Current location:Home > price of oil seal >

price of oil seal

2025-08-14 22:20

2025-08-14 22:19

2025-08-14 22:15

2025-08-14 21:33

2025-08-14 21:14

...

2025-08-14 21:03

...

2025-08-14 20:55

2025-08-14 20:53

2025-08-14 20:45

2025-08-14 20:32

Latest articles

Replacing the seals in a hydraulic cylinder using a seal kit is a straightforward process that can be done by maintenance personnel or technicians with basic knowledge of hydraulic systems. By following the instructions provided with the kit and using the appropriate tools, the old seals can be removed, and the new ones installed in a matter of hours.

seal kit for cylinder

Regular inspection and maintenance of the front wheel oil seal are crucial to ensure its proper functioning. Signs of a damaged or worn-out oil seal include oil leaks around the front wheel hub, increased noise or vibration when driving, or uneven tire wear

front wheel oil seal. If any of these symptoms are observed, it is important to replace the front wheel oil seal promptly to prevent further damage to the vehicle.

front wheel oil seal. If any of these symptoms are observed, it is important to replace the front wheel oil seal promptly to prevent further damage to the vehicle.

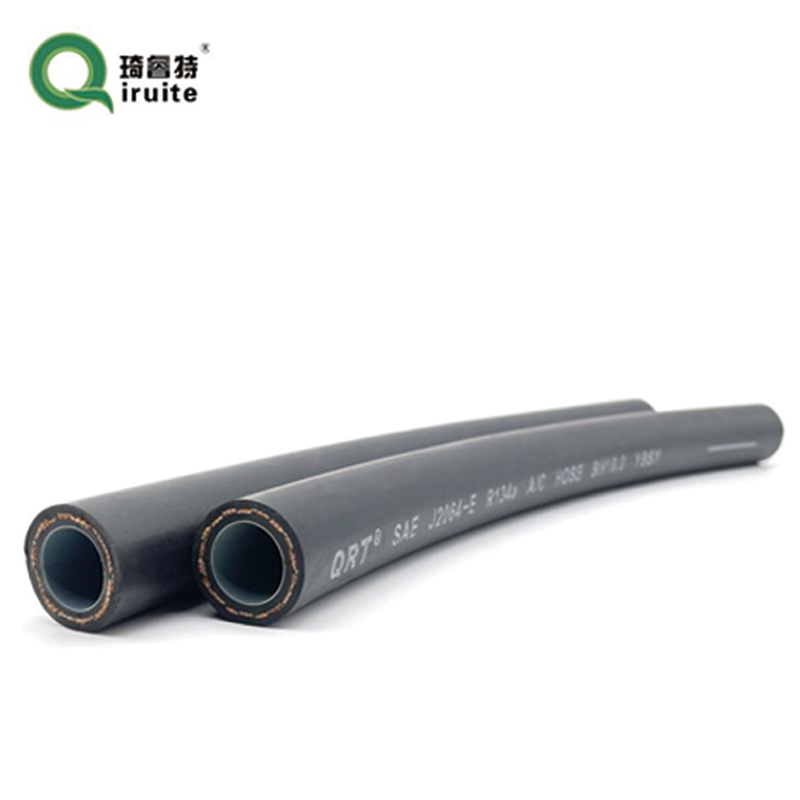

2. Attach the quick-connect fitting on the R134a fill hose to the refrigerant port

r134a fill hose. Ensure that the fitting is securely attached to prevent leaks.

r134a fill hose. Ensure that the fitting is securely attached to prevent leaks.

After the damaged section of the power steering pipe has been removed, a new section of pipe can be installed

repair power steering pipe. It is important to ensure that the new section of pipe is the correct size and length to ensure a proper fit. The new section of pipe should be securely connected to the existing power steering system using hose clamps or fittings.

repair power steering pipe. It is important to ensure that the new section of pipe is the correct size and length to ensure a proper fit. The new section of pipe should be securely connected to the existing power steering system using hose clamps or fittings.

Threaded pipe connectors come in a variety of materials, including stainless steel, brass, and PVC, to suit different applications. Stainless steel connectors are ideal for corrosive environments, while brass connectors are commonly used in plumbing systems. PVC connectors are lightweight and resistant to corrosion, making them suitable for water and wastewater applications.