Current location:Home > Hebei Hankai hub oil seal >

Hebei Hankai hub oil seal

2025-08-15 22:23

2025-08-15 22:15

Another important function of the wheel oil seal is to protect the wheel bearings from external contaminants. The bearings are responsible for allowing the wheel to rotate smoothly, and any dirt or water that seeps in can cause them to wear out quickly

wheel oil seal. By sealing off the bearings from the outside environment, the oil seal helps to extend the lifespan of the wheel assembly and ensure optimal performance.

wheel oil seal. By sealing off the bearings from the outside environment, the oil seal helps to extend the lifespan of the wheel assembly and ensure optimal performance.

...

2025-08-15 22:04

2025-08-15 21:54

2025-08-15 21:27

2025-08-15 21:04

The mechanical seal is a more complex type, consisting of two precision-machined faces that slide against each other to create a seal. This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences

This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences hydraulic oil seal types. Mechanical seals require careful installation and maintenance but offer superior performance in challenging environments.

hydraulic oil seal types. Mechanical seals require careful installation and maintenance but offer superior performance in challenging environments.

This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences

This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences This type is commonly used in pumps and other equipment where there is a high risk of leakage due to pressure differences hydraulic oil seal types. Mechanical seals require careful installation and maintenance but offer superior performance in challenging environments.

hydraulic oil seal types. Mechanical seals require careful installation and maintenance but offer superior performance in challenging environments.

...

2025-08-15 20:59

The 14x24x6 oil seal finds applications in a wide range of industries, from automotive to industrial machinery

. Here are some notable areas...

2025-08-15 20:55

2025-08-15 20:50

2025-08-15 20:32

Latest articles

Single lip oil seals are commonly used in a wide range of machinery and automotive applications single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.Regular maintenance of gearbox seals is crucial to ensure their proper functioning and to prevent any potential problems. Over time, gearbox seals can become worn out or damaged due to prolonged use, exposure to harsh environmental conditions, or improper installation. It is important to inspect the seals regularly for any signs of wear, tears, or leaks and replace them as needed to avoid any potential issues.

There are several types of seals used in gearboxes, each with its own unique design and function. O-rings, for example, are commonly used to provide a tight seal between two moving parts. They are made of a resilient material and can withstand high pressures and temperatures. Another type of seal is the lip seal, which consists of a flexible rubber or plastic lip that creates a seal against a rotating shaft. Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations

Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations gearbox seals.

gearbox seals.

Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations

Lip seals are often used in applications where the shaft is subject to high speeds or vibrations Lip seals are often used in applications where the shaft is subject to high speeds or vibrations gearbox seals.

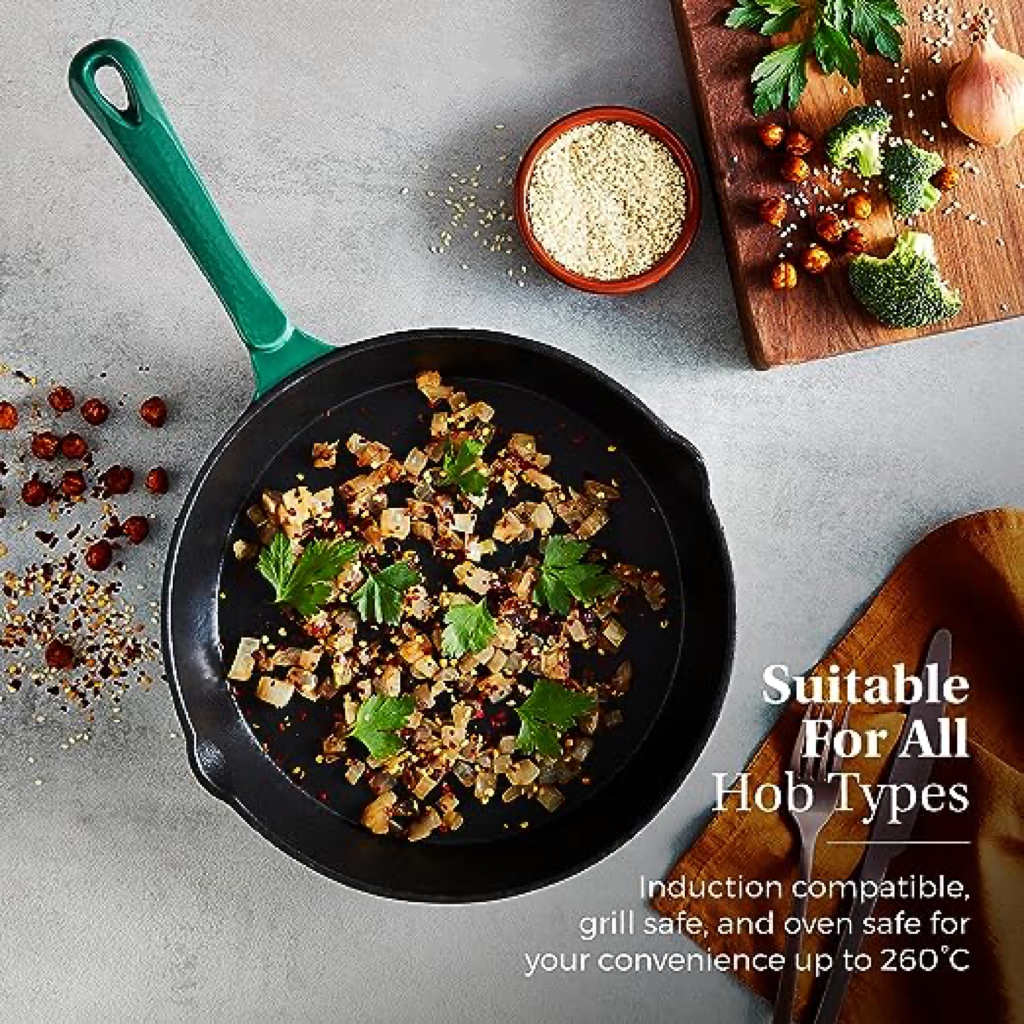

gearbox seals.Enamel cook sets come in a rainbow of colors, adding a touch of vibrancy to any kitchen decor. From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.