Current location:Home > shaft seal wheel hub >

shaft seal wheel hub

2025-08-16 05:36

When a wheel bearing hub seal is compromised or damaged, it can lead to a host of problems for the vehicle. Dirt and water can infiltrate the wheel bearings, causing them to wear out prematurely and potentially leading to a dangerous situation on the road. The seal also plays a critical role in maintaining proper lubrication within the wheel assembly, ensuring that the bearings operate smoothly and efficiently.

...

2025-08-16 04:56

2025-08-16 04:52

2025-08-16 04:49

2025-08-16 04:37

2025-08-16 04:29

2025-08-16 04:11

2025-08-16 03:57

2025-08-16 03:51

2025-08-16 03:25

Latest articles

Once the old seal is removed, clean the area around the hub thoroughly to remove any dirt or debris

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

front hub seal. Install the new front hub seal by pressing it into place with a seal driver or a socket that is the same size as the seal. Make sure the seal is seated properly and is flush with the hub to ensure a tight seal.

Regular maintenance and inspection of oil seals are essential to ensure optimal performance and prevent potential leaks. Oil seals should be checked for wear and tear, cracks, or other signs of damage that could compromise their effectiveness. Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

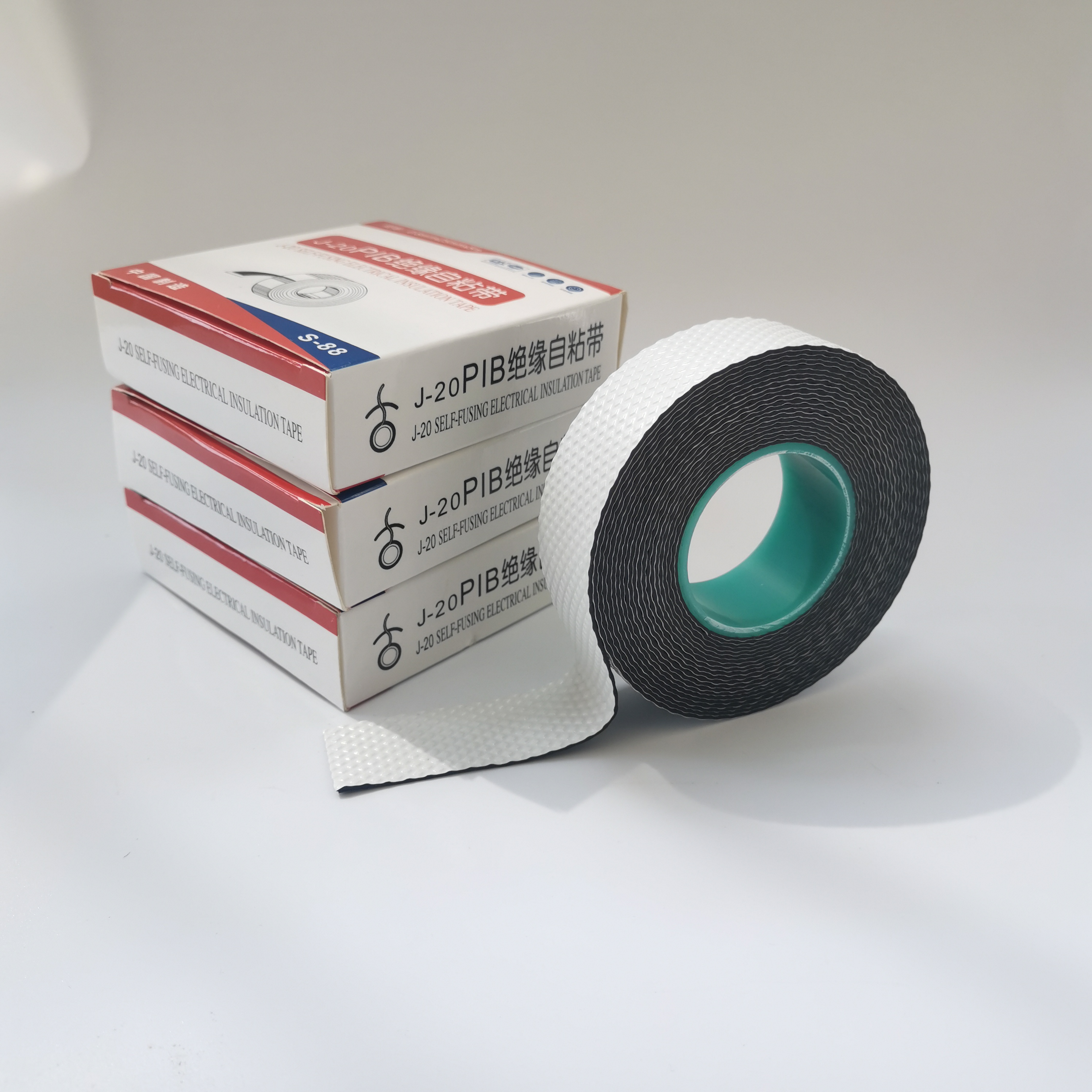

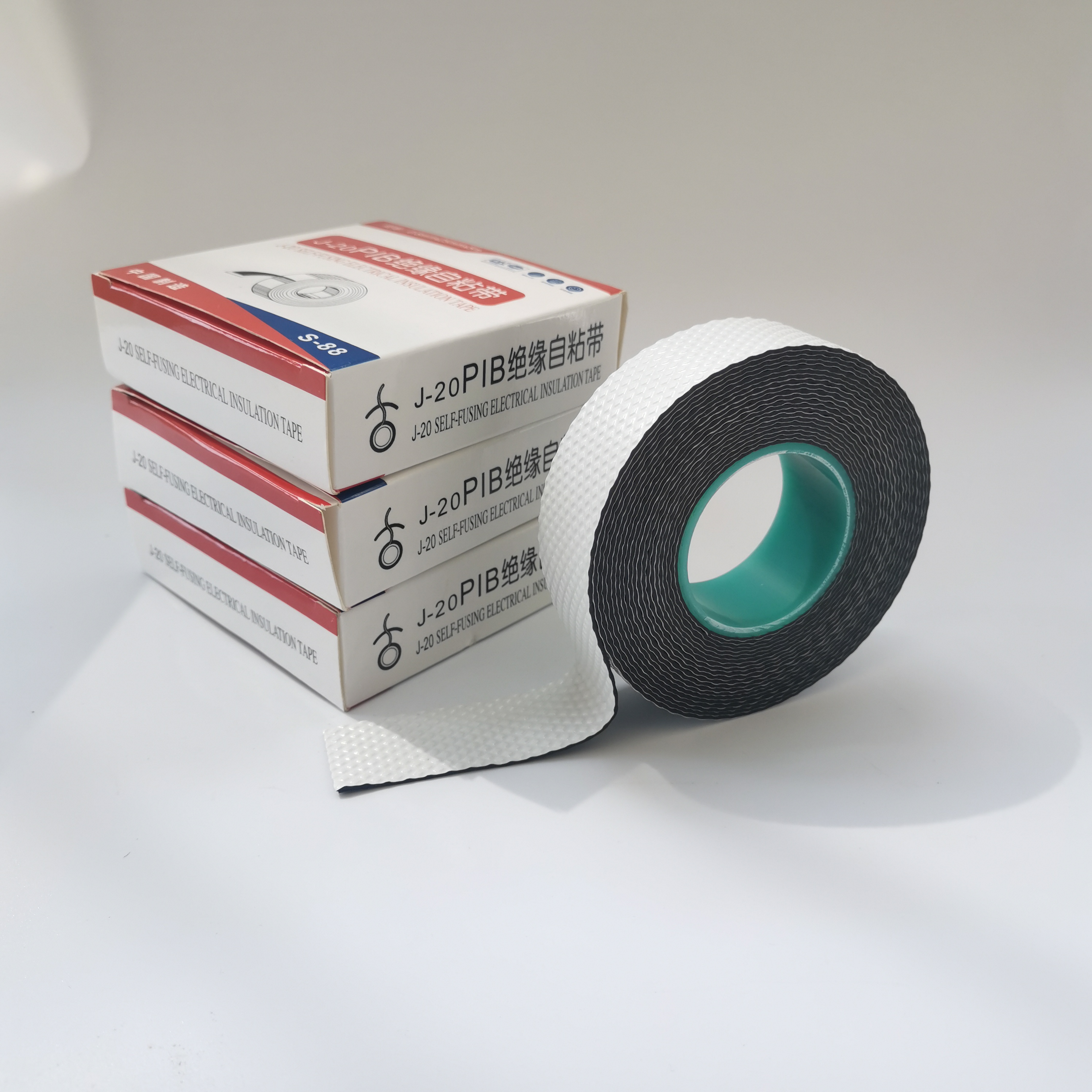

70 90 10 oil seal.2. Temperature Resistance High voltage installations often experience considerable heat. Insulation tape must be capable of operating under high temperatures while maintaining its insulating properties. Materials like PVC, silicone, and various rubber composites are commonly used for their heat-resistant qualities.

high voltage busbar insulation tape

Self-amalgamating tape can also be used for automotive repairs. It can be wrapped around hoses and pipes in the engine compartment to prevent leaks and ensure proper functioning of the vehicle

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.