Hebei Hankai tcn type oil seal

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes. Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel

Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel Signs of a failing oil seal include visible oil stains under the car, unusual noises during steering, or a wandering steering wheel front hub oil seal. If detected early, these issues can be addressed before they escalate into more significant problems.

front hub oil seal. If detected early, these issues can be addressed before they escalate into more significant problems. hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.

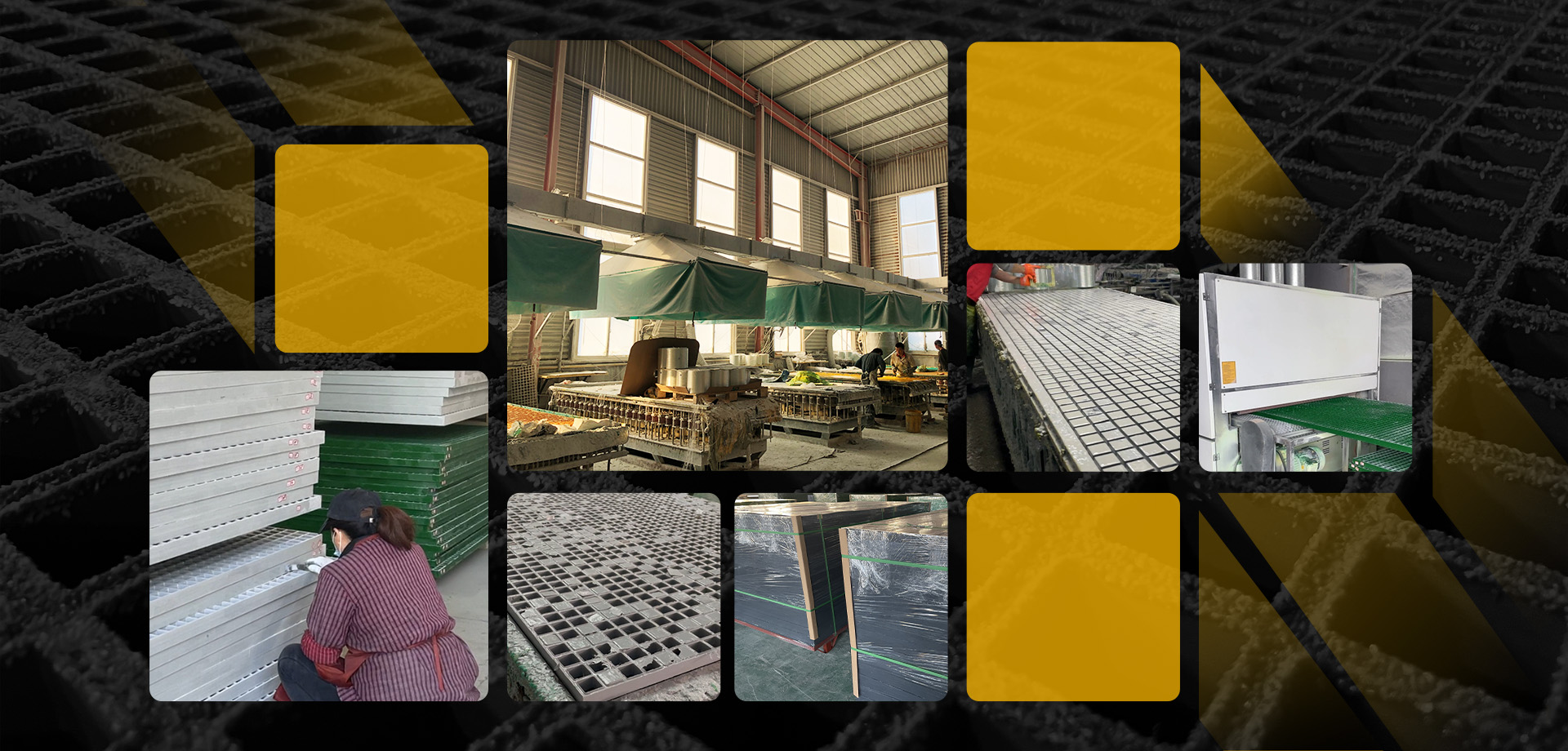

hydraulic cylinder oil seal kit. It's vital to select seals that are compatible with the hydraulic oil to avoid degradation and ensure optimal sealing performance. Furthermore, seals should be able to withstand the environmental conditions they will be subjected to, such as exposure to dust, dirt, or extreme temperatures.Another characteristic that sets FRP grating apart is its lightweight nature. Weighing significantly less than metal grating, FRP is easier to handle and install, minimizing labor costs and time during construction and maintenance projects. This intrinsic property also facilitates the design of structures with less supporting infrastructure, such as frames and beams, further contributing to overall project efficiency. The ease of installation and reduced weight makes it a favorite amongst engineers and contractors looking for cost-effective solutions without compromising strength.

fibreglass reinforced plastic grating

The operational mechanism of a carbon filter vessel is relatively straightforward. When air or water flows through the vessel, contaminants come into contact with the surface of the activated carbon. Due to the unique properties of activated carbon, such as its large surface area and high porosity, a significant number of contaminants can be captured. The effectiveness of a carbon filter vessel largely depends on factors such as the quality of the activated carbon, the flow rate of the liquid or gas, and the characteristics of the contaminants being filtered.