Current location:Home > hydraulic seal >

hydraulic seal

2025-08-15 04:44

2025-08-15 04:35

Once the old seal is removed, clean the area around the hub thoroughly to remove any dirt or debris

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

...

2025-08-15 04:33

2025-08-15 04:32

2025-08-15 04:22

2025-08-15 04:06

2025-08-15 03:05

2025-08-15 03:01

...

2025-08-15 02:41

The design of hub dust seals varies depending on the application and environmental conditions hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

...

2025-08-15 02:24

Latest articles

The importance of rotary oil seals becomes evident when considering the potential consequences of oil leakage. Not only can leaks result in loss of lubricant, leading to increased wear and tear on moving parts, but they also pose environmental hazards and add to maintenance costs. In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role

In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role rotary oil seals.

rotary oil seals.

In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role

In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role In high-performance applications such as automotive engines or industrial machinery, the failure of an oil seal can lead to catastrophic system failure, underscoring the critical nature of their role rotary oil seals.

rotary oil seals.Another benefit of small welded wire mesh is its versatility. The mesh can be cut and shaped to fit any size or shape, making it suitable for a wide range of applications. For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures

For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security.

small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security.

For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures

For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security.

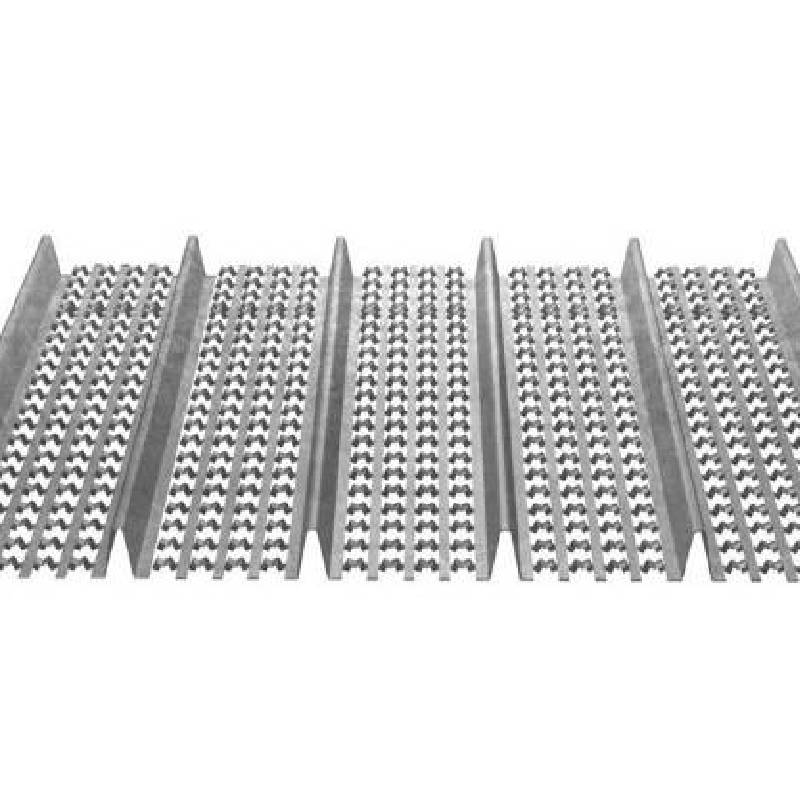

small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security.In addition to providing structural support, welded wire reinforcement can also improve the overall durability of the concrete. The steel wires are resistant to corrosion and provide an extra layer of protection against environmental factors such as moisture and temperature fluctuations

welded wire reinforcement for concrete. This can help extend the lifespan of the concrete and reduce the need for maintenance and repairs in the long run.

welded wire reinforcement for concrete. This can help extend the lifespan of the concrete and reduce the need for maintenance and repairs in the long run.

In the world of crafts and DIY projects, flexible iron wire is a popular choice for creating everything from jewelry and sculptures to decorations and household items. Its strength and durability make it a reliable choice for projects that require a sturdy material, while its flexibility allows for creative and unique designs that can be easily achieved.