Current location:Home > Hebei Hankai hydraulic seal tool kit >

Hebei Hankai hydraulic seal tool kit

2025-08-14 19:52

2025-08-14 19:32

2025-08-14 19:11

2025-08-14 19:04

2025-08-14 19:00

2025-08-14 18:48

2025-08-14 18:34

2025-08-14 18:05

2025-08-14 17:47

2025-08-14 17:33

Latest articles

Maintenance of rotary shaft oil seals involves regular inspections for signs of wear, such as cracking, deformation, or excessive leakage rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.Once the old seal is removed, clean the area around the hub thoroughly to remove any dirt or debris

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

In addition to their role in passenger cars, hub oil seals are equally important in heavy-duty vehicles, off-road equipment, and industrial machinery where they protect critical components from harsh operating conditions hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.

hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.

hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.

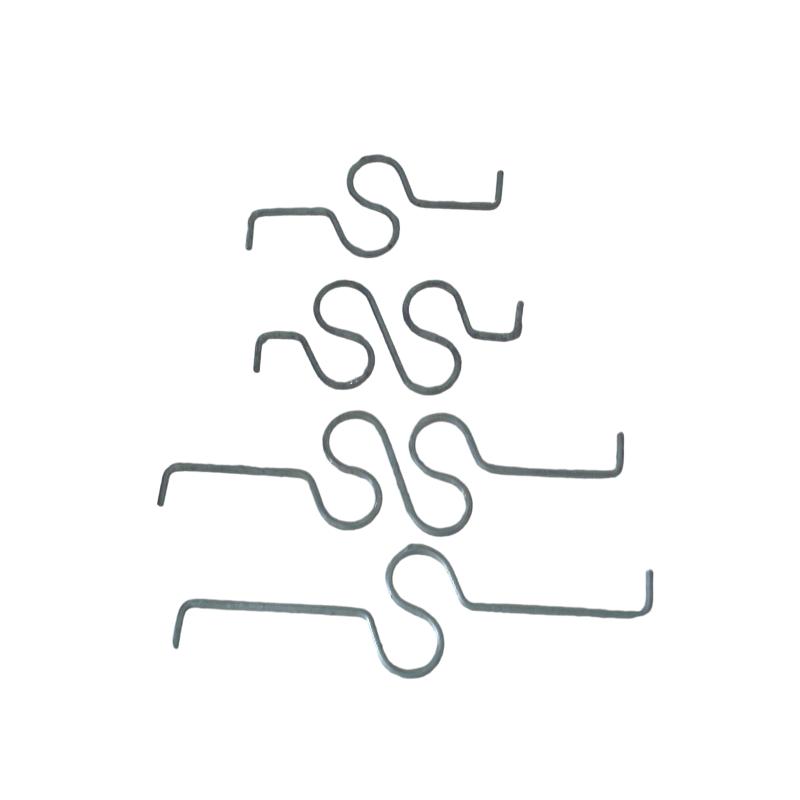

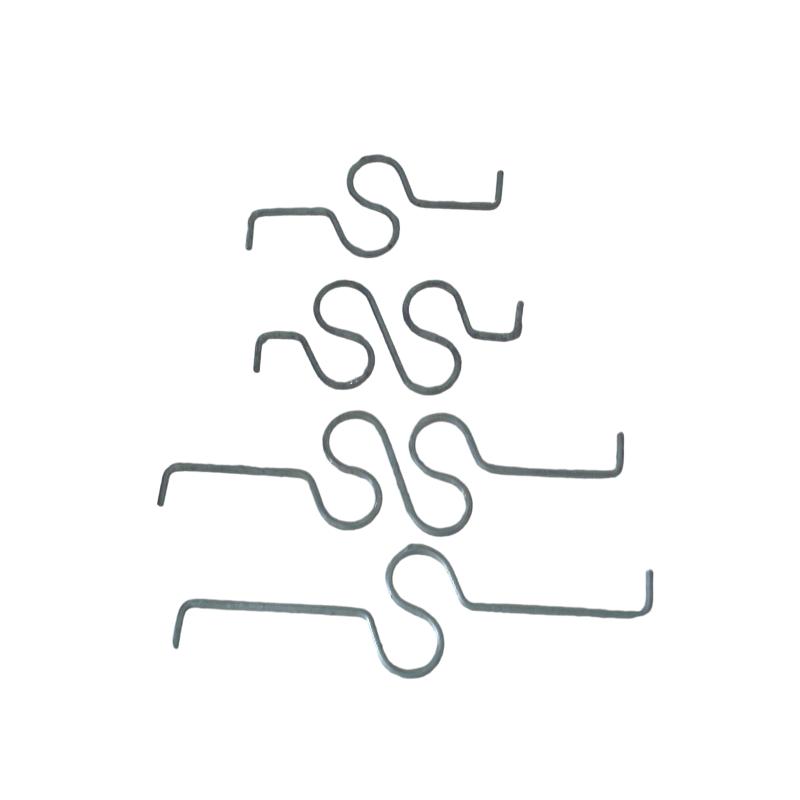

hub oil seal. Their durability and reliability make them indispensable in ensuring the smooth functioning of these systems.The design of an expansion spring is relatively simple, consisting of a coil of wire that is wound tightly together in a helical shape. When a force is applied to the ends of the spring, the coil is stretched out, causing the spring to expand. When the force is removed, the coil contracts back to its original position. The amount of force required to stretch the spring and the distance it will expand can be adjusted by changing the size and thickness of the wire, as well as the number of coils in the spring.

In addition to their durability, spiral torsion springs are also known for their versatility. They can be customized to meet the specific requirements of a particular application, including variations in size, shape, and material. This flexibility makes them a popular choice for many different industries

spiral torsion spring.

spiral torsion spring.