Current location:Home > oil seal suppliers >

oil seal suppliers

2025-08-15 06:41

2025-08-15 06:11

2025-08-15 06:02

2025-08-15 05:58

2025-08-15 05:57

2025-08-15 05:48

2025-08-15 05:37

2025-08-15 05:33

2025-08-15 05:05

2025-08-15 04:48

Latest articles

Rotary oil seals come in a variety of designs and materials to suit different applications and operating conditions rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation.

rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation.

rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation.

rotary oil seals. Common types of rotary seals include lip seals, labyrinth seals, and mechanical seals, each offering specific advantages in terms of sealing efficiency, durability, and resistance to high temperatures and pressures. The choice of seal depends on factors such as the speed of rotation, the type of fluid being sealed, and the temperature and pressure conditions of the operation.For example, nitrile rubber oil seals are commonly used in automotive applications due to their durability and resistance to oil and grease. Silicone rubber oil seals are preferred for applications that require high temperatures, as they can withstand temperatures up to 400 degrees Fahrenheit. Polyacrylate oil seals are known for their resistance to heat, oil, and chemicals, making them ideal for more demanding industrial applications.

One of the key advantages of the oil seal TCV is its ability to provide triple protection against oil leakage. The three sealing lips work together to create multiple barriers that effectively prevent fluid from escaping the system. This is especially important in high-speed or high-pressure applications where even a small amount of leakage can result in significant performance issues or even damage to the machinery.

Another important function of a dust seal is to prevent leakage of hydraulic fluid. If dust and dirt particles are allowed to enter the cylinder, they can create small gaps and openings that allow fluid to escape

hydraulic cylinder dust seal. This can result in a loss of pressure and reduced performance of the hydraulic system. Dust seals help maintain the integrity of the cylinder by sealing off any potential entry points for contaminants, preventing leaks and ensuring the proper functioning of the system.

hydraulic cylinder dust seal. This can result in a loss of pressure and reduced performance of the hydraulic system. Dust seals help maintain the integrity of the cylinder by sealing off any potential entry points for contaminants, preventing leaks and ensuring the proper functioning of the system.

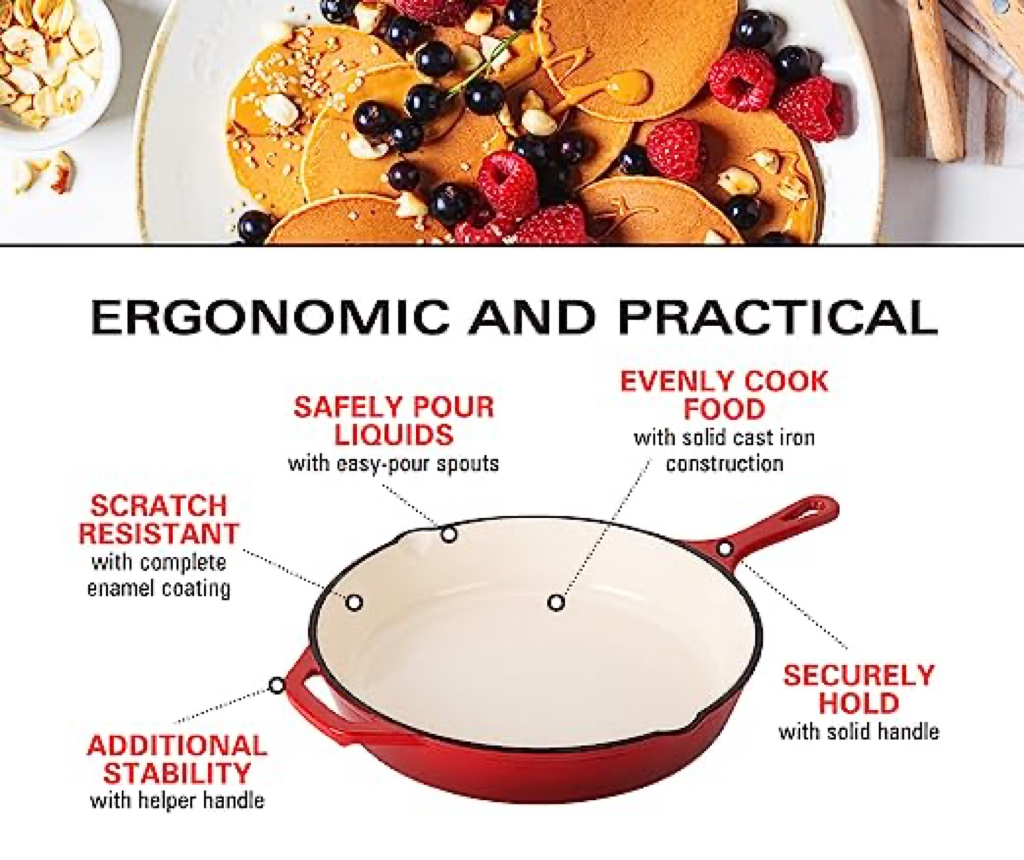

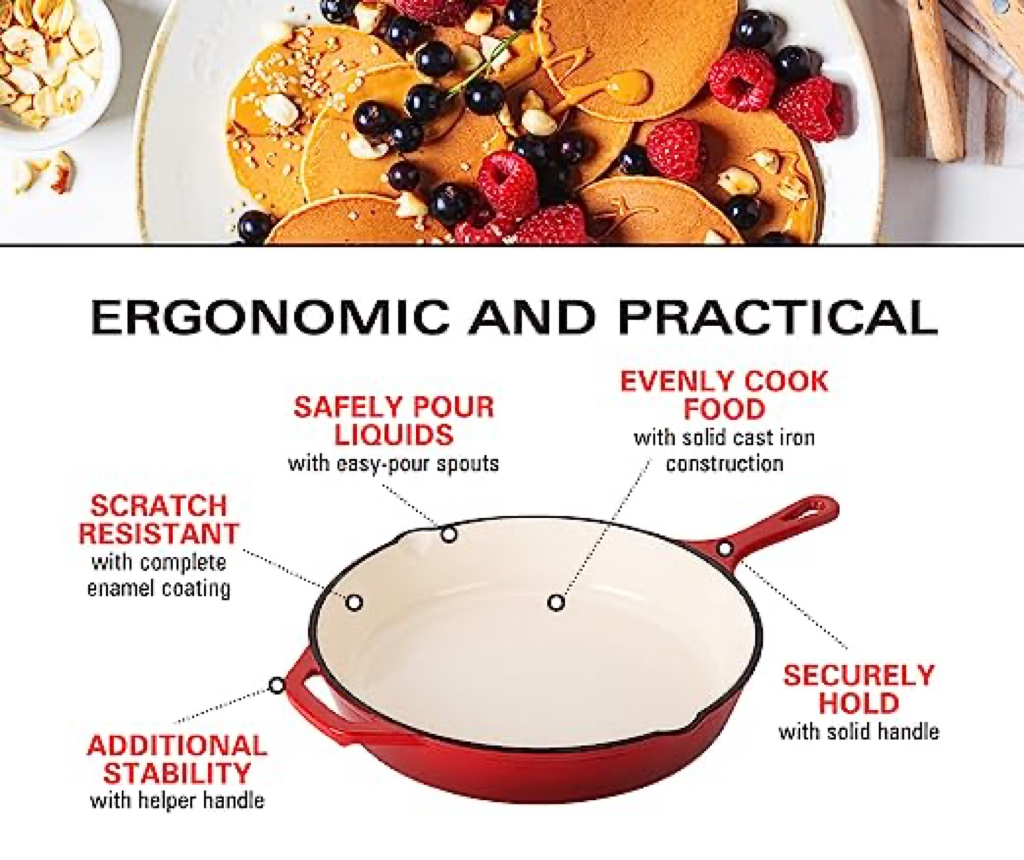

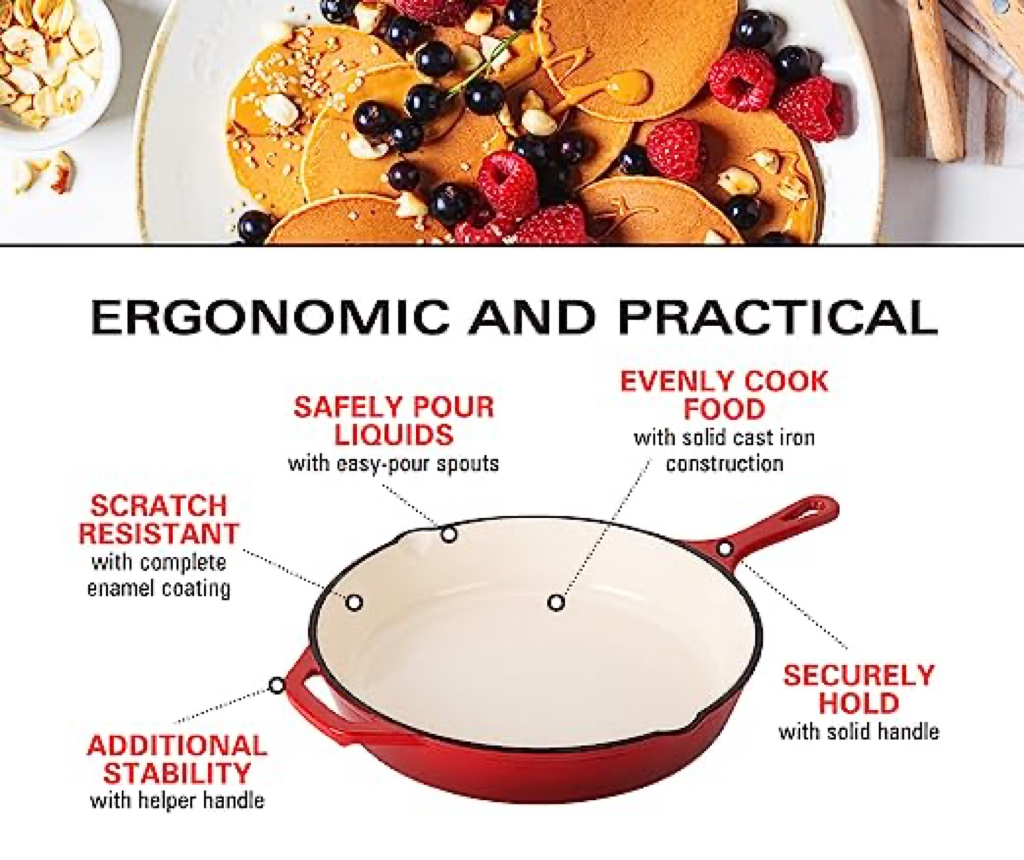

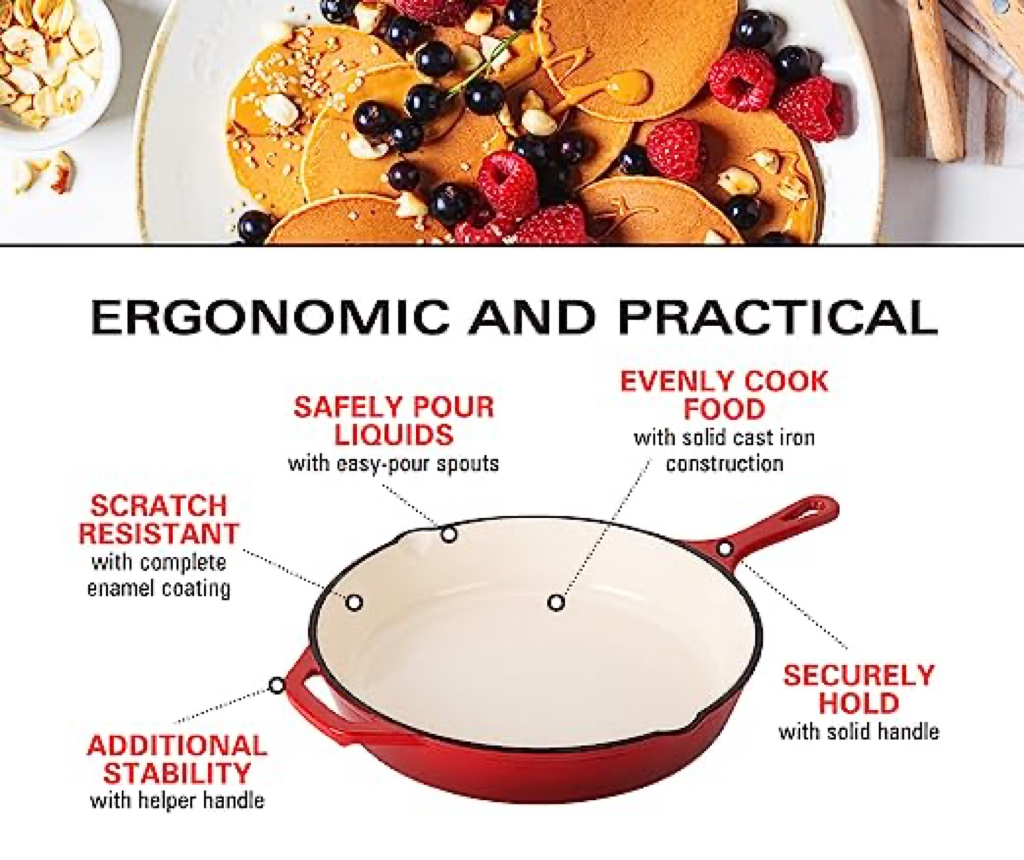

In addition to its superior heat retention, a flat iron skillet pan is also incredibly versatile. You can use it on the stovetop, in the oven, or even on the grill. This versatility makes it a great option for a wide range of recipes, from sautéed vegetables to skillet cookies. The high sides of the pan also make it perfect for simmering sauces and soups, adding to its versatility in the kitchen

flat iron skillet pan.

flat iron skillet pan.

Cleaning a ribbed grill pan can sometimes be a challenge due to its grooved surface, which may trap food particles. However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed

However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed ribbed grill pan. Soaking the pan in warm, soapy water after use can help loosen any stubborn bits, while regular seasoning will prevent rust and maintain the pan's non-stick properties.

ribbed grill pan. Soaking the pan in warm, soapy water after use can help loosen any stubborn bits, while regular seasoning will prevent rust and maintain the pan's non-stick properties.

However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed

However, with proper care and maintenance, this issue can easily be managed However, with proper care and maintenance, this issue can easily be managed ribbed grill pan. Soaking the pan in warm, soapy water after use can help loosen any stubborn bits, while regular seasoning will prevent rust and maintain the pan's non-stick properties.

ribbed grill pan. Soaking the pan in warm, soapy water after use can help loosen any stubborn bits, while regular seasoning will prevent rust and maintain the pan's non-stick properties.