hydraulic cylinder oil seal

This is particularly vital in high-speed rotating equipment such as pumps, motors, and gearboxes, where the slightest leak could lead to severe damage or even complete system failure This is particularly vital in high-speed rotating equipment such as pumps, motors, and gearboxes, where the slightest leak could lead to severe damage or even complete system failure

This is particularly vital in high-speed rotating equipment such as pumps, motors, and gearboxes, where the slightest leak could lead to severe damage or even complete system failure This is particularly vital in high-speed rotating equipment such as pumps, motors, and gearboxes, where the slightest leak could lead to severe damage or even complete system failure 12x22x5 oil seal.

12x22x5 oil seal.

custom made oil seals. While off-the-shelf seals may be readily available, they may not always provide the perfect fit for specialized equipment. Custom-made seals are designed to match the exact specifications of the application, reducing the need for costly modifications or replacements in the future. This helps in minimizing downtime and maintenance costs, ultimately leading to enhanced productivity and profitability for businesses.

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.

25 47 7 oil seal.

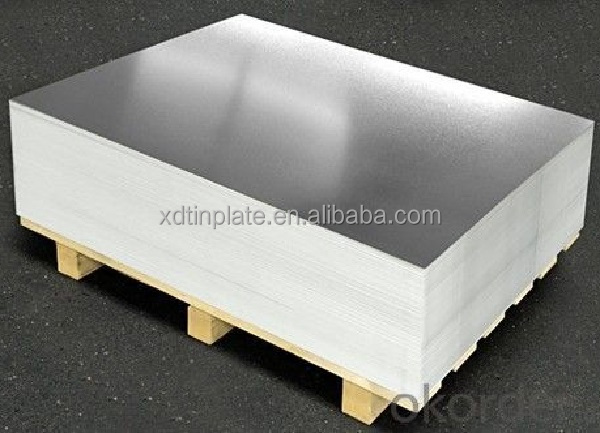

2. Sustainability Practices In today’s eco-conscious market, sustainability is more than just a trend; it’s a necessity. Suppliers who implement sustainable practices in their manufacturing processes, such as recycling scrap metal and reducing waste, can add value to a business’s commitment to environmental responsibility.

tin plate factory suppliers

Quality assurance is a critical aspect of the production of malleable iron galvanized pipe fittings. Most factories implement stringent quality control measures to ensure that every product meets industry standards. This includes dimensional inspections, pressure testing, and surface quality evaluations. Compliance with international standards, such as ISO and ASTM, further reinforces the reliability and safety of these fittings in piping systems.

malleable iron galvanized pipe fittings factories