Current location:Home > hydraulic gear pump seals >

hydraulic gear pump seals

2025-08-15 03:00

Repairing a bottle jack might seem daunting at first, but with a dedicated repair kit, the process becomes streamlined. The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement

The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement bottle jack repair kits. For instance, if the piston seal is compromised, causing the jack to leak oil or fail to lift properly, the repair kit will often include a high-quality replacement that can restore the jack's functionality within minutes.

bottle jack repair kits. For instance, if the piston seal is compromised, causing the jack to leak oil or fail to lift properly, the repair kit will often include a high-quality replacement that can restore the jack's functionality within minutes.

The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement

The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement The kits are designed to identify common issues such as worn-out seals or damaged components and provide the necessary parts for a straightforward replacement bottle jack repair kits. For instance, if the piston seal is compromised, causing the jack to leak oil or fail to lift properly, the repair kit will often include a high-quality replacement that can restore the jack's functionality within minutes.

bottle jack repair kits. For instance, if the piston seal is compromised, causing the jack to leak oil or fail to lift properly, the repair kit will often include a high-quality replacement that can restore the jack's functionality within minutes.

...

2025-08-15 02:57

2025-08-15 02:46

2025-08-15 02:38

2025-08-15 02:35

2025-08-15 02:23

...

2025-08-15 02:19

2025-08-15 00:56

2025-08-15 00:42

2025-08-15 00:30

Latest articles

In industries like automotive, aerospace, and manufacturing, where precision and reliability are crucial, the quality of oil seals cannot be overstated. In automotive engines, for example, oil seals ensure that engine oil stays within the system, lubricating moving parts and preventing costly damage. In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations industrial oil seals.

industrial oil seals.

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations industrial oil seals.

industrial oil seals.2. Design Specifications The unique design aspects, such as the sealing lip geometry and the hardness of the rubber, are optimized to balance flexibility and resilience. This design ensures proper contact with the shaft, reducing the risk of oil leakage and improving the overall efficiency of the machinery.

25 35 7 oil seal

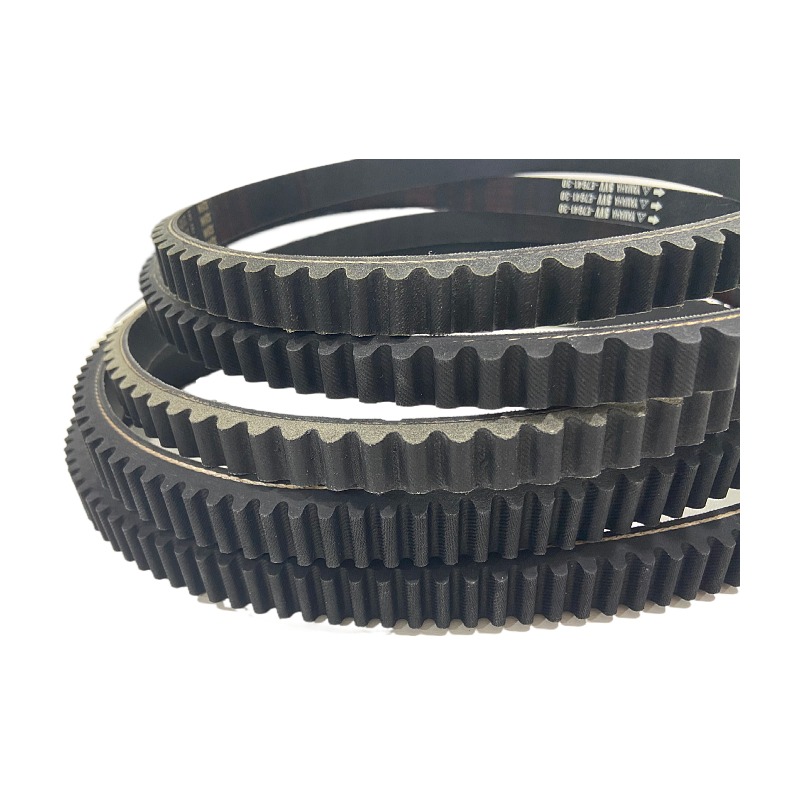

In industrial settings, rubber belts may be found in conveyor systems, allowing for the continuous movement of goods, or in pumps where power must be transmitted efficiently over larger distances. The versatility of rubber belts makes them suitable for a wide array of applications beyond household appliances.

washing machine belt v rubber