Current location:Home > white hydraulic motor seal kit >

white hydraulic motor seal kit

2025-08-15 22:31

2025-08-15 22:25

2025-08-15 22:18

2025-08-15 22:04

2025-08-15 21:46

2025-08-15 21:37

2025-08-15 21:14

Next, we discuss the 40% figure, which can denote the allowable leakage rate for particular types of oil seals. Leakage can severely impact the overall performance of mechanical systems, leading to reduced lubrication and increased wear on components. A reputable oil seal must minimize leakage to a level that is often benchmarked at around 40% of the maximum allowable threshold for that system. Manufacturers pour significant resources into developing materials and designs that can achieve this standard, as minimizing leakage not only conserves lubricant but also enhances the efficiency and longevity of the machinery.

22 40 7 oil seal

...

2025-08-15 20:45

2025-08-15 20:37

2025-08-15 20:32

Latest articles

The selection of the right hydraulic cylinder seal kit is critical. Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered

Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered hydraulic cylinder seal kits. High-quality seals, often made from materials like polyurethane, rubber, or PTFE, can withstand harsh environments and resist degradation over time.

hydraulic cylinder seal kits. High-quality seals, often made from materials like polyurethane, rubber, or PTFE, can withstand harsh environments and resist degradation over time.

Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered

Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered Factors such as operating pressure, temperature, fluid compatibility, and cylinder speed must be considered hydraulic cylinder seal kits. High-quality seals, often made from materials like polyurethane, rubber, or PTFE, can withstand harsh environments and resist degradation over time.

hydraulic cylinder seal kits. High-quality seals, often made from materials like polyurethane, rubber, or PTFE, can withstand harsh environments and resist degradation over time.In addition to preventing the ingress of contaminants, dust lip seals also play a role in retaining lubricants within the system. Lubricants such as oil and grease are essential for reducing friction and wear between moving parts, helping to extend the lifespan of the equipment. Without an effective seal in place, these lubricants can leak out of the system, leading to insufficient lubrication and potential damage to the machinery. Dust lip seals help to maintain the proper levels of lubricant within the system, ensuring optimal performance and minimizing the risk of failure.

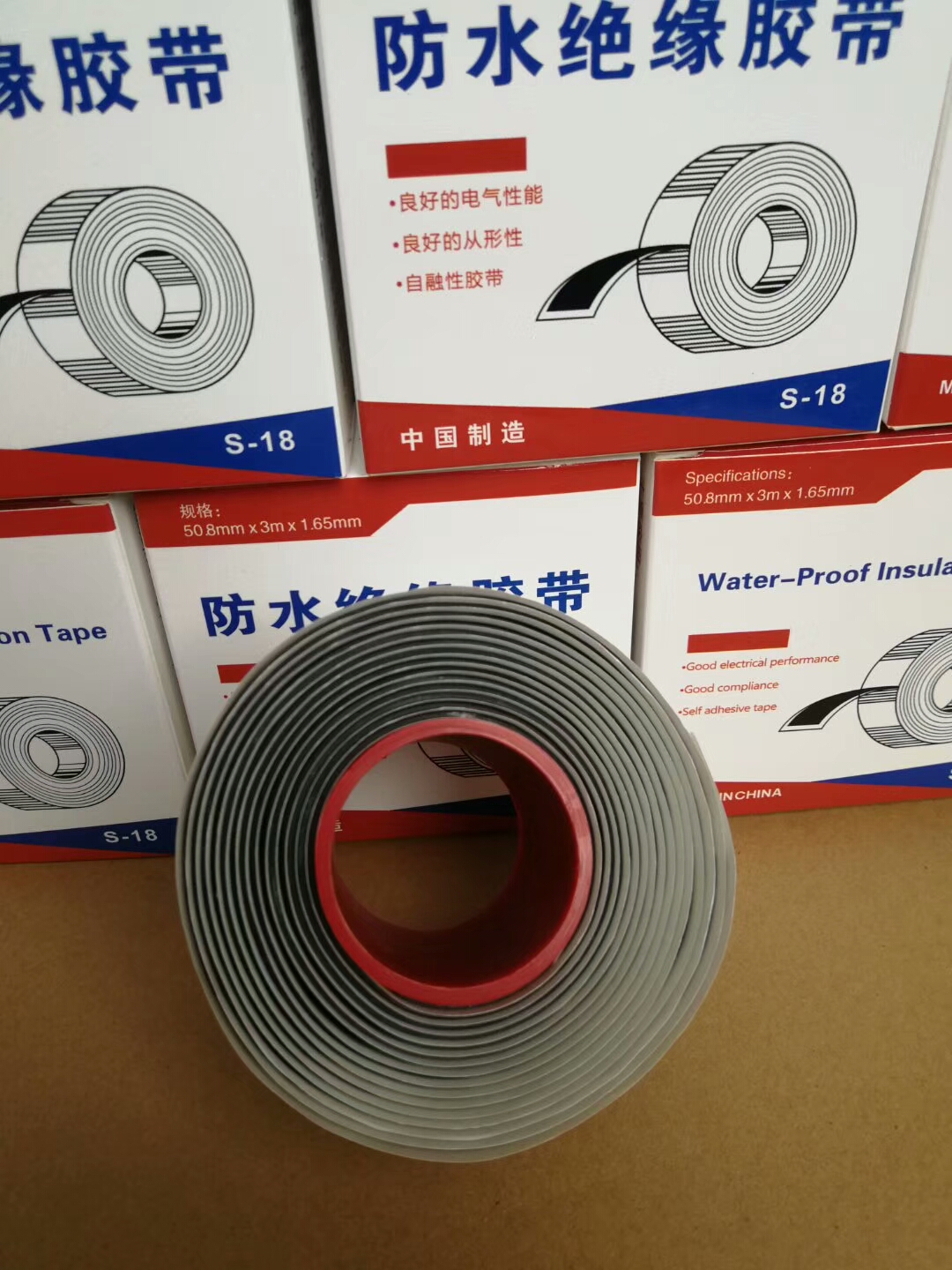

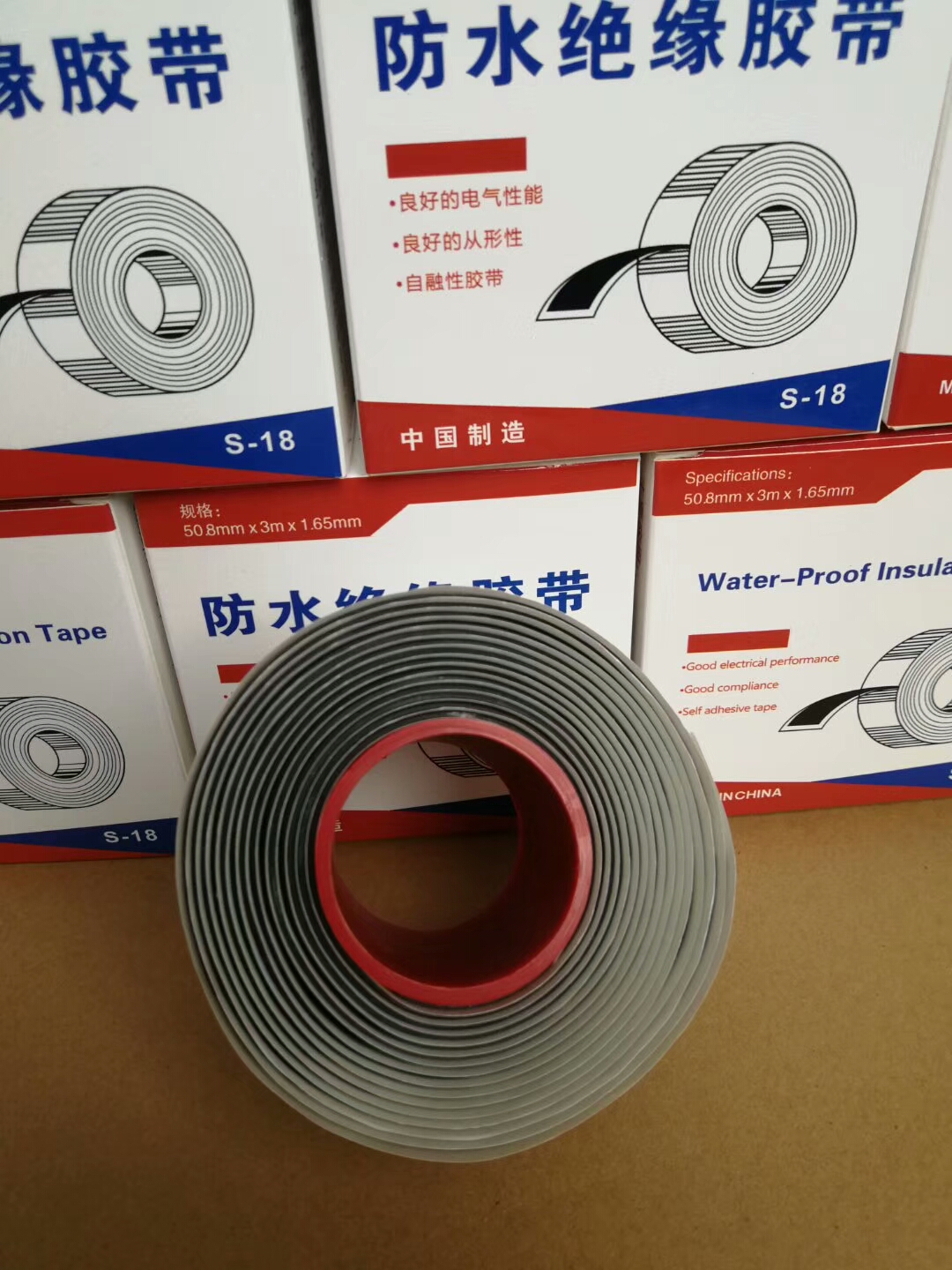

In the printing industry, splicing tape is used to join the ends of rolls of paper or other substrates in order to create a seamless feed for printing presses

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.