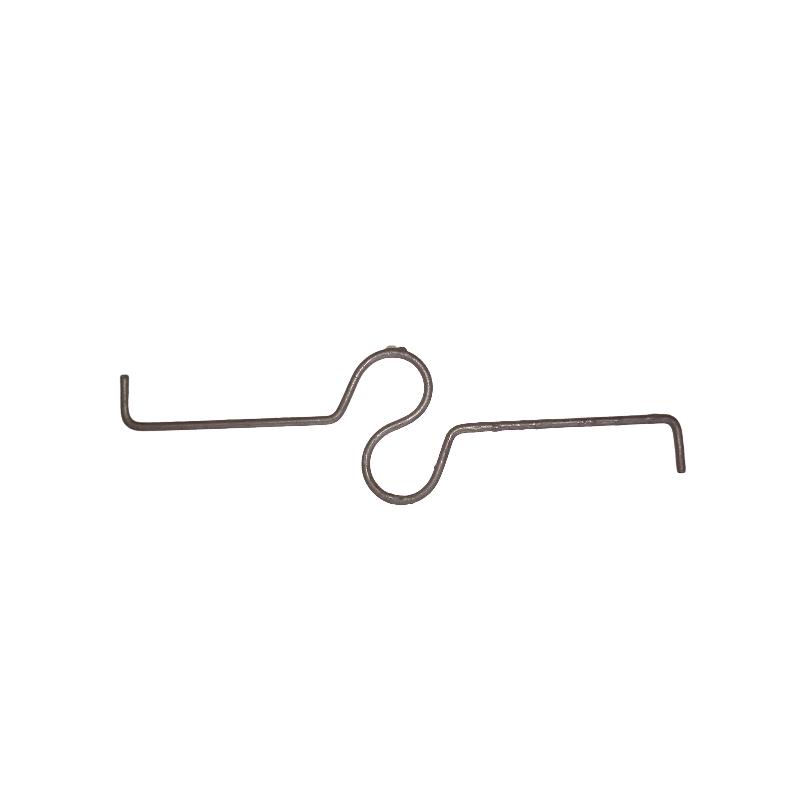

The primary function of wall ties is to transfer lateral loads, such as wind pressure, from one leaf of the wall to the other, maintaining the overall stability of the structure. They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.