Current location:Home > hydraulic cylinder kits >

hydraulic cylinder kits

2025-08-14 13:24

2025-08-14 13:21

2025-08-14 12:24

2025-08-14 12:16

2025-08-14 12:16

...

2025-08-14 12:05

Once the cylinder is disassembled, the old seals can be removed by gently prying them out with a flat-bladed screwdriver or similar tool. It is important to handle the old seals carefully to avoid damaging them or the surrounding components. After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present

After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present replacing seals on a hydraulic cylinder. This will help to ensure that the new seals are installed in a clean and dry environment.

replacing seals on a hydraulic cylinder. This will help to ensure that the new seals are installed in a clean and dry environment.

After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present

After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present After removing the old seals, the cylinder should be thoroughly cleaned using a suitable solvent or cleaning solution to remove any dirt, debris, or residue that may be present replacing seals on a hydraulic cylinder. This will help to ensure that the new seals are installed in a clean and dry environment.

replacing seals on a hydraulic cylinder. This will help to ensure that the new seals are installed in a clean and dry environment.

...

2025-08-14 11:15

2025-08-14 11:12

2025-08-14 11:07

Proper maintenance of hub dust seals is essential for ensuring their effectiveness. Inspecting the seals regularly for signs of wear or damage, such as cracks or tears, can help prevent contaminants from infiltrating the wheel hub and causing damage to the bearings

hub dust seal. Additionally, ensuring that the seals are properly lubricated can help prolong their lifespan and maintain their functionality.

hub dust seal. Additionally, ensuring that the seals are properly lubricated can help prolong their lifespan and maintain their functionality.

...

2025-08-14 11:00

Latest articles

Installation of hydraulic piston seal kits requires precision and care hydraulic piston seal kit. Incorrect installation can lead to premature failure, leaks, or even system failure. It is advisable to follow manufacturer guidelines and use specialized tools to ensure accurate placement and avoid damage.

hydraulic piston seal kit. Incorrect installation can lead to premature failure, leaks, or even system failure. It is advisable to follow manufacturer guidelines and use specialized tools to ensure accurate placement and avoid damage.

hydraulic piston seal kit. Incorrect installation can lead to premature failure, leaks, or even system failure. It is advisable to follow manufacturer guidelines and use specialized tools to ensure accurate placement and avoid damage.

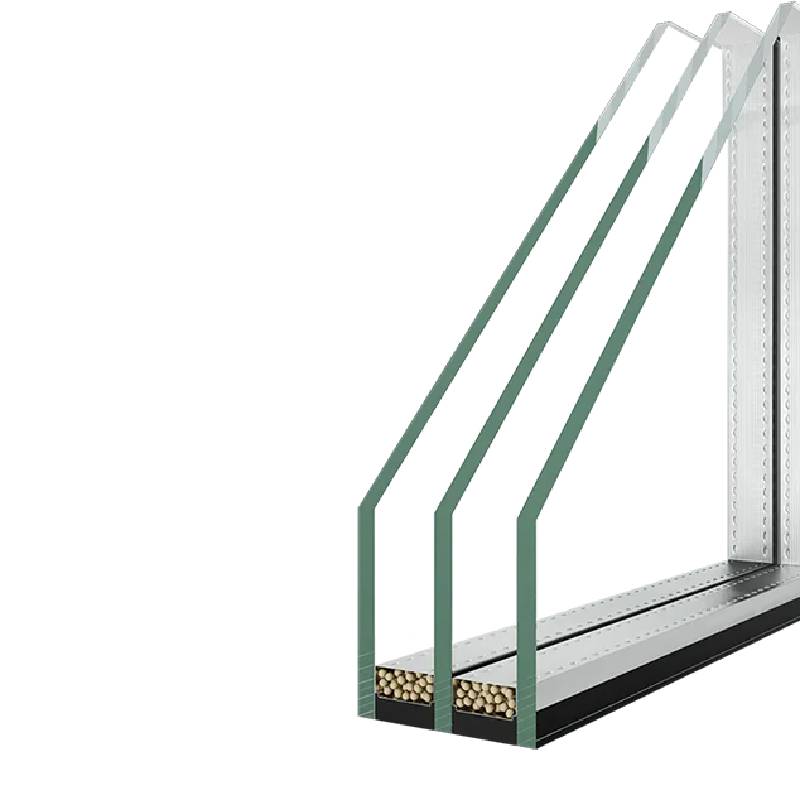

hydraulic piston seal kit. Incorrect installation can lead to premature failure, leaks, or even system failure. It is advisable to follow manufacturer guidelines and use specialized tools to ensure accurate placement and avoid damage.To combat slumping float glass sales, industry players need to adapt to changing market dynamics and consumer preferences slumping float glass. One possible strategy is to focus on niche markets where float glass still offers distinct advantages over alternative materials. For example, float glass is known for its optical clarity and scratch resistance, making it a preferred choice for high-end glass products such as mirrors, windows, and display cases.

slumping float glass. One possible strategy is to focus on niche markets where float glass still offers distinct advantages over alternative materials. For example, float glass is known for its optical clarity and scratch resistance, making it a preferred choice for high-end glass products such as mirrors, windows, and display cases.

slumping float glass. One possible strategy is to focus on niche markets where float glass still offers distinct advantages over alternative materials. For example, float glass is known for its optical clarity and scratch resistance, making it a preferred choice for high-end glass products such as mirrors, windows, and display cases.

slumping float glass. One possible strategy is to focus on niche markets where float glass still offers distinct advantages over alternative materials. For example, float glass is known for its optical clarity and scratch resistance, making it a preferred choice for high-end glass products such as mirrors, windows, and display cases.