Current location:Home > hydraulic ram seals >

hydraulic ram seals

2025-08-14 03:27

2025-08-14 02:52

2025-08-14 02:48

2025-08-14 02:48

When purchasing a seal kit for a hydraulic motor, it is essential to consider the specific make and model of the motor. Each motor has unique requirements in terms of seal sizes and materials. Using the wrong seal kit can lead to improper sealing and potential damage to the motor

seal kit for hydraulic motor.

seal kit for hydraulic motor.

...

2025-08-14 02:27

2025-08-14 02:23

2025-08-14 02:15

2025-08-14 02:03

2025-08-14 02:01

2025-08-14 01:45

Latest articles

When selecting a seal kit, it is essential to choose one that is compatible with the specific make and model of your hydraulic motor seal kit for hydraulic motor. Manufacturers design these kits to exact specifications, ensuring that each seal fits correctly and provides the necessary level of protection. Improper seals or generic substitutes may seem cost-effective initially, but they often fail to provide the same level of security and reliability, leading to more significant problems down the line.

seal kit for hydraulic motor. Manufacturers design these kits to exact specifications, ensuring that each seal fits correctly and provides the necessary level of protection. Improper seals or generic substitutes may seem cost-effective initially, but they often fail to provide the same level of security and reliability, leading to more significant problems down the line.

seal kit for hydraulic motor. Manufacturers design these kits to exact specifications, ensuring that each seal fits correctly and provides the necessary level of protection. Improper seals or generic substitutes may seem cost-effective initially, but they often fail to provide the same level of security and reliability, leading to more significant problems down the line.

seal kit for hydraulic motor. Manufacturers design these kits to exact specifications, ensuring that each seal fits correctly and provides the necessary level of protection. Improper seals or generic substitutes may seem cost-effective initially, but they often fail to provide the same level of security and reliability, leading to more significant problems down the line.In addition to protecting the cylinder from contaminants, dust seals also help maintain the proper lubrication levels within the system. When dust and dirt particles enter the cylinder, they can mix with the hydraulic fluid and create abrasive sludge. This not only increases friction within the cylinder but also reduces the effectiveness of the lubrication, leading to increased wear on the moving parts. By keeping out contaminants, dust seals help ensure that the hydraulic system operates smoothly and efficiently.

In addition to its practical applications, black metal mesh sheet is also used for decorative purposes. Its intricate weave patterns and dark color can add a touch of elegance and sophistication to interior and exterior design projects. From room dividers and wall panels to furniture and lighting fixtures, black metal mesh sheet can enhance the aesthetics of any space.

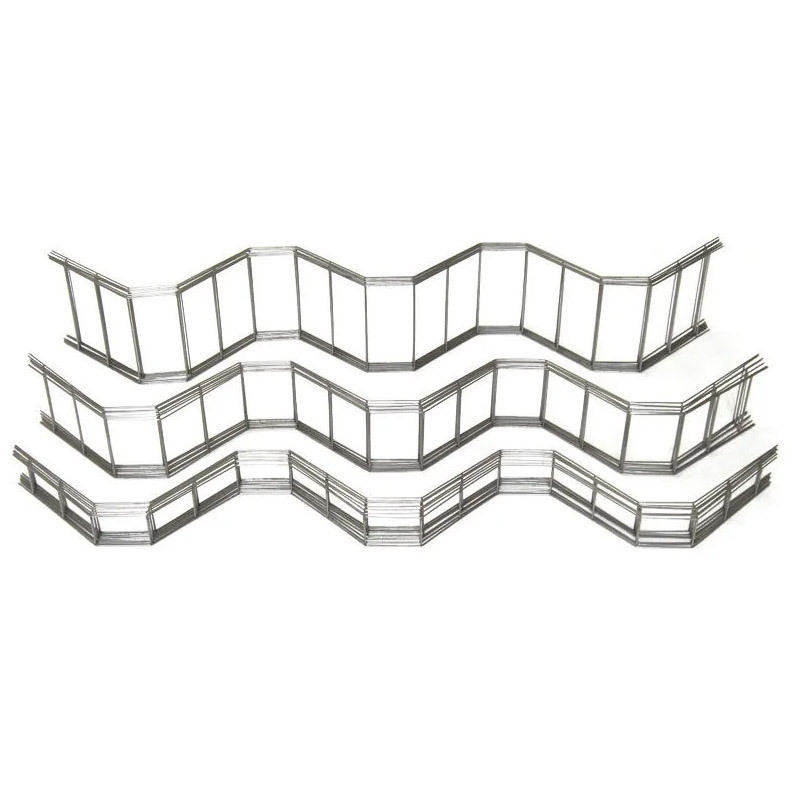

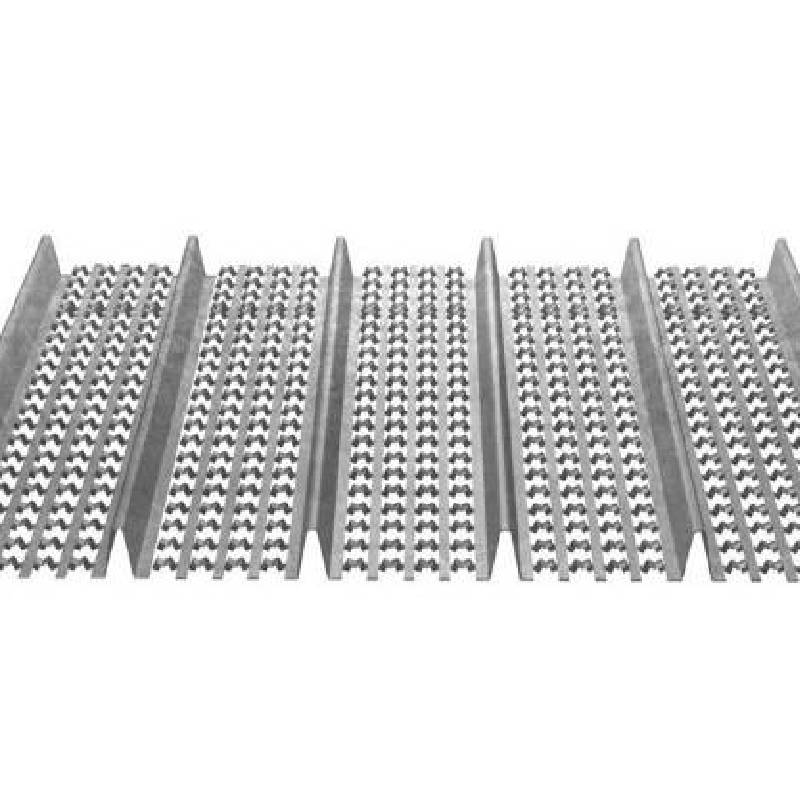

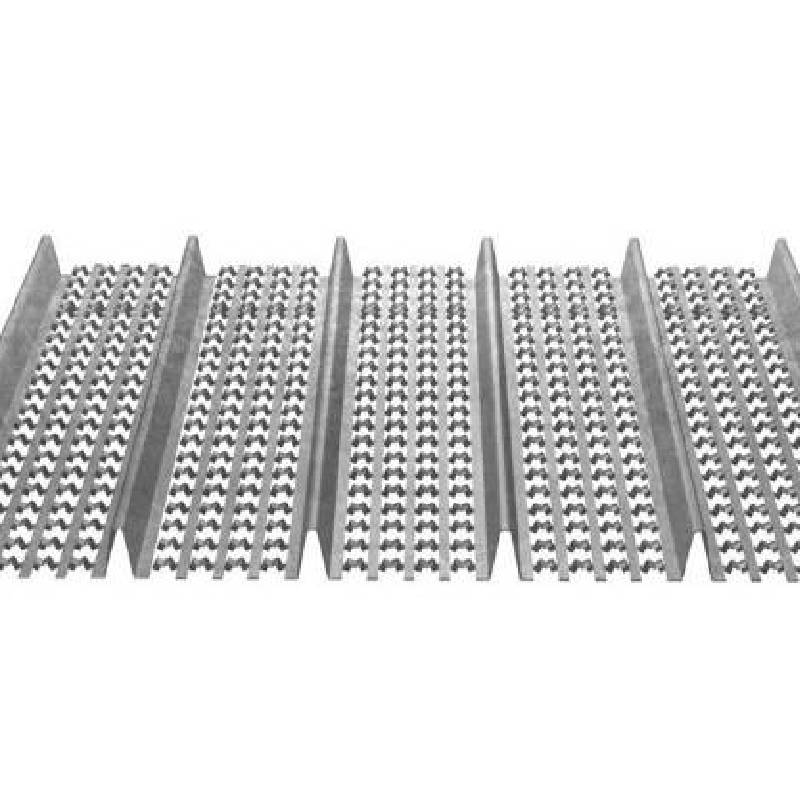

In addition to providing structural support, welded wire reinforcement can also improve the overall durability of the concrete. The steel wires are resistant to corrosion and provide an extra layer of protection against environmental factors such as moisture and temperature fluctuations

welded wire reinforcement for concrete. This can help extend the lifespan of the concrete and reduce the need for maintenance and repairs in the long run.

welded wire reinforcement for concrete. This can help extend the lifespan of the concrete and reduce the need for maintenance and repairs in the long run.