Current location:Home > Hebei Hankai metric shaft seals >

Hebei Hankai metric shaft seals

2025-08-16 05:22

2025-08-16 04:25

2025-08-16 04:21

2025-08-16 04:12

2025-08-16 04:01

2025-08-16 03:34

2025-08-16 03:17

2025-08-16 03:09

2025-08-16 02:59

2025-08-16 02:48

Latest articles

From a maintenance perspective, the integrity of the outer hub oil seal is paramount. Routine checks during tire rotations or when performing brake services should include an inspection of these seals for signs of cracking, brittleness, or visible leaks. If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line outer hub oil seal.

outer hub oil seal.

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line outer hub oil seal.

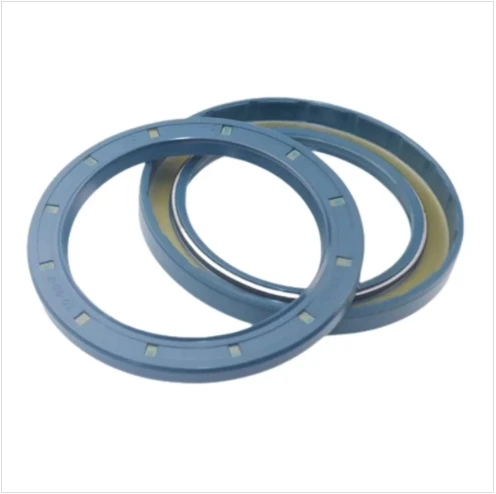

outer hub oil seal.Combi oil seals find extensive use in a variety of industries, including automotive, aerospace, mining, and power generation combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.

combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.

combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.

combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.In addition to protecting the bearing from external contaminants, dust seals also help to retain lubricants within the bearing housing. This is important because lubricants help to reduce friction and heat generation within the bearing, which can lead to wear and eventual failure. By keeping the lubricant in place, dust seals help to ensure that the bearing operates smoothly and efficiently

bearing dust seal.

bearing dust seal.