Current location:Home > Hebei Hankai double wiper seal >

Hebei Hankai double wiper seal

2025-08-16 04:37

2025-08-16 04:35

Moreover, dust lip seals contribute to overall system cleanliness, which is crucial in industries where contamination control is vital, such as food processing, pharmaceuticals, and semiconductor manufacturing. They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs dust lip seal.

dust lip seal.

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs dust lip seal.

dust lip seal.

...

2025-08-16 04:20

...

2025-08-16 04:10

2025-08-16 03:28

2025-08-16 03:18

2025-08-16 03:00

2025-08-16 02:23

2025-08-16 02:08

2025-08-16 02:08

Latest articles

Regular maintenance and inspection of oil seals are essential to ensure optimal performance and prevent potential leaks. Oil seals should be checked for wear and tear, cracks, or other signs of damage that could compromise their effectiveness. Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.Seal replacement is a delicate process. New seals must fit precisely, with proper installation techniques to prevent damage during insertion. Incorrect installation can lead to premature failure, so following manufacturer guidelines is vital. For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation

For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation hydraulic cylinder seal repair.

hydraulic cylinder seal repair.

For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation

For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation For instance, rod seals often require a specific orientation, while piston seals may need lubrication before installation hydraulic cylinder seal repair.

hydraulic cylinder seal repair.Choosing the right hydraulic cylinder oil seal kit depends on several factors, including the type of fluid used, operating pressure, temperature, and the specific application hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.

hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.

hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.

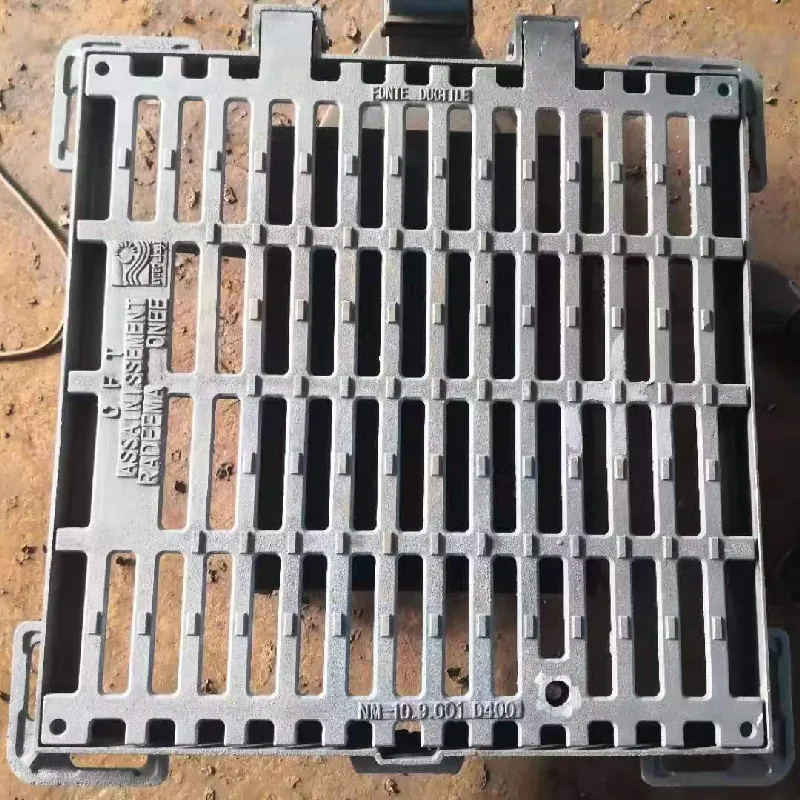

hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.Another significant advantage of ductile iron covers and frames is their resistance to corrosion. Urban environments expose infrastructure to various corrosive elements, including chemicals from roadways, saline environments, and environmental pollutants. Ductile iron can be coated with protective finishes, such as asphalt or epoxy, to further enhance its corrosion resistance. This quality extends the life of the product substantially, reducing the need for frequent repairs or replacements and thereby resulting in cost savings for municipalities and contractors.

ductile iron cover and frame