Current location:Home > oil seal suppliers >

oil seal suppliers

2025-08-14 19:39

2025-08-14 19:29

2025-08-14 19:28

2025-08-14 19:27

2025-08-14 19:01

2025-08-14 18:29

2025-08-14 18:26

2025-08-14 18:21

2025-08-14 18:06

2025-08-14 17:56

Latest articles

Regular inspection and maintenance of the front wheel oil seal are crucial to ensure its proper functioning. Signs of a damaged or worn-out oil seal include oil leaks around the front wheel hub, increased noise or vibration when driving, or uneven tire wear

front wheel oil seal. If any of these symptoms are observed, it is important to replace the front wheel oil seal promptly to prevent further damage to the vehicle.

front wheel oil seal. If any of these symptoms are observed, it is important to replace the front wheel oil seal promptly to prevent further damage to the vehicle.

However, like all mechanical parts, hub oil seals are not immune to wear and tear. Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade

Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade hub oil seal. Symptoms of a failing hub oil seal may include oil spots on the inside of wheel arches, increased friction within the wheel hub, or a noticeable drop in oil levels.

hub oil seal. Symptoms of a failing hub oil seal may include oil spots on the inside of wheel arches, increased friction within the wheel hub, or a noticeable drop in oil levels.

Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade

Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade Over time, exposure to extreme temperatures, road grime, and the constant motion of the wheel can cause them to degrade hub oil seal. Symptoms of a failing hub oil seal may include oil spots on the inside of wheel arches, increased friction within the wheel hub, or a noticeable drop in oil levels.

hub oil seal. Symptoms of a failing hub oil seal may include oil spots on the inside of wheel arches, increased friction within the wheel hub, or a noticeable drop in oil levels.The importance of a well-functioning hub seal cannot be overstated hub seal. A compromised seal can lead to lubricant loss, causing excessive wear on moving parts, increased friction, and potential system failure. It can also allow contaminants to enter, leading to damage, corrosion, and reduced efficiency. Therefore, regular inspection and maintenance of hub seals are crucial aspects of preventive maintenance programs.

hub seal. A compromised seal can lead to lubricant loss, causing excessive wear on moving parts, increased friction, and potential system failure. It can also allow contaminants to enter, leading to damage, corrosion, and reduced efficiency. Therefore, regular inspection and maintenance of hub seals are crucial aspects of preventive maintenance programs.

hub seal. A compromised seal can lead to lubricant loss, causing excessive wear on moving parts, increased friction, and potential system failure. It can also allow contaminants to enter, leading to damage, corrosion, and reduced efficiency. Therefore, regular inspection and maintenance of hub seals are crucial aspects of preventive maintenance programs.

hub seal. A compromised seal can lead to lubricant loss, causing excessive wear on moving parts, increased friction, and potential system failure. It can also allow contaminants to enter, leading to damage, corrosion, and reduced efficiency. Therefore, regular inspection and maintenance of hub seals are crucial aspects of preventive maintenance programs.Moreover, dry verge systems are designed to provide superior protection against wind and water infiltration. Because they do not rely on mortar for fixation, dry verge terracotta installations create a watertight seal, reducing the risk of leaks that can lead to costly repair work. This feature is particularly advantageous in regions prone to heavy rainfall or strong winds, where traditional roofing solutions may struggle.

dry verge terracotta

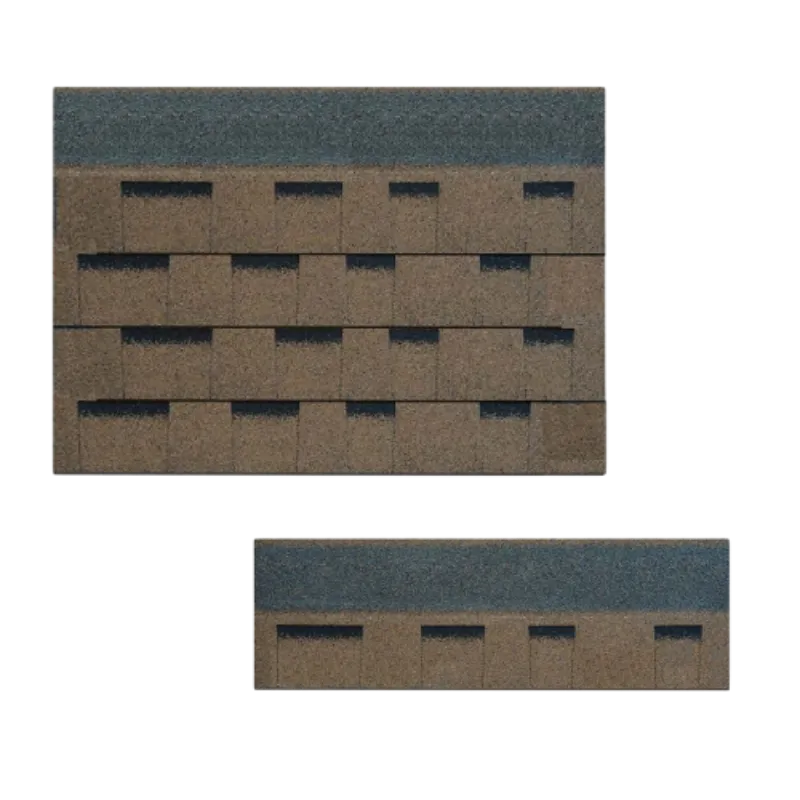

Moreover, simulated clay tile metal roofing panels are designed to resist corrosion, fading, and warping

. They have a protective coating that safeguards against UV rays and extreme weather conditions, ensuring their vibrant appearance and structural integrity over time. This durability means that homeowners can enjoy peace of mind, knowing that their investment will stand the test of time.