Current location:Home > tcn oil seal >

tcn oil seal

2025-08-14 18:25

2025-08-14 17:27

2025-08-14 17:26

2025-08-14 17:20

2025-08-14 17:12

2025-08-14 17:00

2025-08-14 16:52

2025-08-14 16:15

...

2025-08-14 16:08

2025-08-14 15:59

Latest articles

The selection of a seal kit for a cylinder depends on several factors, such as the type and size of the cylinder, the operating conditions, and the type of fluid used. Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance

Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance seal kit for cylinder. Therefore, it's vital to consult the manufacturer's specifications before purchasing a seal kit.

seal kit for cylinder. Therefore, it's vital to consult the manufacturer's specifications before purchasing a seal kit.

Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance

Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance Compatibility is crucial, as using the wrong kit can lead to premature failure or inefficient performance seal kit for cylinder. Therefore, it's vital to consult the manufacturer's specifications before purchasing a seal kit.

seal kit for cylinder. Therefore, it's vital to consult the manufacturer's specifications before purchasing a seal kit.Regular monitoring and changing of pump seal oil is necessary to maintain its effectiveness pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.

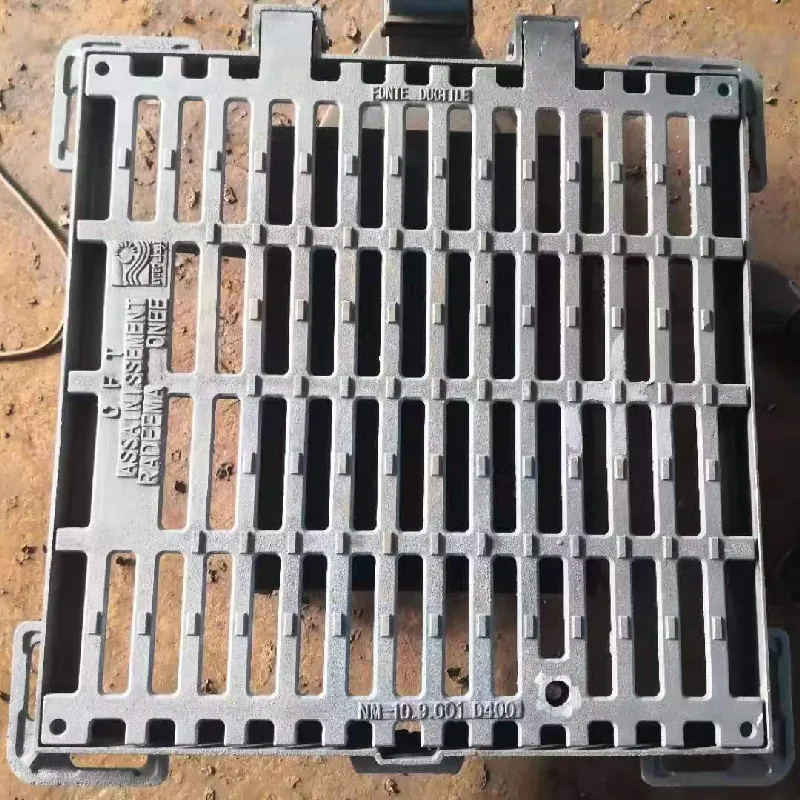

pump seal oil. As the oil degrades over time, it can lose its lubricating properties and become contaminated with debris from the pumped fluid. This can cause the seal to fail prematurely, leading to leaks and other issues. Therefore, it is important to check the oil level regularly and change it according to the manufacturer's recommendations.Another significant advantage of ductile iron covers and frames is their resistance to corrosion. Urban environments expose infrastructure to various corrosive elements, including chemicals from roadways, saline environments, and environmental pollutants. Ductile iron can be coated with protective finishes, such as asphalt or epoxy, to further enhance its corrosion resistance. This quality extends the life of the product substantially, reducing the need for frequent repairs or replacements and thereby resulting in cost savings for municipalities and contractors.

ductile iron cover and frame