Current location:Home > oil seal companies >

oil seal companies

2025-08-14 15:29

2025-08-14 15:21

2025-08-14 15:00

2025-08-14 14:50

2025-08-14 14:40

2025-08-14 14:37

2025-08-14 14:26

2025-08-14 14:09

2025-08-14 14:06

Proper installation of oil seals is crucial to ensure they function effectively. Before installing a new oil seal, it is important to clean the shaft and housing to remove any dirt or debris that could damage the seal

17x30x7 oil seal. The seal should be pressed into place using a proper installation tool to avoid any damage to the sealing element.

17x30x7 oil seal. The seal should be pressed into place using a proper installation tool to avoid any damage to the sealing element.

...

2025-08-14 13:30

Latest articles

Replacing hydraulic seals is a task that requires precision and attention to detail. It is important to use the correct replacement seals that are compatible with the specific hydraulic system. The first step is to identify the type and size of the seals that need to be replaced. This information can usually be found in the equipment manual or by consulting with a hydraulic system specialist

hydraulic seal replacement.

hydraulic seal replacement.

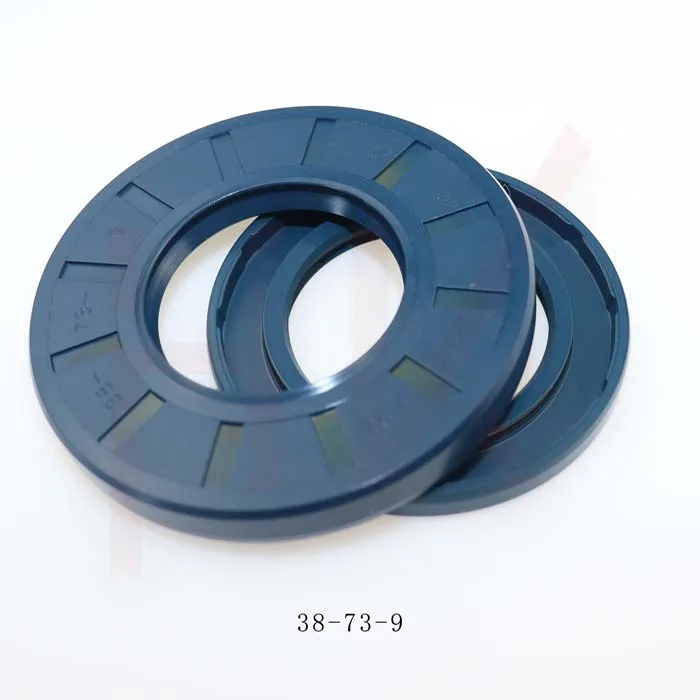

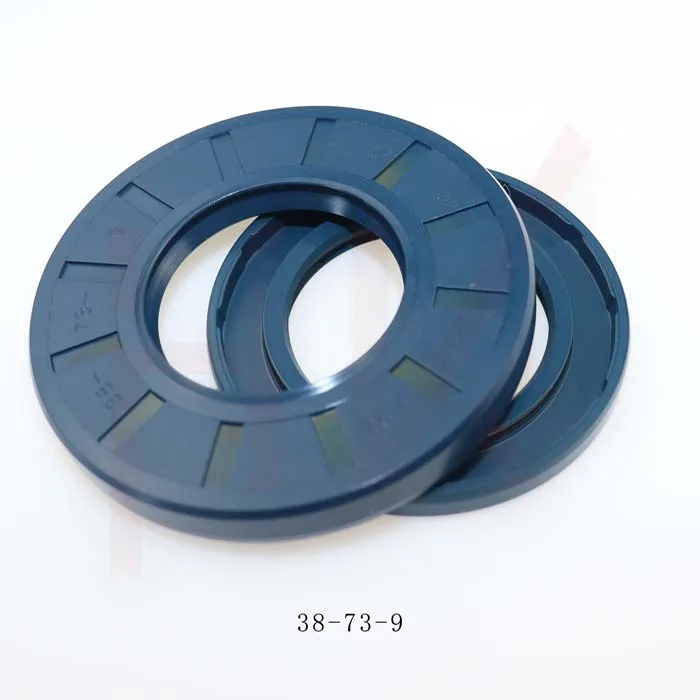

Moving on to 2047%, this number might seem unusual but it represents the potential increase in seal life expectancy due to advancements in material science and design. In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs

In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs 32 47 7 oil seal. These enhancements include improved rubber compounds, advanced manufacturing processes, and the integration of anti-extrusion rings, all of which contribute to enhanced sealing efficiency and extended service life.

32 47 7 oil seal. These enhancements include improved rubber compounds, advanced manufacturing processes, and the integration of anti-extrusion rings, all of which contribute to enhanced sealing efficiency and extended service life.

In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs

In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs In recent years, there have been significant breakthroughs in oil seal technology, with some innovations increasing seal longevity by as much as 2047% compared to traditional designs 32 47 7 oil seal. These enhancements include improved rubber compounds, advanced manufacturing processes, and the integration of anti-extrusion rings, all of which contribute to enhanced sealing efficiency and extended service life.

32 47 7 oil seal. These enhancements include improved rubber compounds, advanced manufacturing processes, and the integration of anti-extrusion rings, all of which contribute to enhanced sealing efficiency and extended service life.Moreover, the T runner offers significant flexibility in terms of material and finish. Available in a plethora of textures, colors, and finishes, designers and homeowners can easily select options that best match their existing decor or desired themes. From sleek metallics that evoke a modern industrial vibe to rich wooden textures that offer warmth and coziness, the possibilities are virtually limitless. This versatility allows for creative freedom, enabling spaces to embody unique personality traits and styles.

t runner for ceiling