hydraulic cylinder wipers

wheel hub seal. This noise is caused by the lack of lubrication in the wheel hub, which can lead to metal-on-metal contact and damage.

3. Pressure Maintenance In many applications, oil seals are designed to maintain pressure within a system. By preventing the exit of oil and the entrance of contaminants, they help in sustaining the necessary pressure levels for optimal operation. This function is especially important in hydraulic systems, where pressure plays a critical role in performance.

what is the function of oil seal

Failure to do so can result in costly repairs and downtime, as well as potential safety hazards Failure to do so can result in costly repairs and downtime, as well as potential safety hazards

Failure to do so can result in costly repairs and downtime, as well as potential safety hazards Failure to do so can result in costly repairs and downtime, as well as potential safety hazards excavator cylinder seal kits.

excavator cylinder seal kits.

2 inch hydraulic cylinder seal kit. By investing in a high-quality 2-inch hydraulic cylinder seal kit, operators can minimize downtime, reduce repair costs, and extend the lifespan of their hydraulic systems.

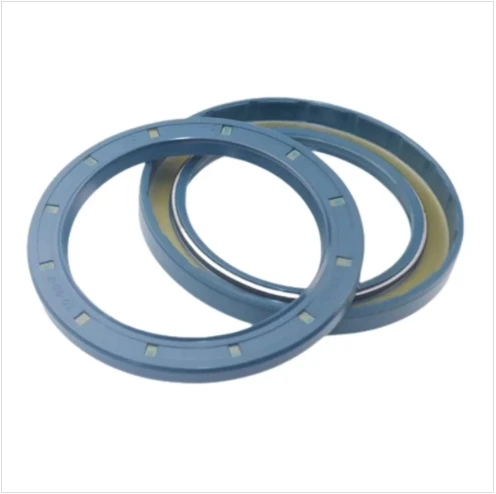

Oil seals work by creating a tight seal around the rotating shaft. This prevents oil and other fluids from escaping while allowing the shaft to rotate smoothly. The seal is usually made up of a lip that fits snugly against the shaft, preventing any leaks from occurring. Some oil seals also have additional features, such as springs or gaskets, to provide extra support and ensure a secure fit.

oil seal for rotating shaft

In recent years, the push for renewable energy sources has gained significant momentum, as more homeowners seek alternative ways to power their homes while reducing their carbon footprint. Among these alternatives, solar energy stands out due to its efficiency, sustainability, and cost-effectiveness. However, the initial investment for solar panels can be a barrier for many. This is where the concept of “no cost solar panels” comes into play, offering a solution that allows homeowners to harness the power of the sun without the upfront expenses.