Current location:Home > Hebei Hankai oil seal for pump >

Hebei Hankai oil seal for pump

2025-08-14 19:42

2025-08-14 19:24

2025-08-14 19:15

2025-08-14 19:09

2025-08-14 18:52

2025-08-14 18:47

2025-08-14 18:16

2025-08-14 18:15

2025-08-14 17:23

2025-08-14 17:11

Latest articles

To address these challenges, high pressure shaft seals are typically made from materials such as high-strength metals, ceramics, or specially formulated elastomers that can withstand high pressures and temperatures

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

One of the key features of CFW oil seals is their durability and resistance to wear and tear. Made from high-quality materials such as rubber, silicone, or polytetrafluoroethylene (PTFE), these seals are able to withstand extreme conditions without compromising their sealing capabilities. This makes them ideal for use in machinery and equipment that operate under demanding conditions.

The sealing effectiveness of a high pressure lip seal is influenced by several factors, including the choice of elastomer, the design of the lip, the quality of the shaft surface, and the operating temperature. The elastomer must be resistant to the specific fluid or gas being sealed, while the lip design should allow for minimal friction and wear. The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

high pressure lip seal.

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

high pressure lip seal.In addition to the convenience of having all the necessary seals in one kit, using a 3-inch hydraulic cylinder seal kit can also help ensure the proper functioning of your equipment

3 inch hydraulic cylinder seal kit. Worn-out seals can lead to leaks, loss of pressure, and decreased performance, all of which can impact the efficiency and safety of your machinery.

3 inch hydraulic cylinder seal kit. Worn-out seals can lead to leaks, loss of pressure, and decreased performance, all of which can impact the efficiency and safety of your machinery.

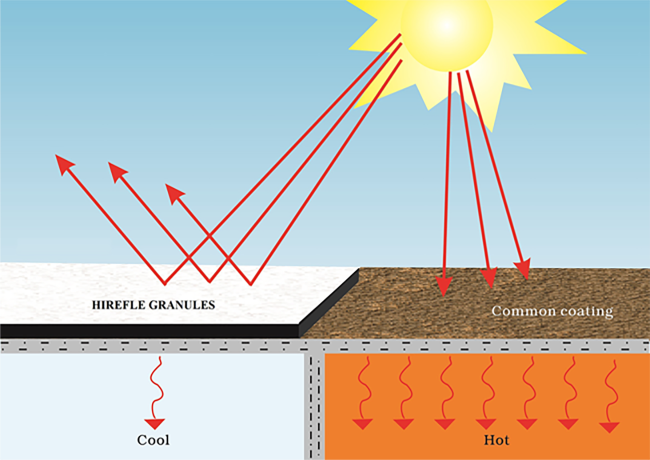

Another significant advantage of rubberized shingles is their ease of installation. They are lightweight compared to traditional roofing materials, making them easier to handle and install. This not only simplifies the installation process but can also reduce labor costs. Furthermore, rubberized shingles can be installed over existing roofs without the need for extensive demolition, allowing homeowners to save time and money during the roofing process.

rubberized shingles