Current location:Home > Hebei Hankai oil seals >

Hebei Hankai oil seals

...

2025-08-14 07:16

In terms of effectiveness, both dust seals and oil seals are important for protecting machinery and equipment. Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

...

2025-08-14 07:03

2025-08-14 07:00

2025-08-14 06:31

2025-08-14 05:46

2025-08-14 05:41

2025-08-14 05:40

2025-08-14 05:24

2025-08-14 05:01

2025-08-14 04:57

Latest articles

Moreover, the single lip oil seal's construction ensures durability and reliability. The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear

The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear single lip oil seal. The metal case adds strength and stability, while the spring maintains consistent contact pressure, ensuring a reliable seal even under varying operating conditions.

single lip oil seal. The metal case adds strength and stability, while the spring maintains consistent contact pressure, ensuring a reliable seal even under varying operating conditions.

The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear

The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear The elastomeric material provides flexibility and resilience, enabling it to withstand temperature fluctuations and resist wear and tear single lip oil seal. The metal case adds strength and stability, while the spring maintains consistent contact pressure, ensuring a reliable seal even under varying operating conditions.

single lip oil seal. The metal case adds strength and stability, while the spring maintains consistent contact pressure, ensuring a reliable seal even under varying operating conditions.Over time, the wheel bearing hub seal can wear out and become damaged, leading to leaks and potential contamination of the wheel bearings. Signs that the wheel bearing hub seal may be failing include squeaking or grinding noises coming from the wheels, uneven tire wear, and vibrations in the steering wheel.

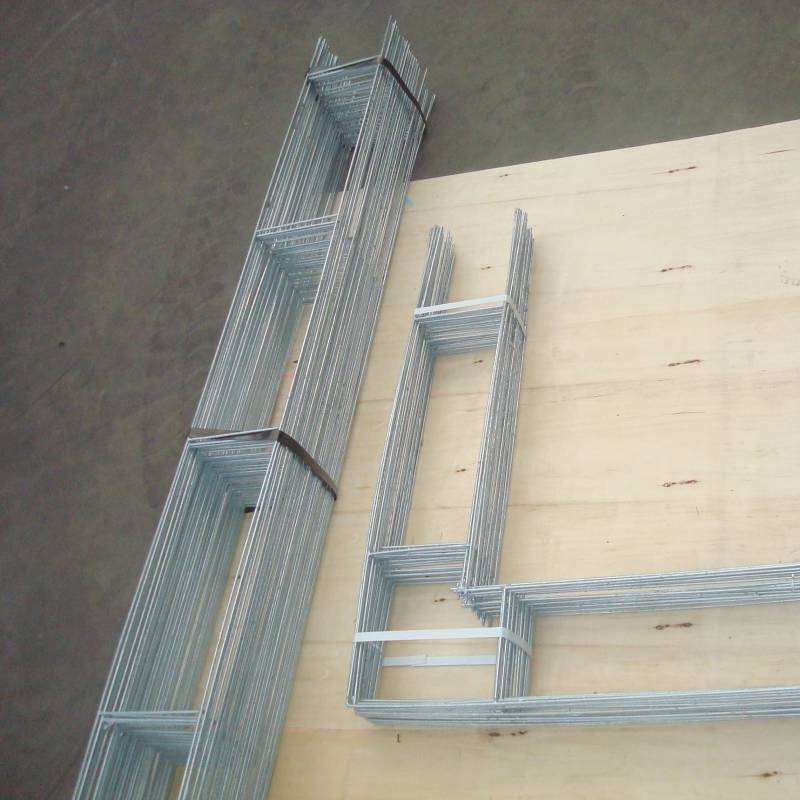

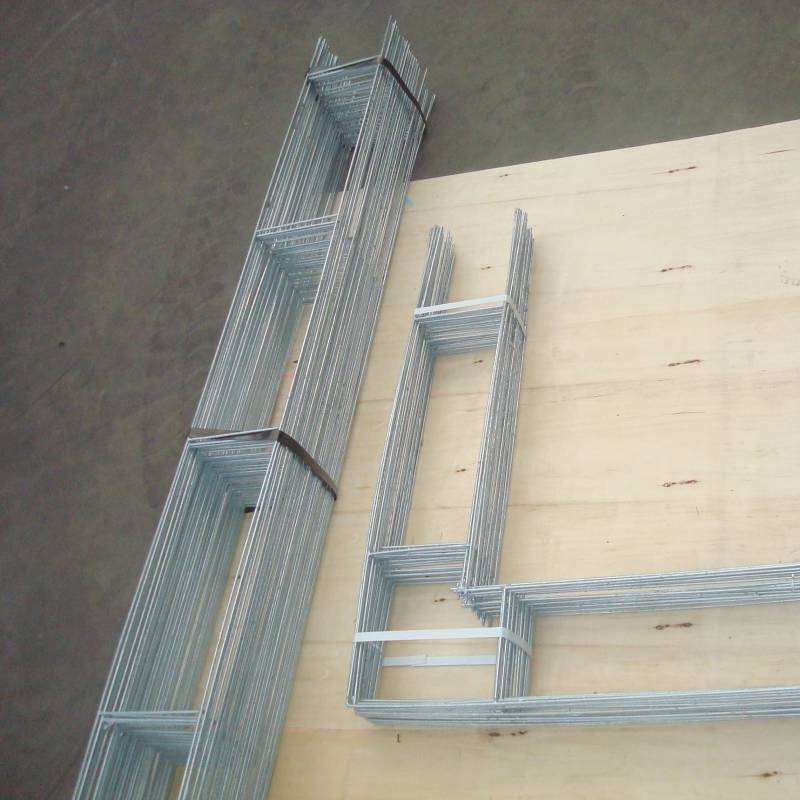

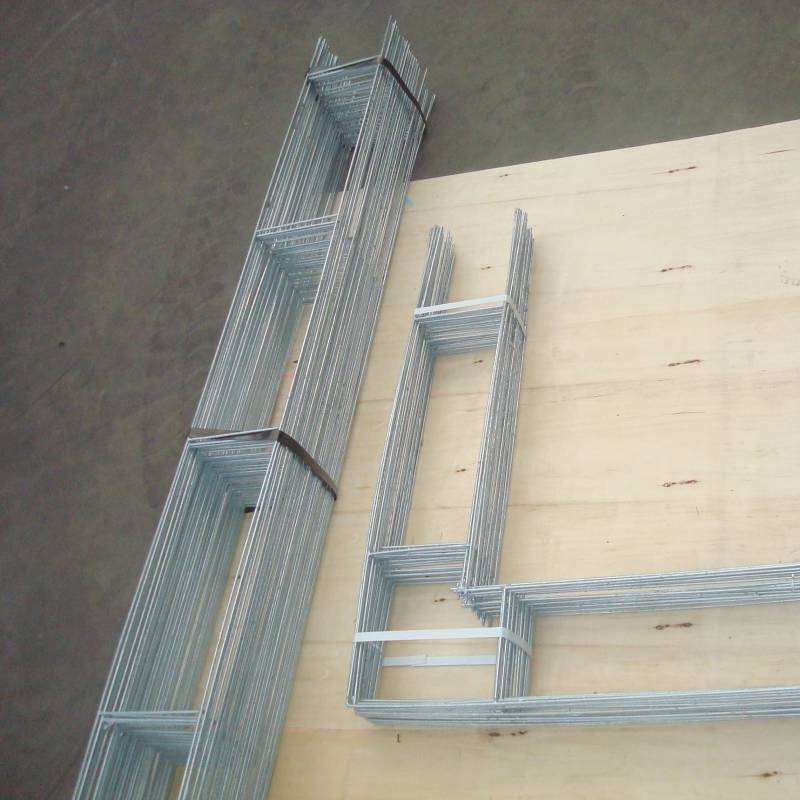

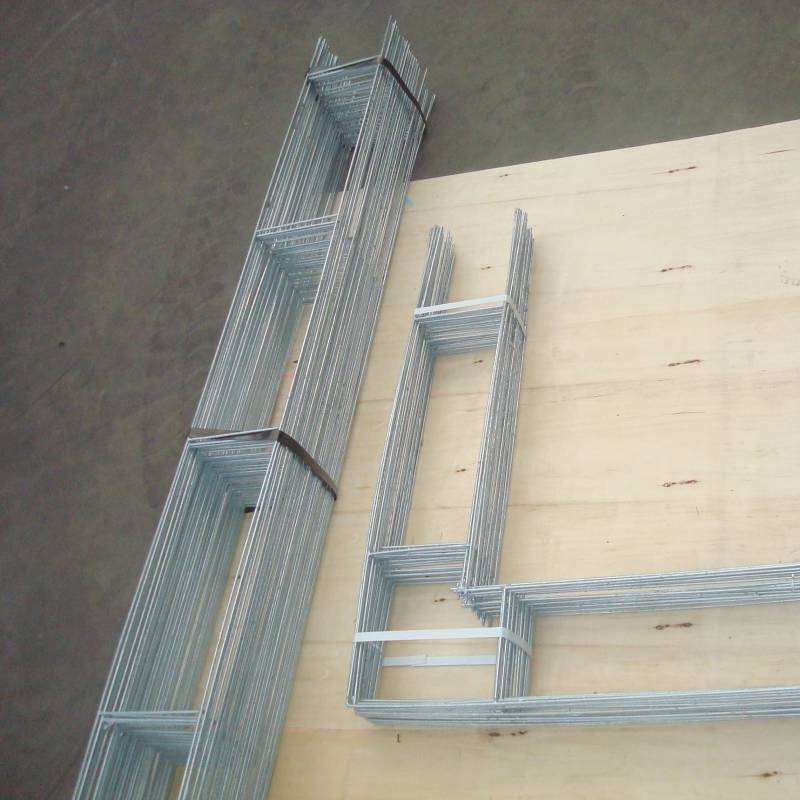

There are various types of tomato cages available on the market, ranging from simple wire cages to more elaborate designs made of heavy-duty materials

strong tomato cages. When choosing a tomato cage, it is important to select one that is sturdy and durable enough to withstand the weight of a fully grown tomato plant. Look for cages made of high-quality materials such as galvanized steel or heavy-duty plastic, as these will provide the necessary support and stability for your plants.

strong tomato cages. When choosing a tomato cage, it is important to select one that is sturdy and durable enough to withstand the weight of a fully grown tomato plant. Look for cages made of high-quality materials such as galvanized steel or heavy-duty plastic, as these will provide the necessary support and stability for your plants.

Moreover, these springs offer a unique advantage due to their space-saving design. Their compact size allows them to be integrated into tight spaces, making them ideal for applications where space is at a premium. Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment

Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment utility extension spring.

utility extension spring.

Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment

Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment Their efficiency in utilizing available space, combined with their capacity to generate and control force, makes them a valuable utility extension in machinery and equipment utility extension spring.

utility extension spring.The length and width of the roll also contribute to the overall cost. Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices chicken wire price. Larger rolls generally offer a more cost-effective option per square foot.

chicken wire price. Larger rolls generally offer a more cost-effective option per square foot.

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices chicken wire price. Larger rolls generally offer a more cost-effective option per square foot.

chicken wire price. Larger rolls generally offer a more cost-effective option per square foot.