Current location:Home > high pressure lip seal >

high pressure lip seal

2025-08-16 03:09

2025-08-16 03:01

Additionally, the 22% 40% 7% oil seal is designed for long-lasting performance, with a high resistance to wear and tear

22 40 7 oil seal. This oil seal is built to withstand the demands of continuous use and heavy loads, making it a reliable choice for equipment that operates in challenging environments. The durability of the 22% 40% 7% oil seal ensures that it can provide effective sealing for an extended period, reducing the need for frequent replacements and maintenance.

22 40 7 oil seal. This oil seal is built to withstand the demands of continuous use and heavy loads, making it a reliable choice for equipment that operates in challenging environments. The durability of the 22% 40% 7% oil seal ensures that it can provide effective sealing for an extended period, reducing the need for frequent replacements and maintenance.

...

2025-08-16 03:00

2025-08-16 02:57

One of the key factors that determine the effectiveness of an oil seal is its compatibility with the oil being used. Different oils have different properties, such as viscosity and chemical composition, which can affect the seal's performance. Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application

Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application 20 35 7 oil seal.

20 35 7 oil seal.

Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application

Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application Therefore, it is essential to choose an oil seal that is specifically designed for the type of oil being used in the application 20 35 7 oil seal.

20 35 7 oil seal.

...

2025-08-16 02:51

2025-08-16 02:31

2025-08-16 02:27

2025-08-16 02:15

2025-08-16 01:54

2025-08-16 00:46

Latest articles

The use of oil seals like the 38x52x7 is paramount in preventing contamination 38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.

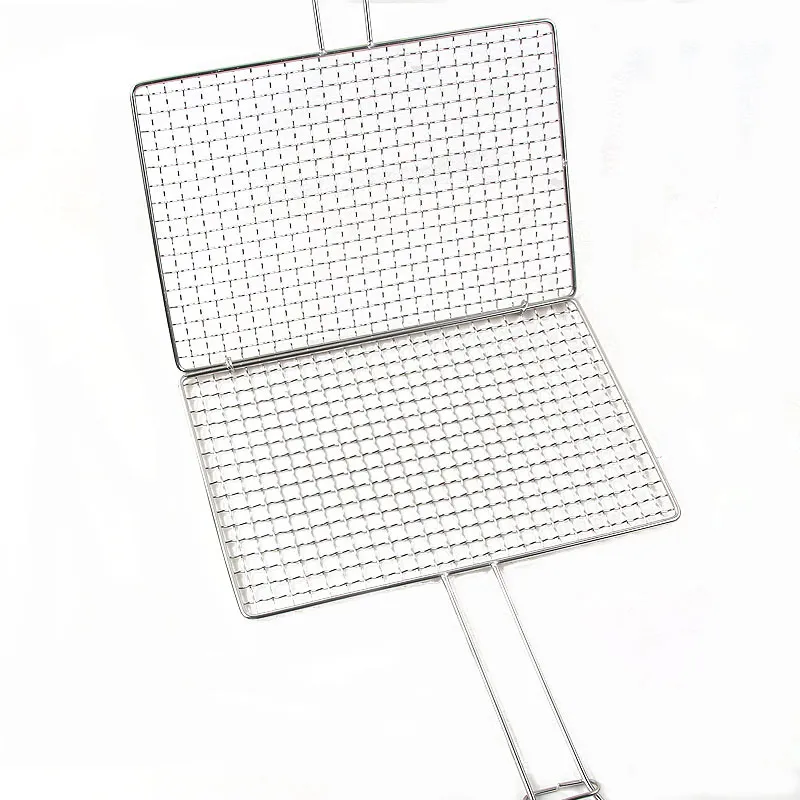

38x52x7 oil seal. Oil leaks can not only compromise the performance of machinery but also pose environmental hazards. By effectively containing lubricants within their designated systems, these seals ensure that machinery runs smoothly while minimizing ecological impact.One of the primary benefits of using proofing racks is their ability to streamline the proofing process. These racks often come equipped with features such as adjustable shelves, ventilation, and sometimes even integrated heating elements. This versatility allows bakers to proof multiple batches of dough simultaneously, thus enhancing efficiency in a busy bakery setting. With a proofing rack, bakers can ensure that all their dough rises evenly and consistently, leading to uniformly baked products.

proofing racks baking