Current location:Home > 25 40 7 seal >

25 40 7 seal

2025-08-16 04:00

2025-08-16 03:59

2025-08-16 03:54

2025-08-16 03:26

2025-08-16 02:40

2025-08-16 02:34

2025-08-16 02:26

2025-08-16 02:03

The use of oil seals like the 38x52x7 is paramount in preventing contamination 38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

...

2025-08-16 01:59

2025-08-16 01:48

Latest articles

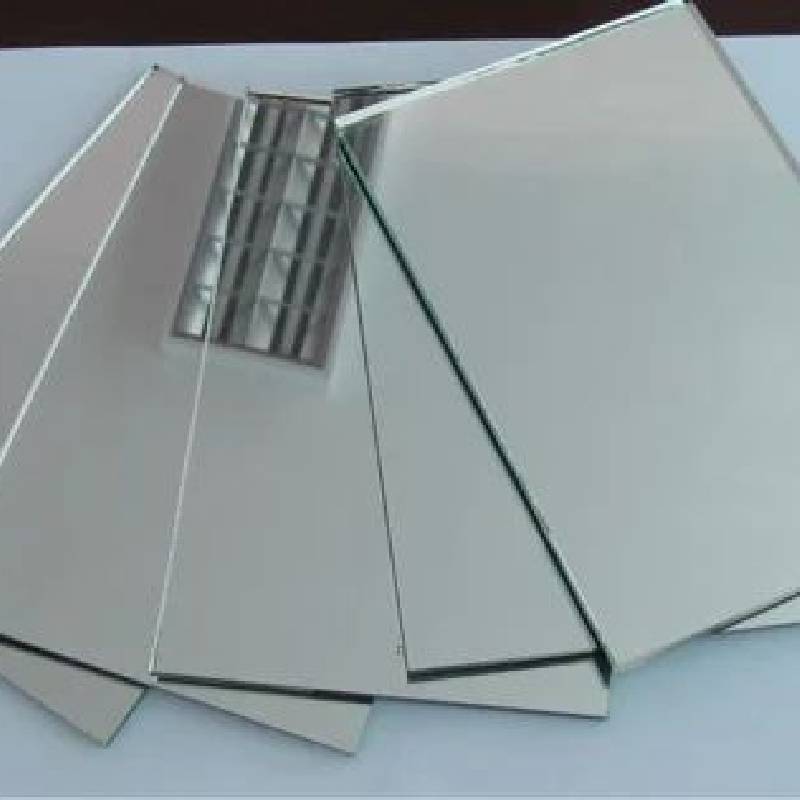

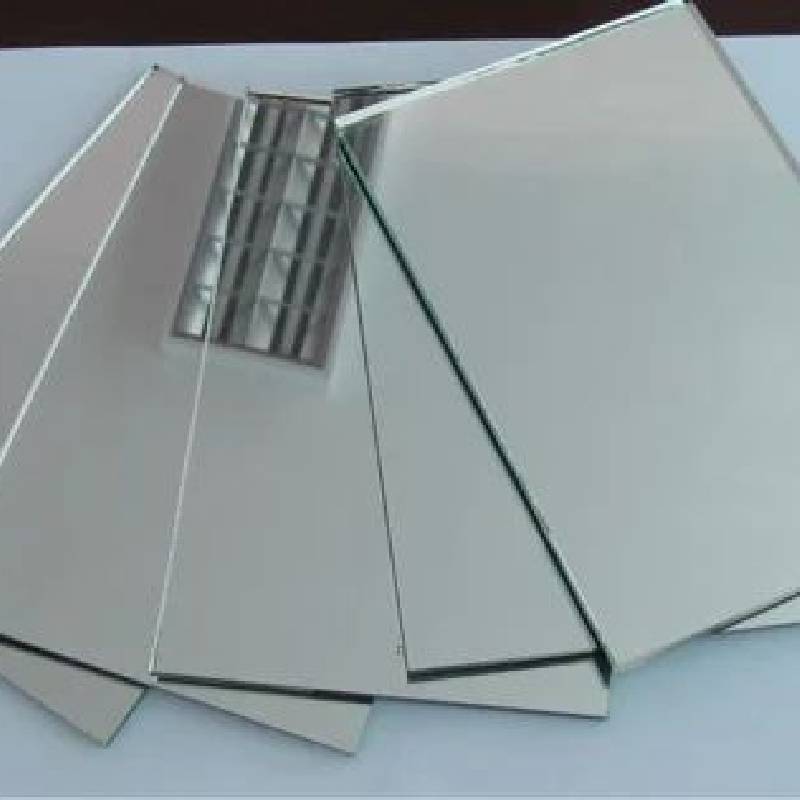

Another key feature of combi oil seals is their ease of installation and replacement

. These seals are designed to be easy to install and remove, making maintenance and repairs quick and convenient. This helps to minimize downtime and reduce overall maintenance costs for the machinery.Beyond its aesthetic appeal, the silver trim mirror serves a practical purpose. Its reflective nature amplifies light, creating an illusion of space and brightness, particularly beneficial in smaller or darker rooms. Strategically placed, it can also be used to reflect a beautiful view or to showcase a prized artwork opposite to it, thereby extending the visual delights of a room Strategically placed, it can also be used to reflect a beautiful view or to showcase a prized artwork opposite to it, thereby extending the visual delights of a roomsilver trim mirror.

Another factor that can influence the cost of mirror glass per square foot is the size of the mirrors being purchased. Larger mirrors will generally cost more per square foot than smaller mirrors, as they require more material to produce. Additionally, custom-cut mirrors may also cost more per square foot than standard sized mirrors, as they require more labor and precision to create

cost of mirror glass per square foot.

cost of mirror glass per square foot.

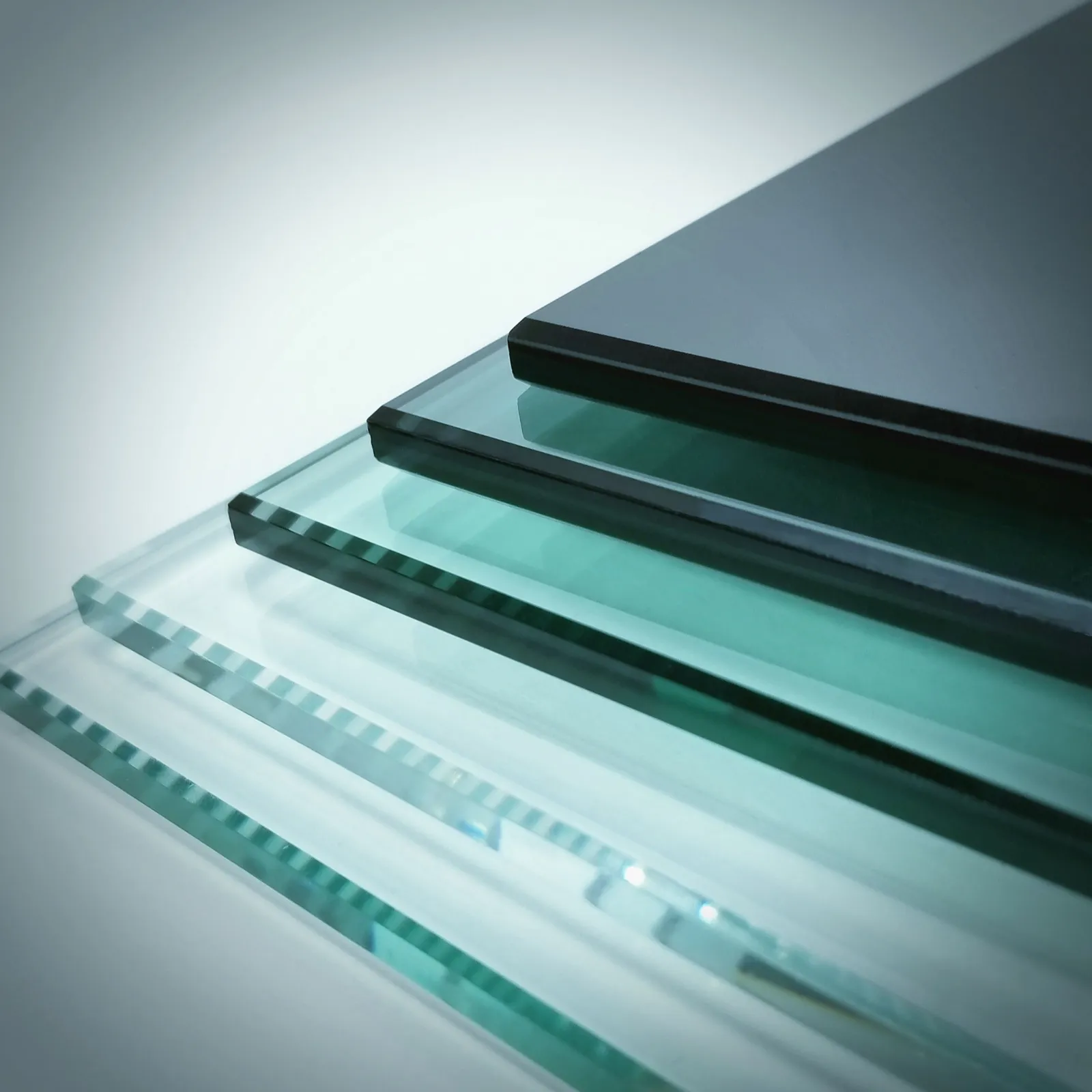

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets