Current location:Home > 2 inch hydraulic cylinder seal kit >

2 inch hydraulic cylinder seal kit

2025-08-14 13:34

2025-08-14 13:23

2025-08-14 13:00

2025-08-14 12:49

2025-08-14 11:29

2025-08-14 11:28

2025-08-14 11:10

2025-08-14 11:07

2025-08-14 11:05

2025-08-14 10:58

Latest articles

In power generation, high pressure shafts play a critical role in steam turbines. Here, they are subjected to steam at extremely high pressures, converting thermal energy into kinetic energy. The rotation of the shaft drives the generator, producing electricity. Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.Regular maintenance and inspection of oil seals are essential to ensure optimal performance and prevent potential leaks. Oil seals should be checked for wear and tear, cracks, or other signs of damage that could compromise their effectiveness. Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.The 'oil' in the name denotes the seal's compatibility with oil-based lubricants. It is typically made from materials like nitrile rubber (NBR), which offers excellent resistance to oils, heat, and pressure. The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions 35x72x10 oil seal.

35x72x10 oil seal.

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions 35x72x10 oil seal.

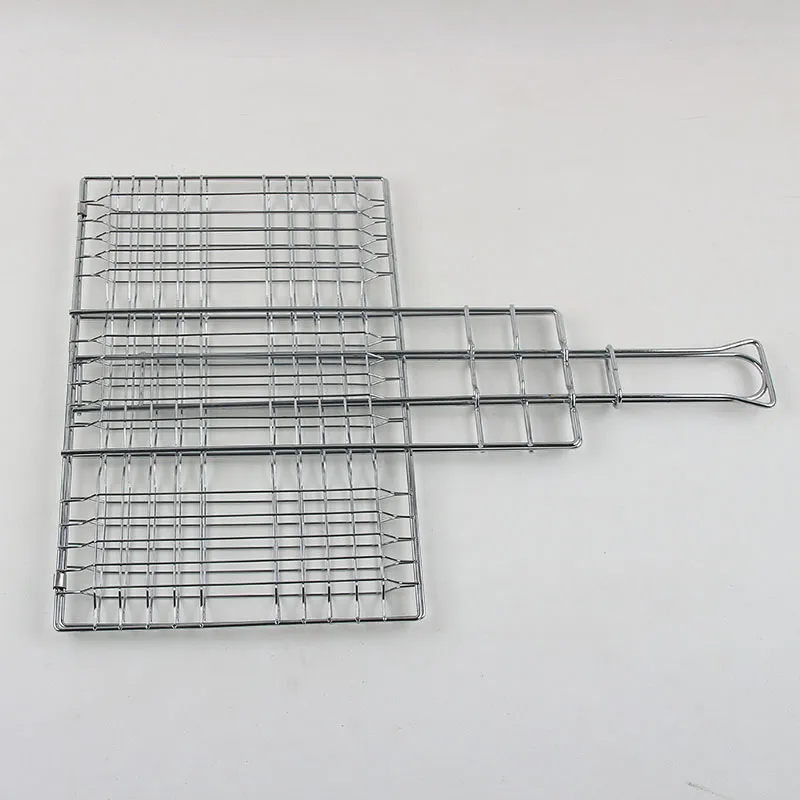

35x72x10 oil seal.Another vital aspect to consider is the design of the racks. A good dehydrator rack supplier will offer racks that are designed for optimal airflow. Efficient airflow is essential for even dehydration, as it helps remove moisture from food more effectively. Racks that are spaced appropriately can improve air circulation, leading to quicker and more uniform drying. Suppliers that prioritize this detail often have a better understanding of the dehydration process and can offer insights into enhancing your food preservation methods.

dehydrator rack supplier