Current location:Home > industrial oil seals >

industrial oil seals

2025-08-15 03:23

2025-08-15 03:18

2025-08-15 02:58

2025-08-15 01:59

2025-08-15 01:58

2025-08-15 01:41

2025-08-15 01:37

Regular inspections of the wheel hub oil seals are essential for proactive maintenance wheel hub oil seal. If a technician notices cracking, brittleness, or visible oil stains around the wheel hub, it's a clear sign that the seal needs to be replaced. Neglecting this simple task can result in costly repairs down the line, including the replacement of entire wheel hubs or even more extensive drivetrain components.

wheel hub oil seal. If a technician notices cracking, brittleness, or visible oil stains around the wheel hub, it's a clear sign that the seal needs to be replaced. Neglecting this simple task can result in costly repairs down the line, including the replacement of entire wheel hubs or even more extensive drivetrain components.

wheel hub oil seal. If a technician notices cracking, brittleness, or visible oil stains around the wheel hub, it's a clear sign that the seal needs to be replaced. Neglecting this simple task can result in costly repairs down the line, including the replacement of entire wheel hubs or even more extensive drivetrain components.

wheel hub oil seal. If a technician notices cracking, brittleness, or visible oil stains around the wheel hub, it's a clear sign that the seal needs to be replaced. Neglecting this simple task can result in costly repairs down the line, including the replacement of entire wheel hubs or even more extensive drivetrain components.

...

2025-08-15 01:37

2025-08-15 00:45

Moreover, dust lip seals contribute to overall system cleanliness, which is crucial in industries where contamination control is vital, such as food processing, pharmaceuticals, and semiconductor manufacturing. They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs dust lip seal.

dust lip seal.

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs dust lip seal.

dust lip seal.

...

2025-08-15 00:45

Latest articles

The importance of motor seal kits lies not only in their ability to maintain system integrity but also in their role in energy conservation. Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards

Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards motor seal kit. Moreover, contaminated motors can suffer from increased wear, leading to premature failure and costly repairs.

motor seal kit. Moreover, contaminated motors can suffer from increased wear, leading to premature failure and costly repairs.

Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards

Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards Leaking seals can lead to significant loss of fluids, increasing operational costs and posing environmental hazards motor seal kit. Moreover, contaminated motors can suffer from increased wear, leading to premature failure and costly repairs.

motor seal kit. Moreover, contaminated motors can suffer from increased wear, leading to premature failure and costly repairs.The 40x55x8 mm oil seal finds applications across various industries. In automotive systems, it is commonly used in engines and transmissions to contain lubricants and hydraulic fluids. This prevents oil leaks that could lead to inefficient operation or costly damages. Additionally, these seals are pivotal in construction machinery, agricultural equipment, and even household appliances like washing machines. In each of these applications, the oil seal helps maintain the integrity of the lubrication system, thereby enhancing efficiency and extending the life of the machine.

40x55x8 oil seal

In addition to clear adhesive and magnetic tape, there are also specialized types of splicing tape designed for specific purposes

. For example, there is pressure-sensitive tape that is used in high-speed film editing machines to ensure quick and accurate splicing. There is also perforated tape that is used in conjunction with splicing equipment to create precise cuts in the film.Moreover, PVC electrical tape offers mechanical protection. It shields wires from environmental factors such as moisture, dust, and physical damage, extending the lifespan of the wiring. Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments pvc insulation electrical tape.

pvc insulation electrical tape.

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments pvc insulation electrical tape.

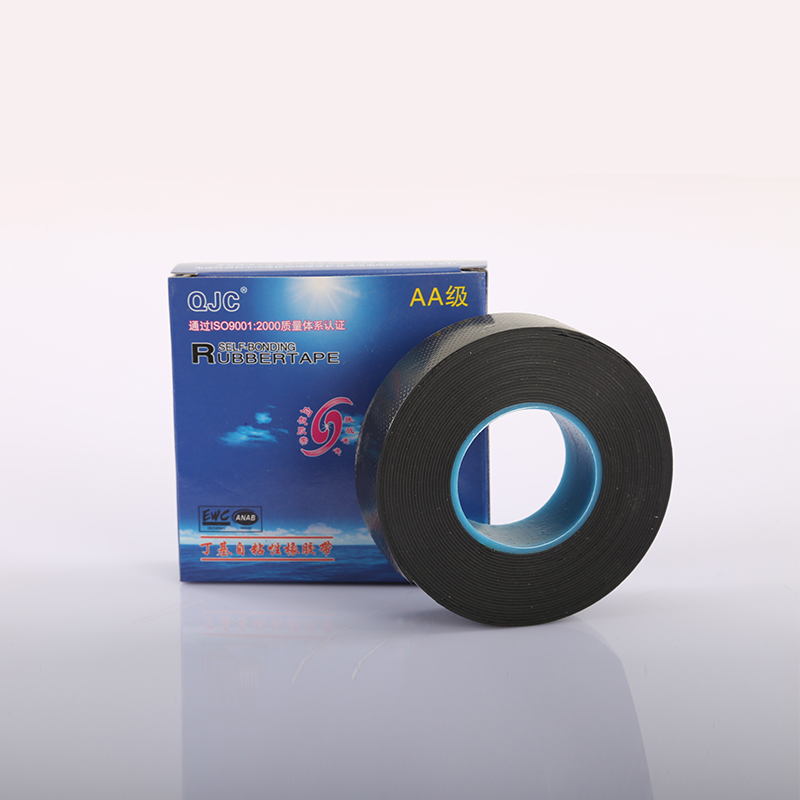

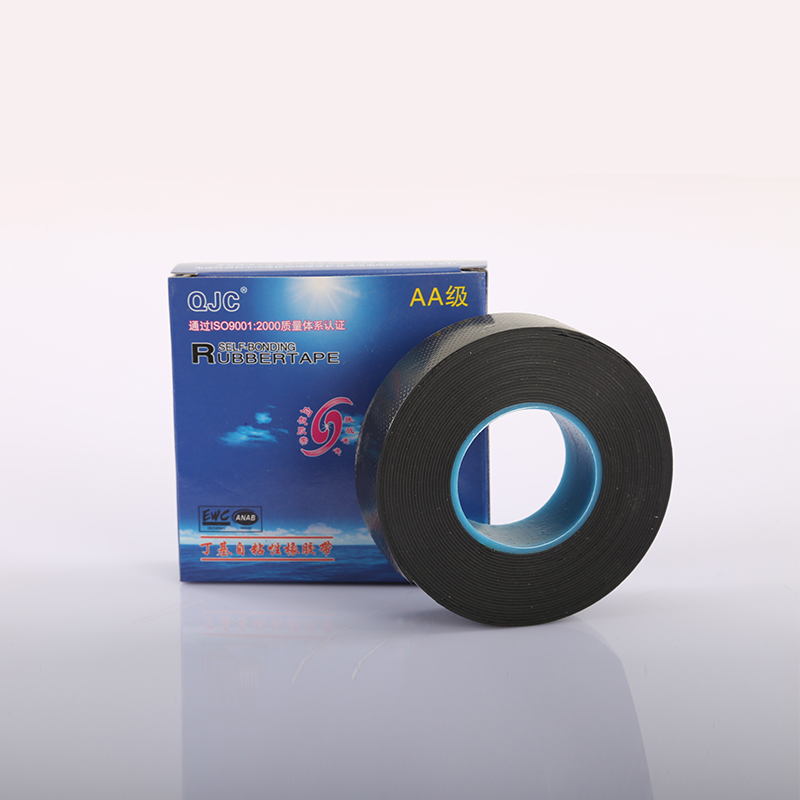

pvc insulation electrical tape.One of the key advantages of flame-resistant tape is its ability to maintain its structural integrity at high temperatures. This means that even if a fire breaks out near the taped area, it will not easily melt or burn through, providing an additional layer of protection. Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition

Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition flame resistant tape.

flame resistant tape.

Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition

Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition flame resistant tape.

flame resistant tape.In the aerospace industry, strip seals play a critical role in aircraft construction and maintenance

strip seal. These seals are used in hydraulic systems, fuel tanks, and other components to prevent leaks and ensure the safety and performance of the aircraft. Strip seals in aerospace applications must meet stringent requirements for temperature resistance, pressure tolerance, and compatibility with various fluids.

strip seal. These seals are used in hydraulic systems, fuel tanks, and other components to prevent leaks and ensure the safety and performance of the aircraft. Strip seals in aerospace applications must meet stringent requirements for temperature resistance, pressure tolerance, and compatibility with various fluids.