Current location:Home > hydraulic cylinder seal kits suppliers >

hydraulic cylinder seal kits suppliers

2025-08-14 04:09

2025-08-14 04:04

2025-08-14 04:00

2025-08-14 03:15

The primary function of these seals is to prevent oil leakage, which not only maintains the system's pressure but also conserves the oil, reducing the need for frequent refills. They also prevent the ingress of contaminants like dust, dirt, or moisture, which could damage the motor or degrade the oil quality. Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction

Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction hydraulic motor oil seal.

hydraulic motor oil seal.

Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction

Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction Moreover, they contribute to the overall efficiency of the system by minimizing power loss due to fluid friction hydraulic motor oil seal.

hydraulic motor oil seal.

...

2025-08-14 02:50

2025-08-14 02:43

2025-08-14 02:36

2025-08-14 02:29

2025-08-14 01:56

There are various types of hydraulic dust seals available, including piston seals, rod seals, and wiper seals. Each type serves a specific purpose in maintaining the cleanliness and efficiency of hydraulic systems. For example, piston seals are used to prevent fluid leakage and contamination around the piston, while rod seals prevent fluid leakage along the rod in hydraulic cylinders

hydraulic dust seal. Wiper seals, on the other hand, are designed to wipe away dirt and debris from the rod before it enters the hydraulic system.

hydraulic dust seal. Wiper seals, on the other hand, are designed to wipe away dirt and debris from the rod before it enters the hydraulic system.

...

2025-08-14 01:55

Latest articles

In addition to withstanding high temperatures, these seals must also be resistant to corrosion and wear. They are often exposed to harsh chemicals or abrasive materials, so they need to be able to hold up under these conditions without deteriorating over time

high temperature shaft seals.

high temperature shaft seals.

Another important aspect of industrial oil seals is their ease of installation and maintenance industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.

industrial oil seals. These seals are typically designed for easy replacement, allowing for quick and efficient servicing of the machinery. Regular maintenance of oil seals can help to prevent leaks and extend the lifespan of the machinery, reducing the risk of costly repairs and downtime.The design and material selection of high pressure shaft seals are crucial for their performance high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.The importance of oil seals in hydraulic systems cannot be overstated oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

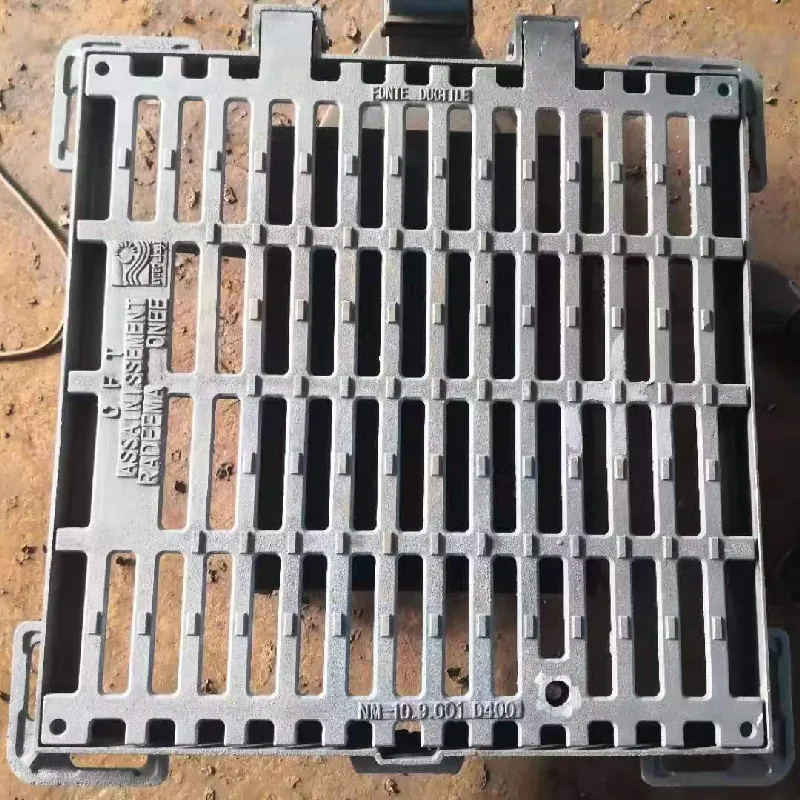

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.Another significant advantage of ductile iron covers and frames is their resistance to corrosion. Urban environments expose infrastructure to various corrosive elements, including chemicals from roadways, saline environments, and environmental pollutants. Ductile iron can be coated with protective finishes, such as asphalt or epoxy, to further enhance its corrosion resistance. This quality extends the life of the product substantially, reducing the need for frequent repairs or replacements and thereby resulting in cost savings for municipalities and contractors.

ductile iron cover and frame