Current location:Home > custom made oil seals >

custom made oil seals

2025-08-15 06:26

2025-08-15 06:24

2025-08-15 06:22

2025-08-15 06:06

2025-08-15 05:50

2025-08-15 05:44

2025-08-15 05:36

2025-08-15 04:28

2025-08-15 04:09

2025-08-15 04:05

Latest articles

One of the key features of high pressure rotary shaft seals is their ability to manage heat generation. The friction between the seal and the shaft can create significant heat, which if not managed, can lead to seal failure. To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively

To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively high pressure rotary shaft seal.

high pressure rotary shaft seal.

To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively

To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively To combat this, modern seals incorporate advanced thermal management techniques and materials, such as thermally conductive fillers, to dissipate heat effectively high pressure rotary shaft seal.

high pressure rotary shaft seal.This particular oil seal is designed to accommodate a shaft diameter of 50mm while sealing against a housing with an outer diameter of 90mm, ensuring tight closure and effective sealing. The 10mm width is optimal for creating a sufficient sealing surface to prevent leakage while maintaining a low profile in installations.

50x90x10 oil seal

In addition, custom oil seals can improve the efficiency and reliability of machinery by ensuring that oil is properly contained and distributed to the necessary components. By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity

By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity custom oil seals. This can result in improved productivity, higher quality output, and overall better performance of the equipment.

custom oil seals. This can result in improved productivity, higher quality output, and overall better performance of the equipment.

By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity

By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity By preventing oil leaks, these seals help to maintain the proper lubrication levels in the system, which is essential for optimal performance and longevity custom oil seals. This can result in improved productivity, higher quality output, and overall better performance of the equipment.

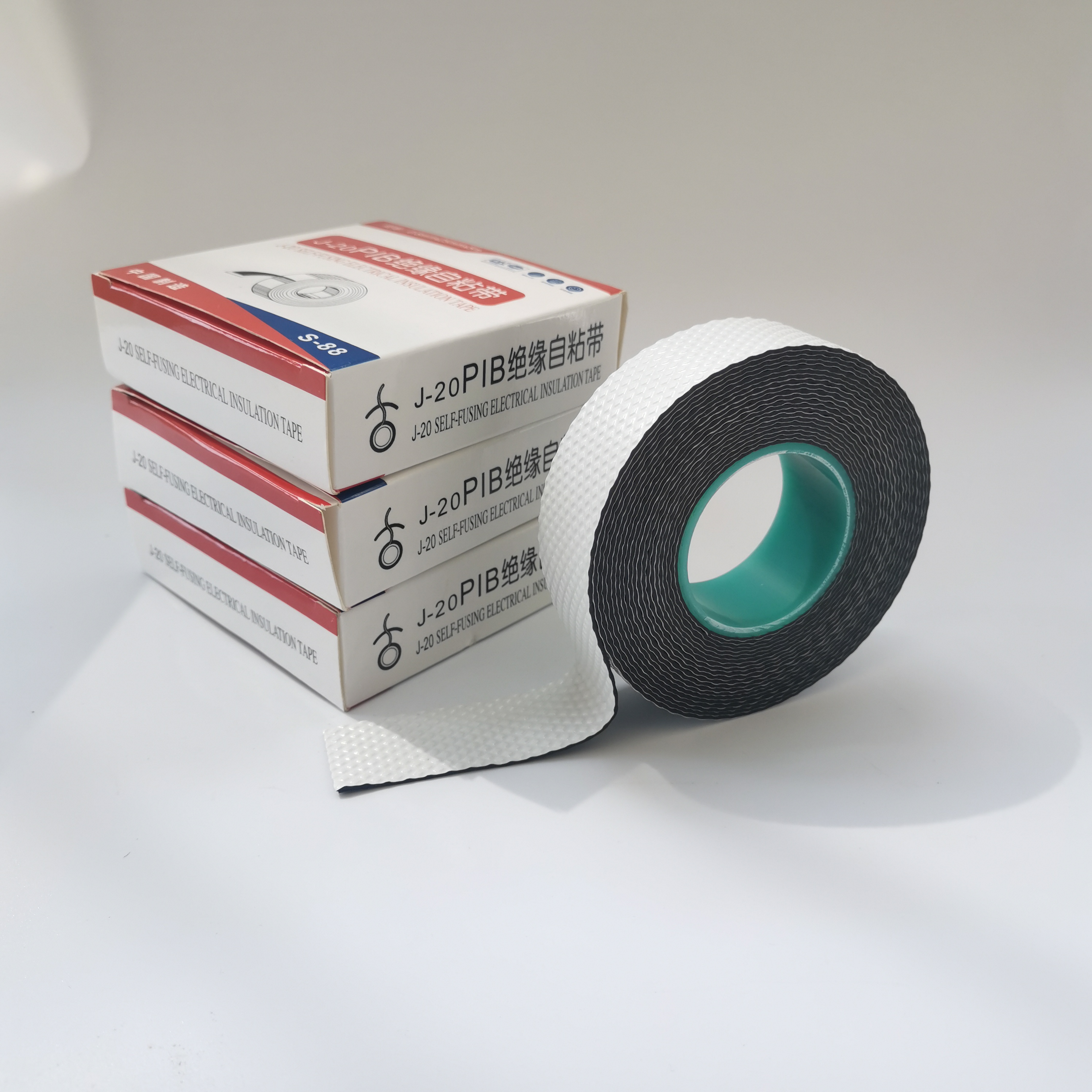

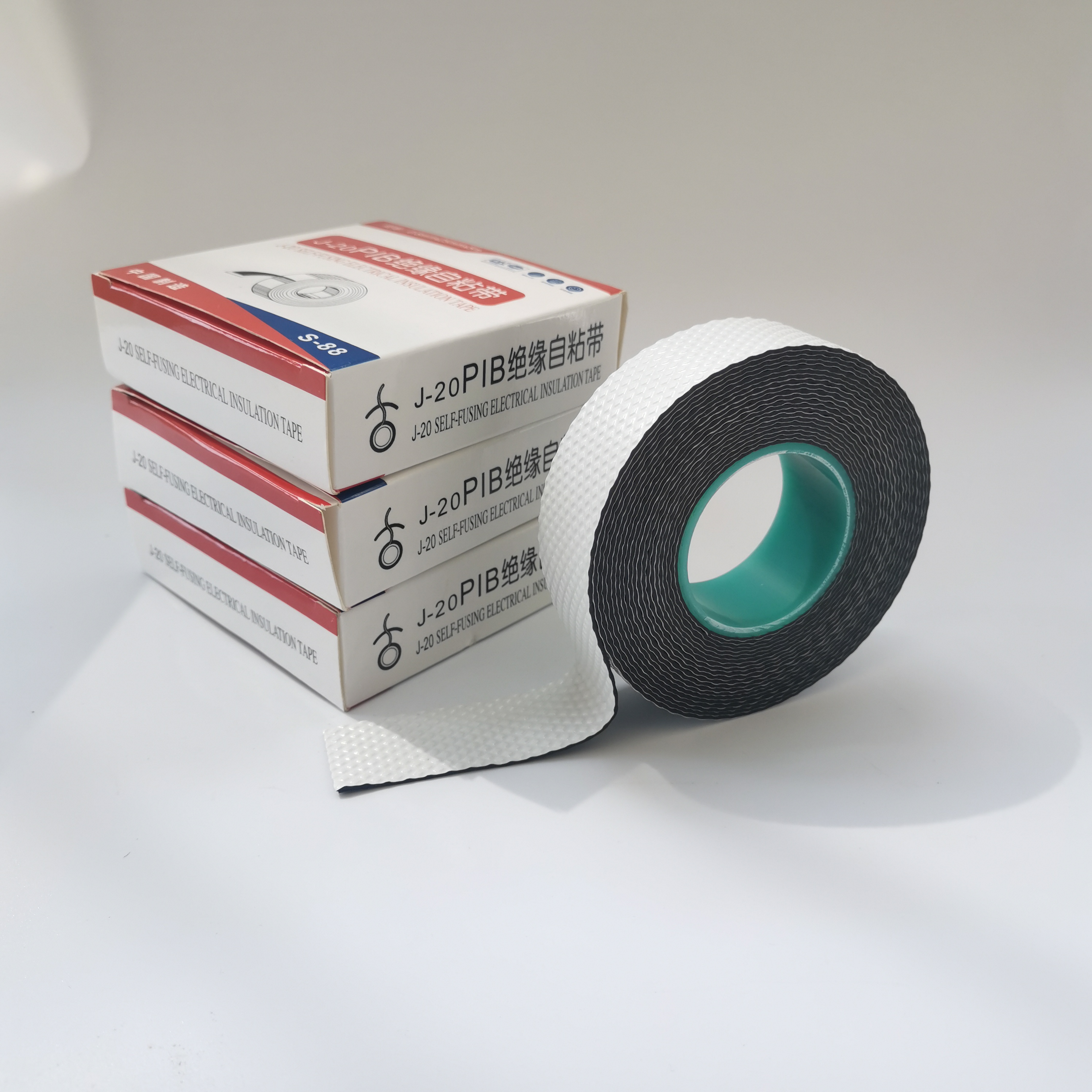

custom oil seals. This can result in improved productivity, higher quality output, and overall better performance of the equipment.Self-amalgamating tape can also be used for automotive repairs. It can be wrapped around hoses and pipes in the engine compartment to prevent leaks and ensure proper functioning of the vehicle

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.