Current location:Home > 40x55x8 oil seal >

40x55x8 oil seal

2025-08-14 07:57

2025-08-14 07:22

2025-08-14 07:14

2025-08-14 07:02

2025-08-14 06:54

2025-08-14 06:40

2025-08-14 06:29

2025-08-14 06:25

2025-08-14 06:07

2025-08-14 05:55

Latest articles

Another important consideration when selecting an oil seal is its design. Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements

Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements 22 35 7 oil seal. For example, lip seals are commonly used in applications where the shaft has a small diameter, while radial shaft seals are better suited for larger diameters. Additionally, the design of the seal's sealing lip can vary, with some being more effective at creating a tight seal under high pressure or speed conditions.

22 35 7 oil seal. For example, lip seals are commonly used in applications where the shaft has a small diameter, while radial shaft seals are better suited for larger diameters. Additionally, the design of the seal's sealing lip can vary, with some being more effective at creating a tight seal under high pressure or speed conditions.

Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements

Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements Oil seals come in a variety of shapes and sizes, each designed to meet specific requirements 22 35 7 oil seal. For example, lip seals are commonly used in applications where the shaft has a small diameter, while radial shaft seals are better suited for larger diameters. Additionally, the design of the seal's sealing lip can vary, with some being more effective at creating a tight seal under high pressure or speed conditions.

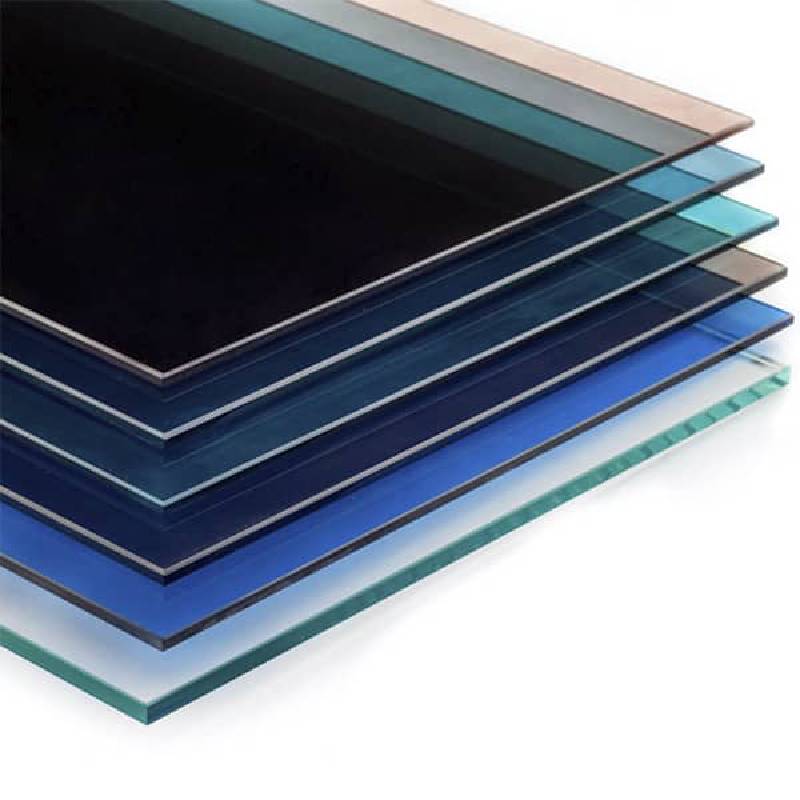

22 35 7 oil seal. For example, lip seals are commonly used in applications where the shaft has a small diameter, while radial shaft seals are better suited for larger diameters. Additionally, the design of the seal's sealing lip can vary, with some being more effective at creating a tight seal under high pressure or speed conditions.Moreover, low e-glass panes offer protection against UV rays, which are known to cause furniture fading and can potentially harm skin low e glass panes. The coating not only blocks heat but also filters out harmful ultraviolet radiation, preserving the interior’s aesthetics and inhabitants' health.

low e glass panes. The coating not only blocks heat but also filters out harmful ultraviolet radiation, preserving the interior’s aesthetics and inhabitants' health.

low e glass panes. The coating not only blocks heat but also filters out harmful ultraviolet radiation, preserving the interior’s aesthetics and inhabitants' health.

low e glass panes. The coating not only blocks heat but also filters out harmful ultraviolet radiation, preserving the interior’s aesthetics and inhabitants' health.In addition to its privacy-enhancing properties, frosted opaque glass also has a decorative appeal. The textured surface of the glass can add visual interest to a space, creating a soft, diffused look that complements a variety of design styles. Frosted opaque glass can be used to create a modern, minimalist aesthetic or to add a touch of elegance to a traditional space.

The first step in the tempering process is to heat the float glass. This is done using a gas-fired furnace or an electric furnace. The furnace temperature is carefully controlled to avoid any melting or deformation of the glass. Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber float glass tempered.

float glass tempered.

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber float glass tempered.

float glass tempered.As explained in the video, float glass possesses a number of key attributes that make it highly desirable for use in windows, glass facades, and more. Its exceptional clarity is one of its hallmark features, allowing for maximum light transmission while minimizing distortion. Furthermore, float glass can be produced in a variety of thicknesses and sizes, making it adaptable for numerous applications.

float glass video