Current location:Home > 30x42x7 oil seal >

30x42x7 oil seal

...

2025-08-14 22:30

From a maintenance perspective, the integrity of the outer hub oil seal is paramount. Routine checks during tire rotations or when performing brake services should include an inspection of these seals for signs of cracking, brittleness, or visible leaks. If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line outer hub oil seal.

outer hub oil seal.

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line

If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line If any issues are detected, prompt replacement is advised to avoid catastrophic damage further down the line outer hub oil seal.

outer hub oil seal.

...

2025-08-14 21:20

2025-08-14 21:18

2025-08-14 21:07

2025-08-14 21:04

2025-08-14 20:54

2025-08-14 20:31

2025-08-14 20:23

2025-08-14 20:16

Secondly, the expertise and reputation of the manufacturer cannot be underestimated. Look for companies with a track record of innovation and commitment to quality assurance. Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards

Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system.

hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system.

Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards

Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system.

hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system.

...

2025-08-14 19:48

Latest articles

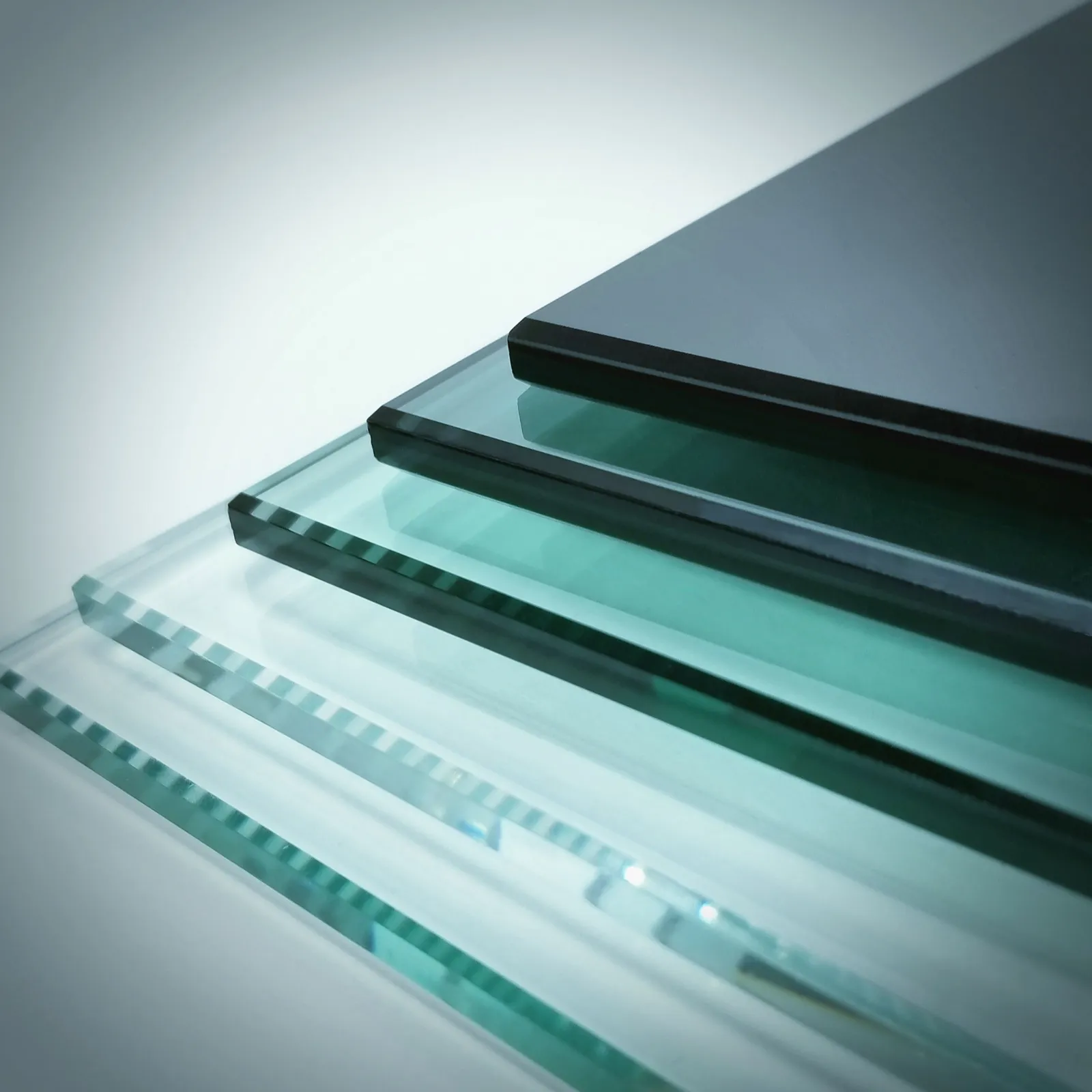

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets

Moreover, Pyrolytic Low-E glass is not just about energy savings; it also enhances indoor comfort by controlling glare and maintaining natural light transmission. It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage

It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage pyrolytic low e glass.

pyrolytic low e glass.

It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage

It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage It allows sunlight to enter the building while blocking harmful ultraviolet (UV) rays, protecting furnishings and occupants from fading and sun damage pyrolytic low e glass.

pyrolytic low e glass.