Current location:Home > oil hub seal >

oil hub seal

2025-08-14 09:33

Additionally, the 22% 40% 7% oil seal is designed for long-lasting performance, with a high resistance to wear and tear

22 40 7 oil seal. This oil seal is built to withstand the demands of continuous use and heavy loads, making it a reliable choice for equipment that operates in challenging environments. The durability of the 22% 40% 7% oil seal ensures that it can provide effective sealing for an extended period, reducing the need for frequent replacements and maintenance.

22 40 7 oil seal. This oil seal is built to withstand the demands of continuous use and heavy loads, making it a reliable choice for equipment that operates in challenging environments. The durability of the 22% 40% 7% oil seal ensures that it can provide effective sealing for an extended period, reducing the need for frequent replacements and maintenance.

...

2025-08-14 08:56

...

2025-08-14 08:53

2025-08-14 08:49

2025-08-14 08:37

2025-08-14 08:36

2025-08-14 07:54

2025-08-14 07:42

2025-08-14 07:14

The design of the tilt cylinder seal kit takes into account the rigorous demands placed on these seals in dynamic and often harsh environments. Materials used for manufacturing these seals are carefully selected for their durability, resistance to temperature extremes, and compatibility with various types of hydraulic fluids. Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

tilt cylinder seal kit.

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

tilt cylinder seal kit.

...

2025-08-14 06:53

Latest articles

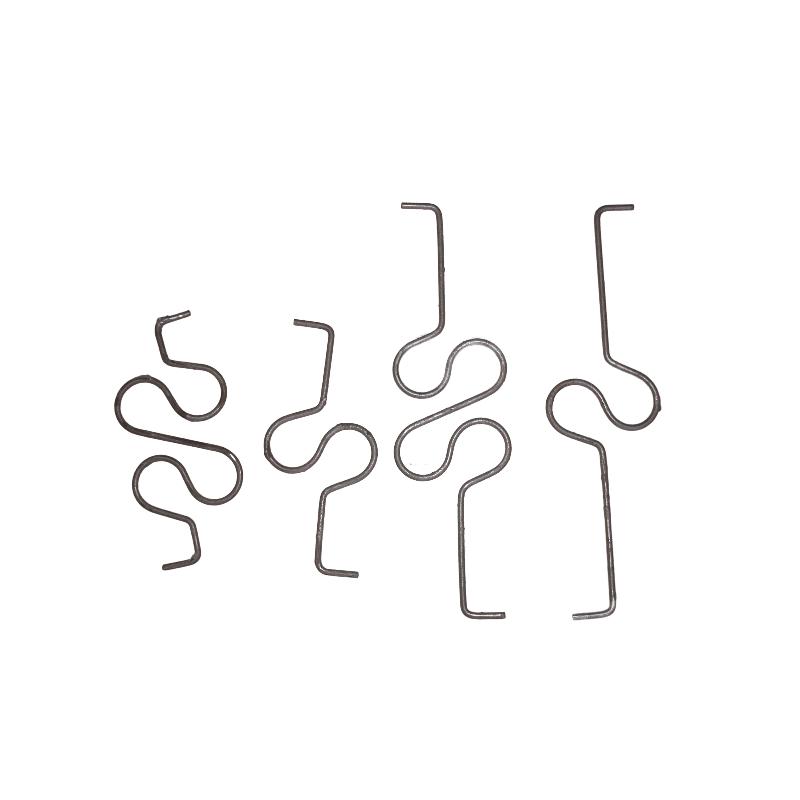

Innovations in materials science have also influenced the development of heavy duty brick ties heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure.

heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure.

heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure.

heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure.