Current location:Home > high pressure oil seals >

high pressure oil seals

2025-08-15 00:52

One of the key challenges in high-speed rotary shaft seals is managing heat generation. The friction caused by the seal's contact with the shaft can lead to significant heat build-up, potentially affecting the seal's integrity and lifespan. To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently high speed rotary shaft seals.

high speed rotary shaft seals.

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently high speed rotary shaft seals.

high speed rotary shaft seals.

...

2025-08-15 00:52

2025-08-15 00:50

2025-08-15 00:29

2025-08-15 00:23

2025-08-15 00:13

2025-08-14 23:05

2025-08-14 23:04

2025-08-14 22:40

Latest articles

Another benefit of the 20% 32% 6% oil seal is its ease of installation and compatibility with a wide range of machinery and equipment 20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.Next, we discuss the 40% figure, which can denote the allowable leakage rate for particular types of oil seals. Leakage can severely impact the overall performance of mechanical systems, leading to reduced lubrication and increased wear on components. A reputable oil seal must minimize leakage to a level that is often benchmarked at around 40% of the maximum allowable threshold for that system. Manufacturers pour significant resources into developing materials and designs that can achieve this standard, as minimizing leakage not only conserves lubricant but also enhances the efficiency and longevity of the machinery.

22 40 7 oil seal

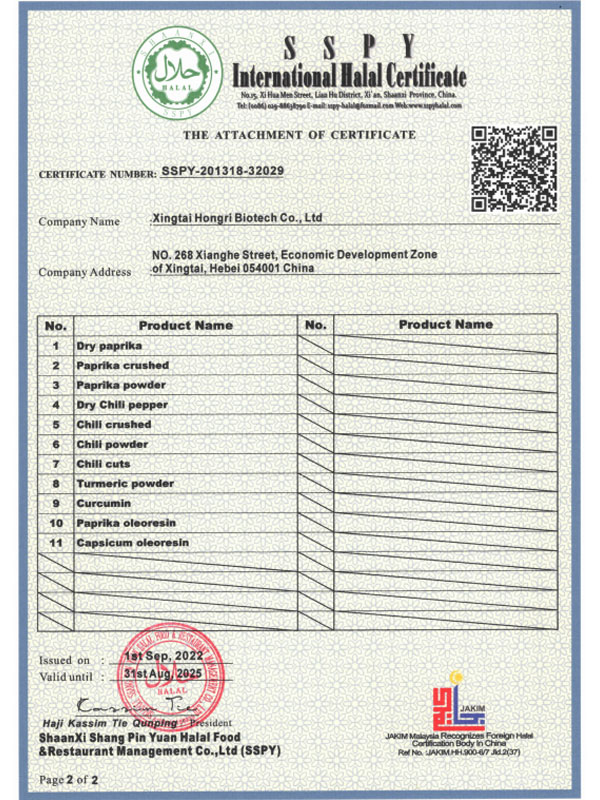

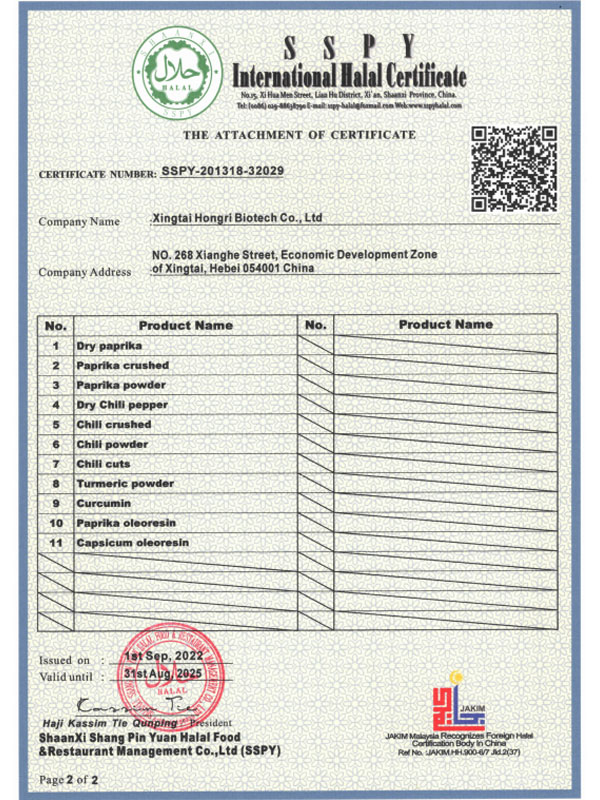

The drying process is followed by careful milling and sieving, ensuring a consistent texture and removing any seeds or stems. Some manufacturers even use traditional stone grinders to maintain the authentic flavor and aroma. The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product

The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product premium paprika manufacturers.

premium paprika manufacturers.

The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product

The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product The final step is often a meticulous sorting and packaging process to protect the freshness and integrity of the product premium paprika manufacturers.

premium paprika manufacturers.In addition to quality, it is also important to consider the variety of dried capsicum powder being offered by suppliers dried capsicum powder suppliers. While traditional red capsicum powder is the most common, some suppliers may also offer variations made from different types of peppers, such as jalapeno or habanero. This can provide consumers with a range of options to suit their individual taste preferences.

dried capsicum powder suppliers. While traditional red capsicum powder is the most common, some suppliers may also offer variations made from different types of peppers, such as jalapeno or habanero. This can provide consumers with a range of options to suit their individual taste preferences.

dried capsicum powder suppliers. While traditional red capsicum powder is the most common, some suppliers may also offer variations made from different types of peppers, such as jalapeno or habanero. This can provide consumers with a range of options to suit their individual taste preferences.

dried capsicum powder suppliers. While traditional red capsicum powder is the most common, some suppliers may also offer variations made from different types of peppers, such as jalapeno or habanero. This can provide consumers with a range of options to suit their individual taste preferences.