Current location:Home > 2 inch hydraulic cylinder seal kit >

2 inch hydraulic cylinder seal kit

2025-08-15 05:50

2025-08-15 05:46

2025-08-15 05:32

The 35x72x10 oil seal, with its specific dimensions, is designed to fit a shaft that measures 35 millimeters in diameter and 72 millimeters in length, with a thickness of 10 millimeters. This size is commonly used in a variety of small to medium-sized machines, such as pumps, motors, and gearboxes. The precise dimensions of the oil seal are crucial for ensuring a proper fit and a reliable seal that can withstand the operating conditions of the machine.

...

2025-08-15 05:32

Once the old seals are out, the cylinder should be thoroughly cleaned to remove any debris or residual oil that could interfere with the new seals' performance. Inspecting the cylinder for damage, such as scoring or scratches, is also critical at this stage. If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals

If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals replacing seals hydraulic cylinder.

replacing seals hydraulic cylinder.

If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals

If any issues are found, they need to be addressed before installing new seals If any issues are found, they need to be addressed before installing new seals replacing seals hydraulic cylinder.

replacing seals hydraulic cylinder.

...

2025-08-15 05:13

2025-08-15 04:25

2025-08-15 04:12

2025-08-15 03:47

2025-08-15 03:42

2025-08-15 03:31

Latest articles

In manufacturing equipment, where heavy machinery is common, the 25% 2035 7 oil seal helps to contain fluids and prevent contaminants from entering systems. This is particularly important in hydraulic applications, where the integrity of the hydraulic fluid must be maintained for effective operation. Similarly, in construction machinery, the seal plays a vital role in ensuring that heavy equipment operates smoothly, reducing maintenance costs due to leaks and failures.

25 35 7 oil seal

Internal pipe couplings are also versatile in their application, as they can be used to connect pipes of different materials, sizes, and configurations. This flexibility makes them a valuable tool for pipeline construction projects where various pipe sizes and materials are used

internal pipe coupling. Additionally, internal pipe couplings are easy to install and require minimal maintenance, making them a cost-effective solution for pipeline repairs and upgrades.

internal pipe coupling. Additionally, internal pipe couplings are easy to install and require minimal maintenance, making them a cost-effective solution for pipeline repairs and upgrades.

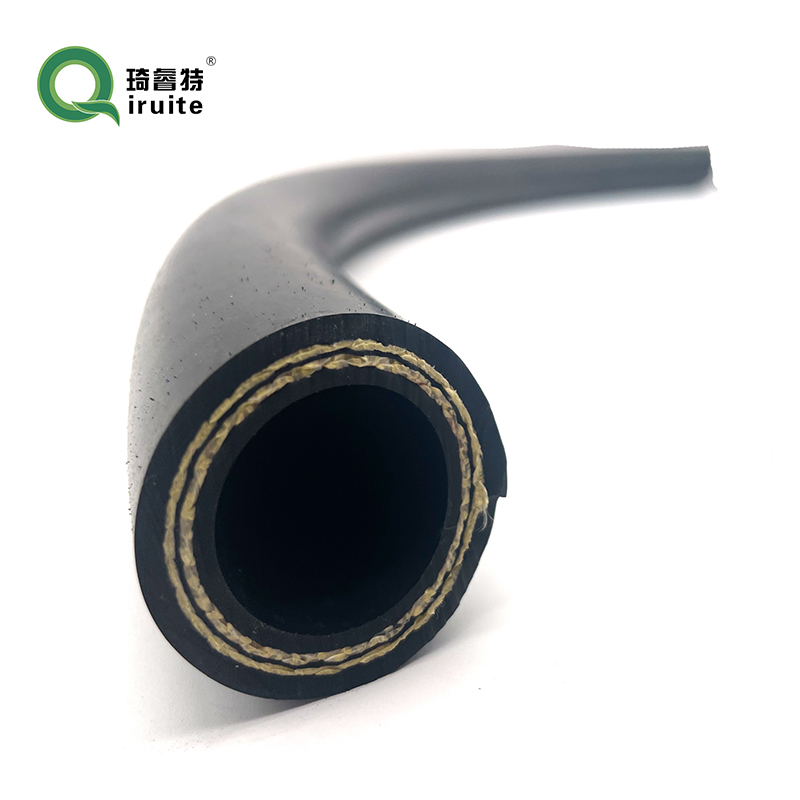

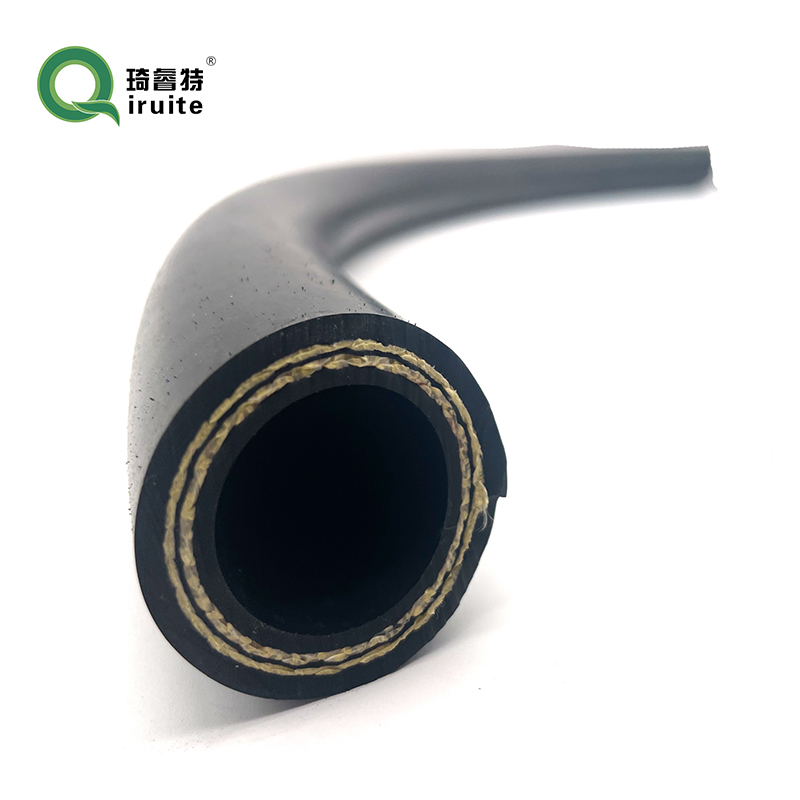

After selecting the new hose, prepare the area for installation by cleaning the connection points and applying a small amount of clean engine oil to the hose fittings power steering hose repair. This will help create a seal and prevent leaks. Carefully slide the new hose onto the power steering pump and steering gear connections, making sure it is securely in place.

power steering hose repair. This will help create a seal and prevent leaks. Carefully slide the new hose onto the power steering pump and steering gear connections, making sure it is securely in place.

power steering hose repair. This will help create a seal and prevent leaks. Carefully slide the new hose onto the power steering pump and steering gear connections, making sure it is securely in place.

power steering hose repair. This will help create a seal and prevent leaks. Carefully slide the new hose onto the power steering pump and steering gear connections, making sure it is securely in place.