hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

Current location:Home > hydraulic cylinder dust seal >

hydraulic cylinder dust seal

The design of hub dust seals varies depending on the application and environmental conditions hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

hub dust seal. Some seals incorporate metal inserts for added strength and durability, while others may have unique compounds to withstand extreme temperatures or resist chemical corrosion. It's crucial to choose the right type of seal for each specific application to ensure maximum effectiveness.

...

2025-08-15 05:41

2025-08-15 05:27

2025-08-15 05:13

Another important aspect of industrial oil seals is their ease of installation and maintenance industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

...

2025-08-15 05:02

2025-08-15 04:38

In automotive applications, metal oil seals are used in engine oil pans, transmission casings, and differentials to prevent oil leaks metal oil seal. In aerospace engineering, they are crucial in ensuring the lubrication systems function flawlessly in aircraft engines. Industrial settings, such as factories and power plants, also rely on these seals for machinery maintenance and safety.

metal oil seal. In aerospace engineering, they are crucial in ensuring the lubrication systems function flawlessly in aircraft engines. Industrial settings, such as factories and power plants, also rely on these seals for machinery maintenance and safety.

metal oil seal. In aerospace engineering, they are crucial in ensuring the lubrication systems function flawlessly in aircraft engines. Industrial settings, such as factories and power plants, also rely on these seals for machinery maintenance and safety.

metal oil seal. In aerospace engineering, they are crucial in ensuring the lubrication systems function flawlessly in aircraft engines. Industrial settings, such as factories and power plants, also rely on these seals for machinery maintenance and safety.

...

2025-08-15 04:33

2025-08-15 04:32

In addition to extending the lifespan of the equipment, seal kits also help to improve the overall performance of industrial machinery. When seals are worn out or damaged, they can cause the equipment to operate less efficiently, leading to decreased productivity and increased energy consumption. By replacing the seals with a new seal kit, you can restore the proper functioning of the equipment and ensure that it operates at maximum efficiency

seal kit for cylinder.

seal kit for cylinder.

...

2025-08-15 04:31

2025-08-15 04:19

2025-08-15 04:01

Latest articles

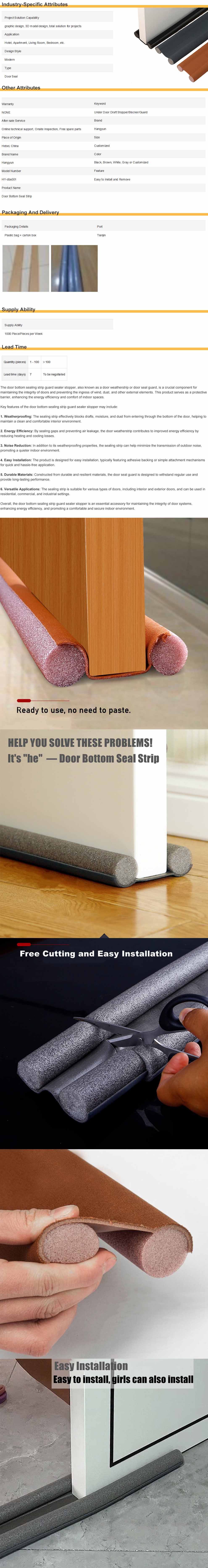

Choosing the right weather stripping lubricant is critical. Silicone-based lubricants are often recommended as they are water-resistant and do not attract dirt and dust. They provide a smooth finish that ensures ease of movement for sliding components. Additionally, silicone lubricants do not dry out or become sticky over time, making them an excellent long-term solution.

weather stripping lubricant