Current location:Home > high pressure pump seal kit >

high pressure pump seal kit

2025-08-14 15:44

2025-08-14 15:09

2025-08-14 15:07

2025-08-14 15:05

2025-08-14 14:52

2025-08-14 14:44

2025-08-14 14:13

2025-08-14 13:36

2025-08-14 13:26

2025-08-14 13:12

Latest articles

In industrial machinery, skeleton oil seals are utilized in gearboxes, pumps, and compressors

. These seals protect the internal components from environmental contaminants and ensure that the lubricants remain intact, thus reducing wear and tear on machinery. The robustness of skeleton oil seals makes them ideal for high-performance applications where reliability is paramount.The 35x72x10 oil seal finds prevalent use in various applications across different industries

. Commonly, it is utilized in35x72x10 oil seal

For example, polyurethane is known for its excellent abrasion resistance and ability to maintain its seal under varying temperatures. Nitrile rubber, on the other hand, provides a good balance of chemical resistance and cost-effectiveness. Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance hydraulic seal kits.

hydraulic seal kits.

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance

Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance Meanwhile, PTFE is often used in applications requiring very low friction and high chemical resistance hydraulic seal kits.

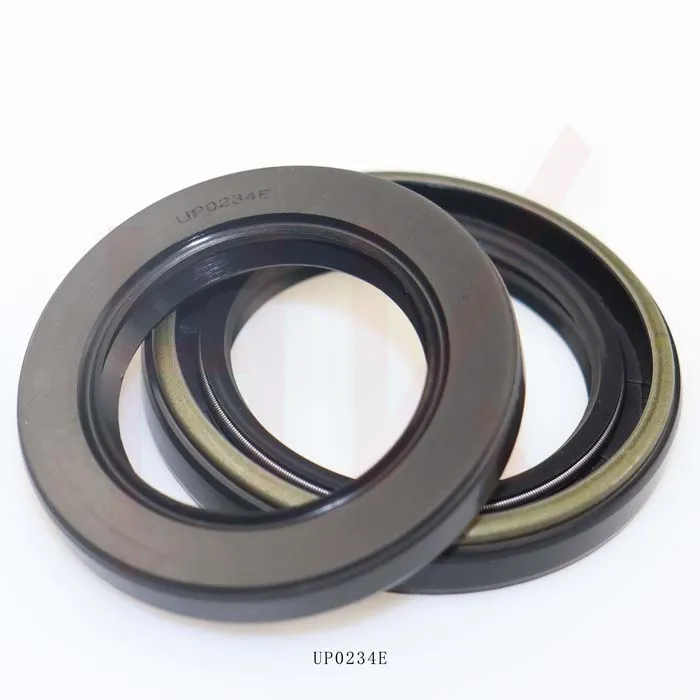

hydraulic seal kits.Furthermore, combi oil seals are known for their durability and longevity combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.The design must be such that it balances the need for a tight seal with the amount of friction generated during operation. Excessive friction can lead to wear and heat buildup, while insufficient sealing can allow fluid leakage. Therefore, engineers carefully select materials and dimensions to ensure optimal performance.

rotary lip seal