2025-08-14 13:16

Current location:Home > hydraulic seal tool kit >

hydraulic seal tool kit

2025-08-14 12:26

2. Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs

Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs cross hydraulic cylinder seal kits. This is because it eliminates the need for frequent replacement of individual seals, which can be expensive and time-consuming.

cross hydraulic cylinder seal kits. This is because it eliminates the need for frequent replacement of individual seals, which can be expensive and time-consuming.

Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs

Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs Cost-effective By providing a complete set of seals for a specific cylinder size, cross hydraulic cylinder seal kits help to reduce the overall cost of maintenance and repairs cross hydraulic cylinder seal kits. This is because it eliminates the need for frequent replacement of individual seals, which can be expensive and time-consuming.

cross hydraulic cylinder seal kits. This is because it eliminates the need for frequent replacement of individual seals, which can be expensive and time-consuming.

...

2025-08-14 12:23

2025-08-14 12:21

2025-08-14 12:15

2025-08-14 11:28

2025-08-14 11:21

2025-08-14 11:07

2025-08-14 10:59

2025-08-14 10:51

Latest articles

Furthermore, wheel bearing grease seals act as a protective barrier against contaminants that can cause premature wear and damage to the bearings. Dirt, water, and other debris can easily enter the bearings if the seals are not properly maintained, leading to corrosion and friction that can compromise the wheel assembly system's efficiency and safety.

In industrial machinery, skeleton oil seals are utilized in gearboxes, pumps, and compressors

. These seals protect the internal components from environmental contaminants and ensure that the lubricants remain intact, thus reducing wear and tear on machinery. The robustness of skeleton oil seals makes them ideal for high-performance applications where reliability is paramount.Over time, the wheel bearing hub seal can wear out and become damaged, leading to leaks and potential contamination of the wheel bearings. Signs that the wheel bearing hub seal may be failing include squeaking or grinding noises coming from the wheels, uneven tire wear, and vibrations in the steering wheel.

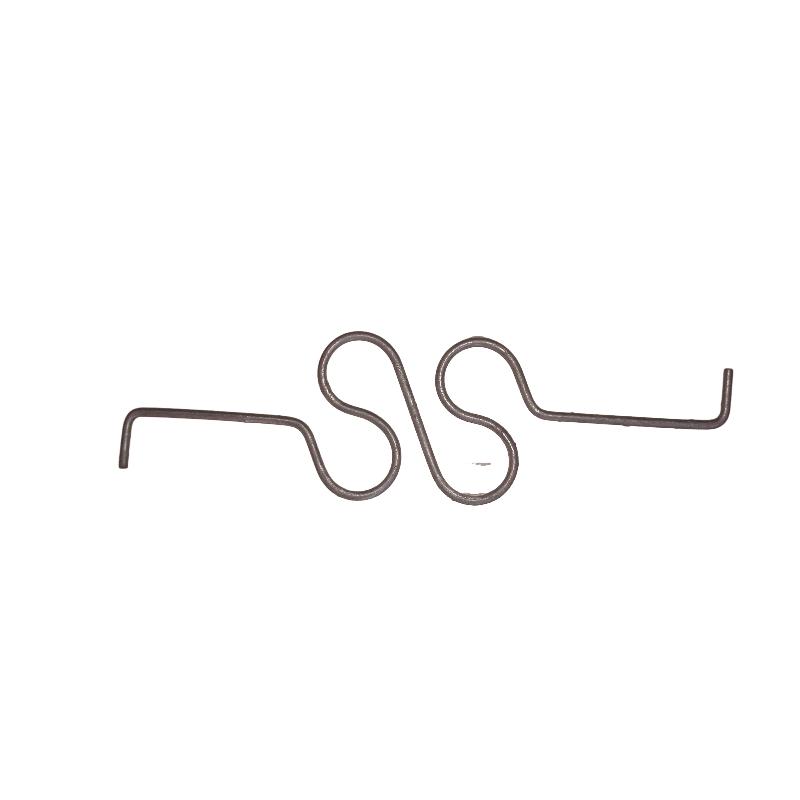

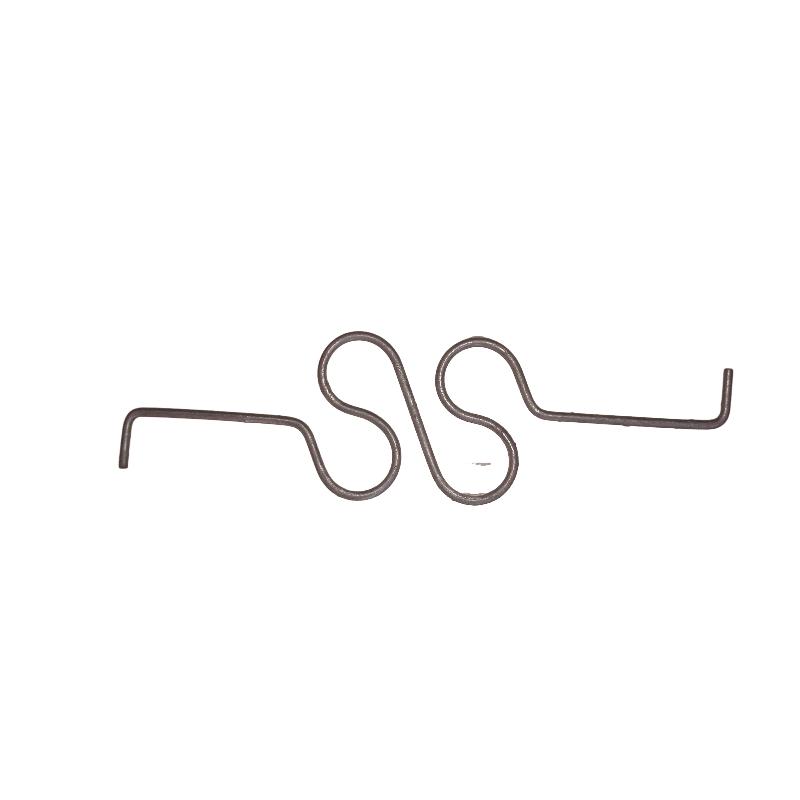

While modern construction methods have evolved significantly, the use of brick ends ties remains a popular choice for many architects and builders brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.