Current location:Home > hydraulic cylinder repair kits >

hydraulic cylinder repair kits

2025-08-14 17:52

2025-08-14 17:36

2025-08-14 17:11

2025-08-14 17:09

2025-08-14 17:08

2025-08-14 16:54

2025-08-14 16:52

2025-08-14 16:51

2025-08-14 16:14

2025-08-14 15:53

Latest articles

Furthermore, wheel bearing grease seals act as a protective barrier against contaminants that can cause premature wear and damage to the bearings. Dirt, water, and other debris can easily enter the bearings if the seals are not properly maintained, leading to corrosion and friction that can compromise the wheel assembly system's efficiency and safety.

To mitigate these issues, regular maintenance and inspection of the oil seals are essential hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.In automotive engineering, every millimeter counts, and so does every gram of pressure exerted by the seal. The design of the wheel hub seal is meticulously crafted to withstand the vagaries of temperature fluctuations and the constant friction it endures. Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat

Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat wheel hub seal.

wheel hub seal.

Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat

Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat Its material composition must be durable enough to flex without cracking in cold weather yet resilient enough to maintain its shape under high-speed rotation and heat wheel hub seal.

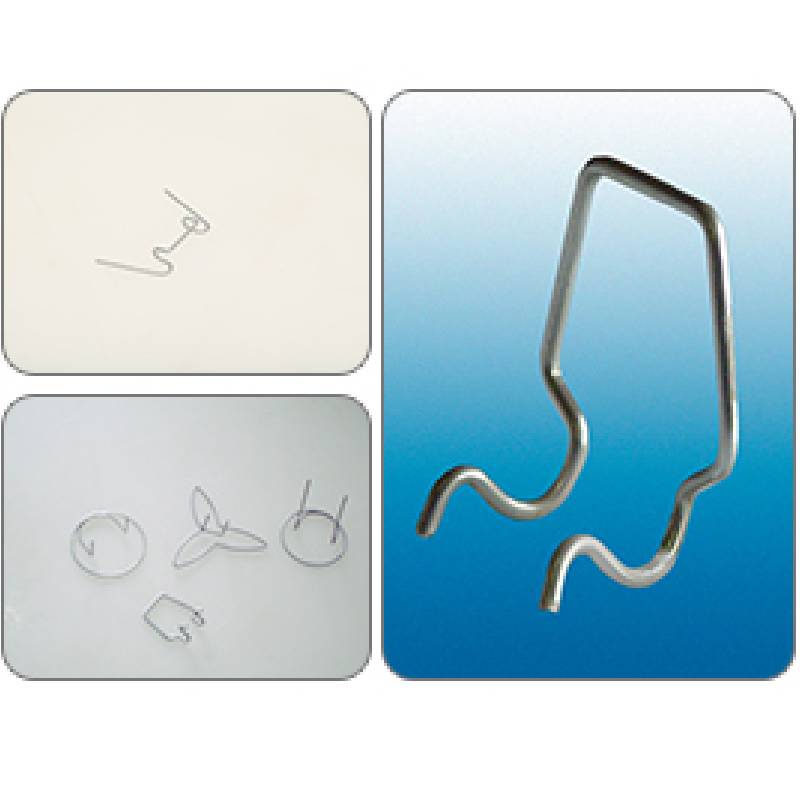

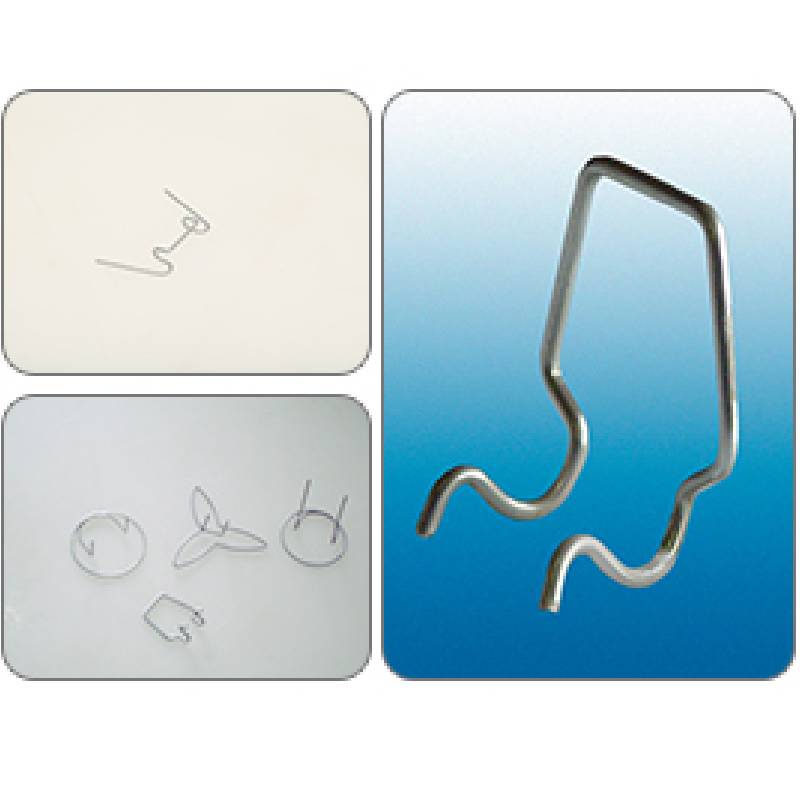

wheel hub seal.Moreover, bow plant supports aid in photosynthesis by ensuring that each part of the plant receives adequate sunlight bow plant supports. When plants are allowed to sprawl on the ground or against other plants, they may shade one another, leading to uneven growth and reduced flowering. With the help of supports, every leaf has the chance to maximize its exposure to the sun, enhancing the plant's ability to produce energy and, ultimately, blooms.

bow plant supports. When plants are allowed to sprawl on the ground or against other plants, they may shade one another, leading to uneven growth and reduced flowering. With the help of supports, every leaf has the chance to maximize its exposure to the sun, enhancing the plant's ability to produce energy and, ultimately, blooms.

bow plant supports. When plants are allowed to sprawl on the ground or against other plants, they may shade one another, leading to uneven growth and reduced flowering. With the help of supports, every leaf has the chance to maximize its exposure to the sun, enhancing the plant's ability to produce energy and, ultimately, blooms.

bow plant supports. When plants are allowed to sprawl on the ground or against other plants, they may shade one another, leading to uneven growth and reduced flowering. With the help of supports, every leaf has the chance to maximize its exposure to the sun, enhancing the plant's ability to produce energy and, ultimately, blooms.Secondly, the spring rate is another critical factor. It defines how much the spring will compress or extend per unit of force applied. A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility

A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery.

coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery.

A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility

A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery.

coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery.