Current location:Home > high pressure oil seals >

high pressure oil seals

One of the key features of the 22% 40% 7% oil seal is its ability to maintain a secure seal even under extreme pressure and temperature conditions. This makes it suitable for use in industrial equipment, automotive engines, and hydraulic systems where reliable sealing is critical for optimal performance. The superior sealing capabilities of the 22% 40% 7% oil seal help to prevent leaks and ensure consistent lubrication of moving parts.

...

2025-08-15 01:59

2025-08-15 01:58

2025-08-15 01:41

2025-08-15 01:38

2025-08-15 01:37

2025-08-15 01:26

2025-08-15 01:02

2025-08-15 00:12

2025-08-15 00:09

2025-08-14 23:55

Latest articles

In addition to withstanding high temperatures, these seals must also be resistant to corrosion and wear. They are often exposed to harsh chemicals or abrasive materials, so they need to be able to hold up under these conditions without deteriorating over time

high temperature shaft seals.

high temperature shaft seals.

One of the primary benefits of shaft dust seals is their ability to protect the machinery's internal components from abrasive particles that can cause friction and wear. Dust and dirt particles can not only damage the shaft itself but also the bearings, gears, and other moving parts within the system. By keeping these contaminants out, shaft dust seals help to extend the lifespan of the machinery and reduce the frequency of maintenance and repairs.

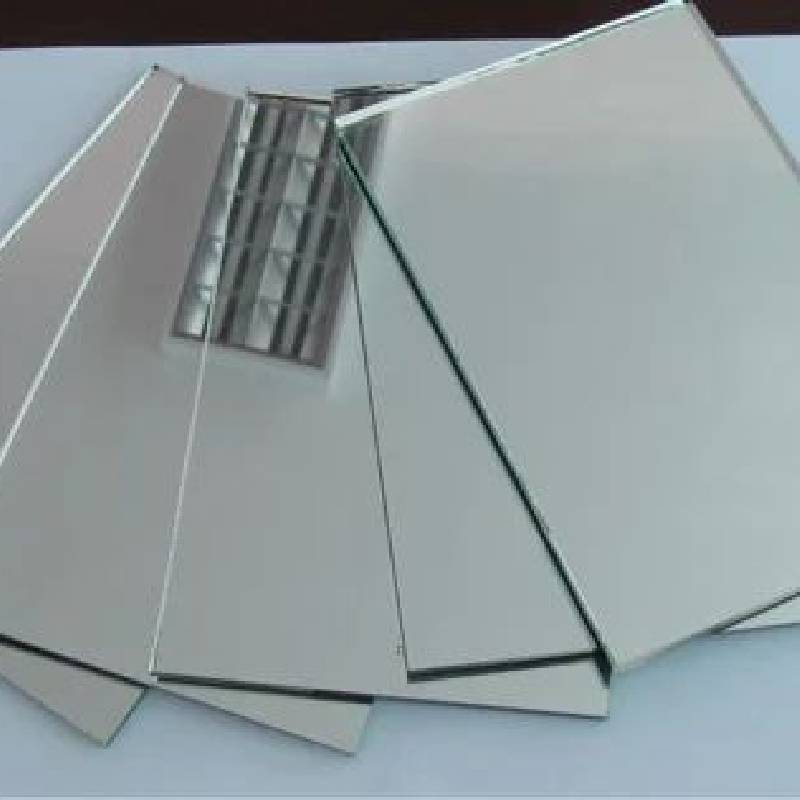

Raw material quality is another crucial factor that affects the quality of tempered glass. High-quality raw materials, such as clear, pure, and uniform glass, are essential for producing high-performance tempered glass. Contaminants, such as iron and nickel particles, can significantly reduce the glass's transparency and strength, leading to poor quality. Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass tempered glass quality.

tempered glass quality.

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass tempered glass quality.

tempered glass quality.Today, pattern glass suppliers continue to push the boundaries of design and innovation. With advancements in technology and manufacturing processes, they can produce glass that meets both aesthetic and functional demands. Whether through traditional methods or modern technologies like digital printing, suppliers are finding new ways to create stunning glass pieces that cater to various tastes and requirements.