Current location:Home > hydraulic cylinder seal kit replacement >

hydraulic cylinder seal kit replacement

2025-08-15 02:42

2025-08-15 02:24

2025-08-15 02:24

2025-08-15 02:16

...

2025-08-15 01:58

2025-08-15 01:55

2025-08-15 01:45

2025-08-15 01:36

2025-08-15 00:33

2025-08-15 00:31

Latest articles

In industrial machinery, skeleton oil seals are utilized in gearboxes, pumps, and compressors

. These seals protect the internal components from environmental contaminants and ensure that the lubricants remain intact, thus reducing wear and tear on machinery. The robustness of skeleton oil seals makes them ideal for high-performance applications where reliability is paramount.Another important feature of hydraulic lip seals is their ability to reduce friction and wear on the moving parts of the hydraulic system

hydraulic lip seal. By creating a tight seal between the piston and cylinder, these seals help to minimize the loss of hydraulic fluid and prevent contamination of the system.

hydraulic lip seal. By creating a tight seal between the piston and cylinder, these seals help to minimize the loss of hydraulic fluid and prevent contamination of the system.

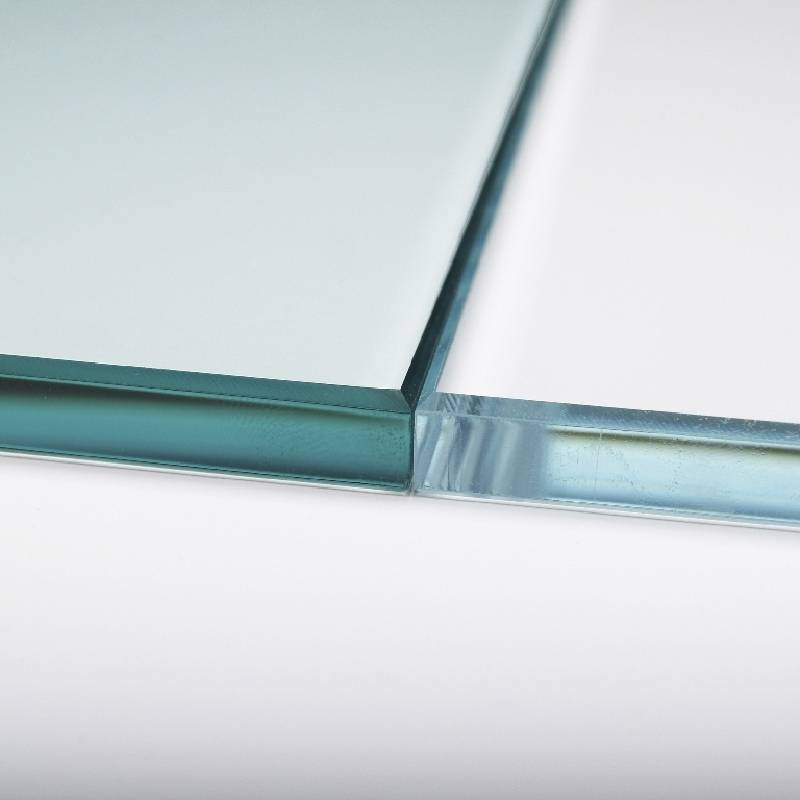

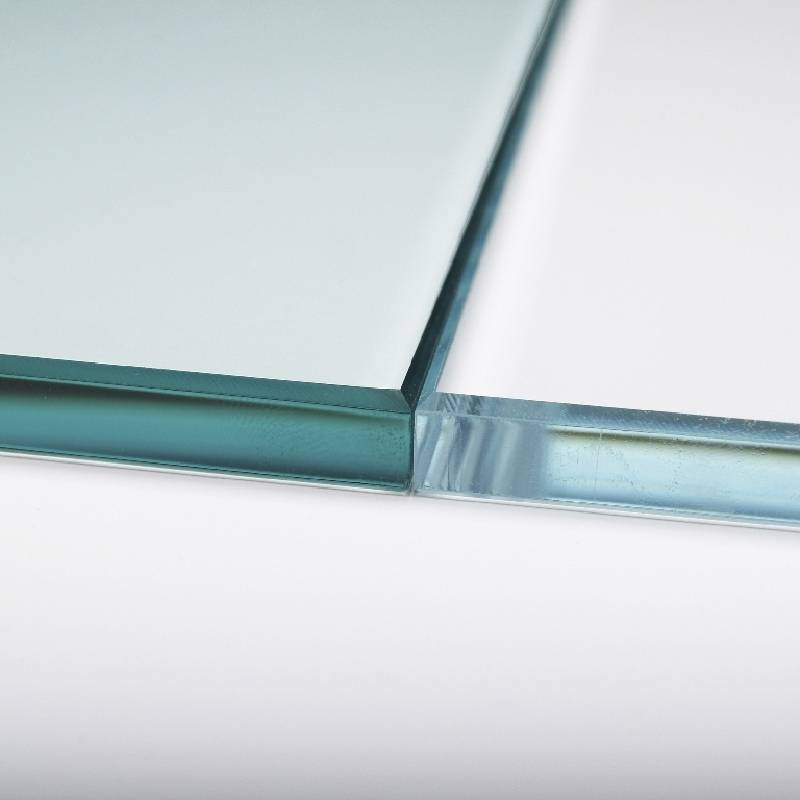

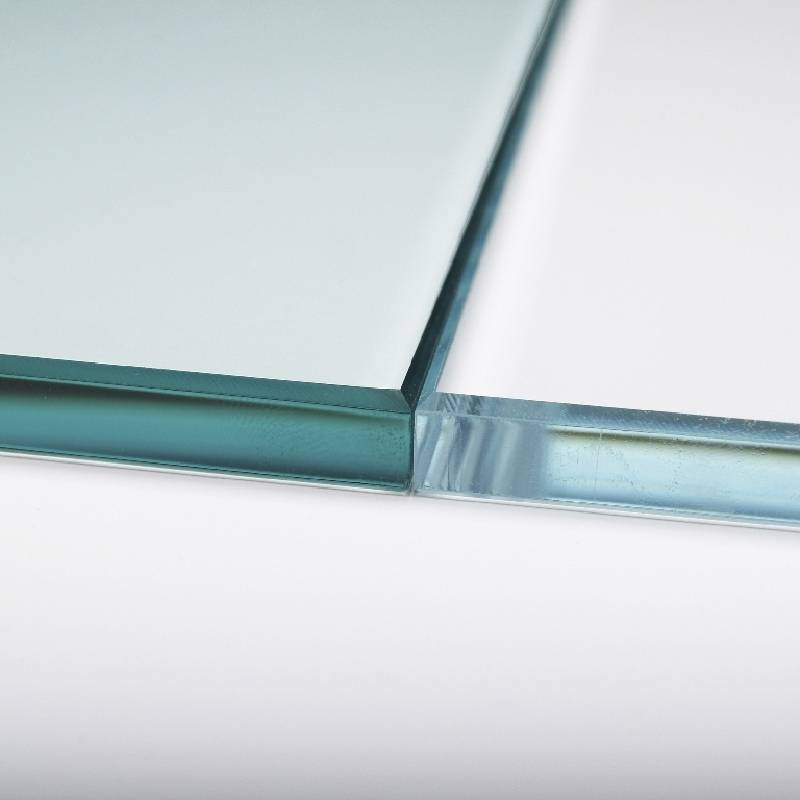

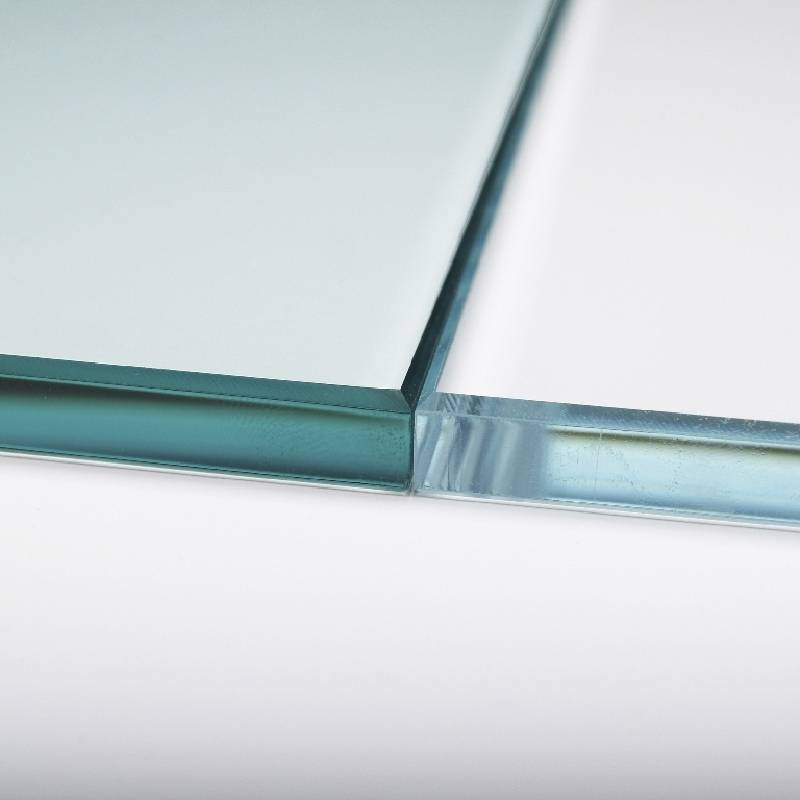

Furthermore, the energy costs associated with producing 6mm float glass have also increased significantly in recent years. The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production

The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production 6mm float glass price. In addition, the implementation of stricter environmental regulations has led to higher operating costs for manufacturers, further exacerbating the price increase.

6mm float glass price. In addition, the implementation of stricter environmental regulations has led to higher operating costs for manufacturers, further exacerbating the price increase.

The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production

The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production The process of manufacturing float glass requires a significant amount of electricity, and any fluctuations in energy prices can have a direct impact on the cost of production 6mm float glass price. In addition, the implementation of stricter environmental regulations has led to higher operating costs for manufacturers, further exacerbating the price increase.

6mm float glass price. In addition, the implementation of stricter environmental regulations has led to higher operating costs for manufacturers, further exacerbating the price increase.This mirror is not just a decorative item; it's a statement piece that tells a story. It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it

It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it silver glam mirror. The Silver Glam Mirror embodies glamour and elegance, exuding a sense of luxury that can instantly elevate the mood of a room. It becomes a focal point, drawing admiring glances and sparking conversations.

silver glam mirror. The Silver Glam Mirror embodies glamour and elegance, exuding a sense of luxury that can instantly elevate the mood of a room. It becomes a focal point, drawing admiring glances and sparking conversations.

It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it

It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it silver glam mirror. The Silver Glam Mirror embodies glamour and elegance, exuding a sense of luxury that can instantly elevate the mood of a room. It becomes a focal point, drawing admiring glances and sparking conversations.

silver glam mirror. The Silver Glam Mirror embodies glamour and elegance, exuding a sense of luxury that can instantly elevate the mood of a room. It becomes a focal point, drawing admiring glances and sparking conversations.Raw material quality is another crucial factor that affects the quality of tempered glass. High-quality raw materials, such as clear, pure, and uniform glass, are essential for producing high-performance tempered glass. Contaminants, such as iron and nickel particles, can significantly reduce the glass's transparency and strength, leading to poor quality. Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass tempered glass quality.

tempered glass quality.

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass

Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass Therefore, it is essential to use high-quality raw materials to ensure the desired performance and safety standards of tempered glass tempered glass quality.

tempered glass quality.